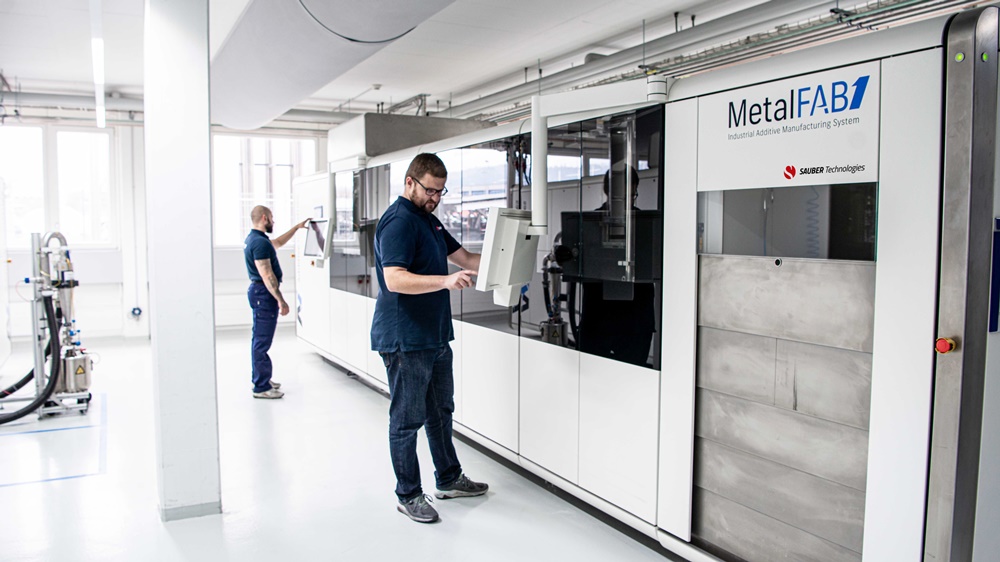

EINDHOVEN, The Netherlands and HINWIL, Switzerland, Jul 21, 2022 – Sauber Technologies and Alfa Romeo F1 Team ORLEN have extended their technology partnership with Additive Industries for another three years. Sauber Technologies has been using Additive Industries’ MetalFAB platform for additive manufacturing since 2017, with a current count of four systems in-house. This summer, both parties celebrate the fifth anniversary of their long-term strategic metal additive manufacturing partnership. With the focus of both parties on productivity, part reproducibility and industrial series production, they are eager to keep pushing boundaries in metal AM to manufacture light weight crucial components for the automotive, industrial & tooling industries.

From the start of the collaboration, Additive Industries has enabled the professionals of Sauber Technologies to accelerate in the metal additive manufacturing domain. The investment in the MetalFAB systems – with its unique open parameters – allowed Sauber to reduce cycle times in the manufacturing of innovative parts for their own wind tunnel models, F1 race cars as well as third party business.

Sauber Technologies is part of the Sauber Group and based in Hinwil, Switzerland. The company is fully focused on third-party business, providing a holistic service for complex engineering problems, from the idea stage to the finished products. The company can draw on the experience of its dedicated, highly skilled staff and from the know-how generated in fifty years of history in motorsport. Sauber is widely known for its racing activities, including sports car racing and Formula 1. Sauber is competing in the F1 competition with its Alfa Romeo F1 Team ORLEN with drivers Valtteri Bottas and Zhou Guanyu.

Christoph Hansen, COO of Sauber Technologies: “Over the course of our successful partnership, Additive Industries have become an essential ingredient in the offering of Sauber Technologies. Ever since we introduced the MetalFAB systems to our processes, our in-house capabilities have increased in a significant way: Additive Industries continues to provide us with the best way to manufacture the most advanced parts for our motorsport operations, as well as our growing cohort of customers, reducing lead times, costs and waste while pushing forward the boundaries of technology.”

Mark Massey, Chief Commercial Officer (CCO) at Additive Industries: “We are very proud to be constantly recognized by Sauber Technologies for our class-leading automated industrial metal additive manufacturing solutions. We encourage each other to push our boundaries and to innovate. We are committed to continuing our long-term partnership grow and evolve in the coming years.”

About Additive Industries

Additive Industries is a 3D metal printer manufacturer for high-quality metal parts. It offers a system specifically aimed at high-end and demanding industrial markets. With class-leading build volume, robustness as well as productivity, Additive Industries redefines the business case for aerospace, automotive, energy and high-tech equipment. Headquartered in the Netherlands, Additive Industries has demo and service centers in the USA, UK and Singapore and is a global key player in large volume metal printing systems. For more information, visit https://www.additiveindustries.com/

About Sauber Technologies AG

Sauber Technologies, a subsidiary of the Sauber Group based in Hinwil, Switzerland, is a company devoted to bringing Sauber’s drive for cutting-edge innovation and its Formula One mindset to businesses all over the world. Offering services and know-how to a wide range of markets, the company draws on the experience of its dedicated, highly-skilled staff and on the knowledge matured in 50 years of history in motorsport to provide a holistic service for complex engineering problems, from the idea stage to the finished products. Its first-grade equipment and facilities enable Sauber Technologies to deliver world-class expertise in fields as varied as aerodynamics, lightweight design and CFK design and calculation. The company’s customer will have access to high-quality mechatronic systems design and production, fluid and thermal simulations and structural analysis, as well as a tried-and-tested approach to additive manufacturing, including prototyping and serial production, courtesy of the biggest additive manufacturing machine park in Switzerland. For more information www.sauber-technologies.com.