Mold Tryouts are conducted after the mold is completed and before the mass production of injection molded products. At this stage, different molding parameters must be tested repetitively for the optimal settings. Thus, we will be able to acquire products that can meet our needs and proceed mass production with the highest efficiency. In addition to adopting the CAE simulation results and referring to the machine characteristics, we also must rely on experts’ experience to find the optimized parameters. However, without the leadership of the experts, and when the historical data is mostly recorded on paper, it is not easy to sort out useful data and will waste a lot of time and resources.

To efficiently manage and access data, digitalization and storing it on cloud are necessary. Thus, we can directly access the historical experiences through analytics and the data visualization tools without relying on experts. The iSLM Mold Tryout Management is the cloud-based platform designed for the mold tryout workflow. It not only helps enterprises digitalize the big data, but also provides the feature for comparing the experimental and CAE data (Fig. 1).

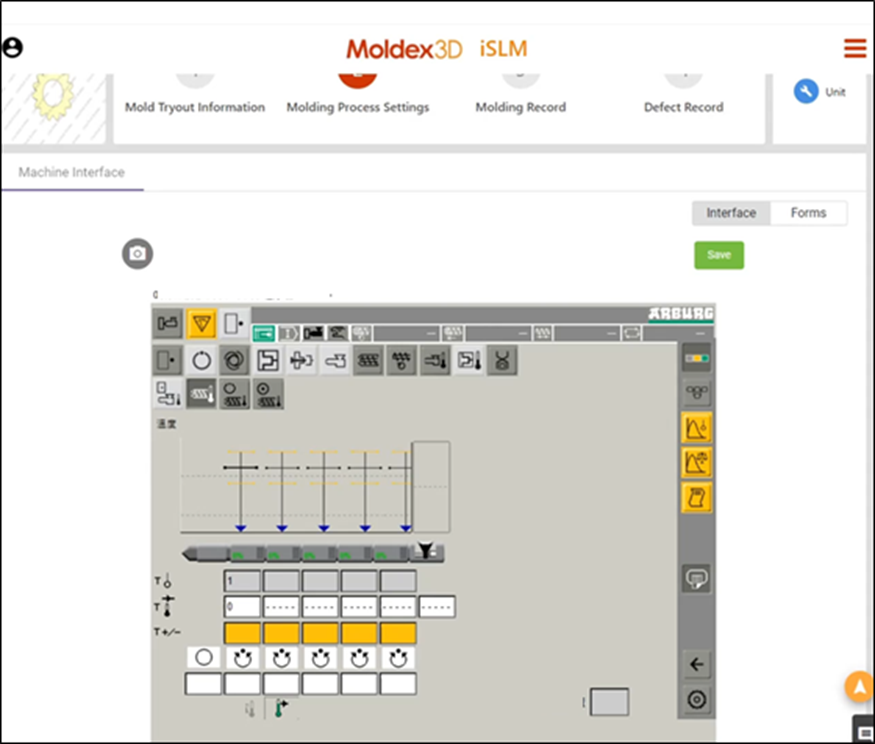

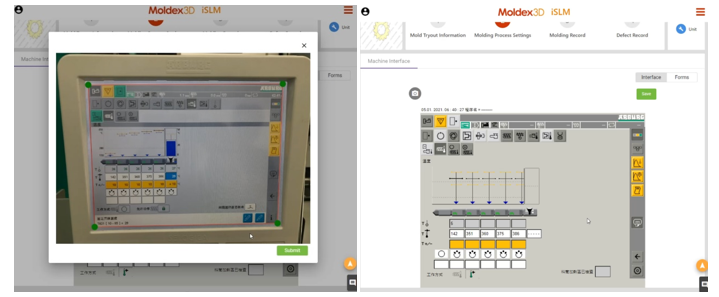

The iSLM Mold Tryout Management provides standardized recording processes for mold tryouts. The on-site operation engineer can accurately record the important parameters of injection molding by corresponding to their working progress. To enable the engineers to record mold tryout data more easily, the iSLM Mold Tryout Management also provides a user interface approaching that of a real on-site injection machine (Fig2), which greatly simplifies the process of matching the form columns with the real machine. In addition, its Optical Character Recognition (OCR) model developed through the deep learning technology enables users to directly record by taking pictures (Fig. 3).

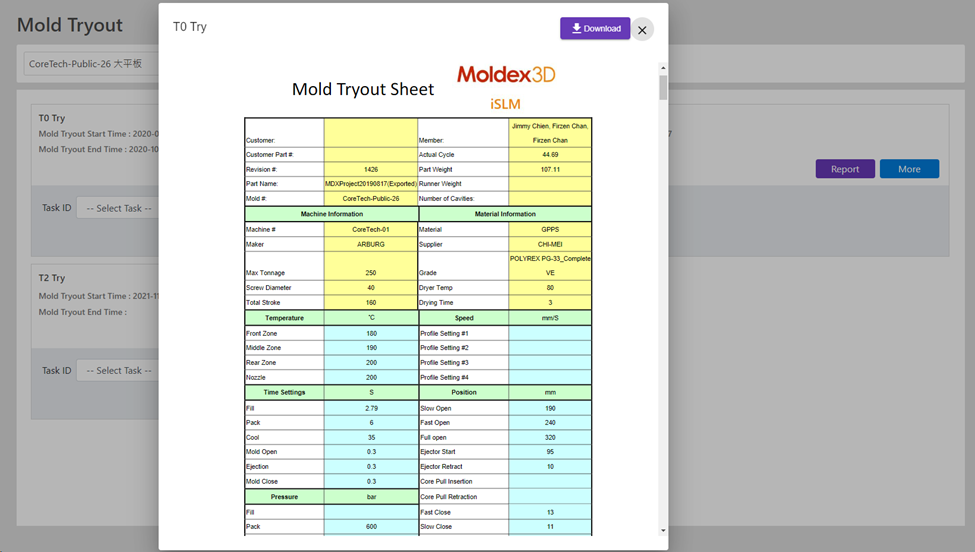

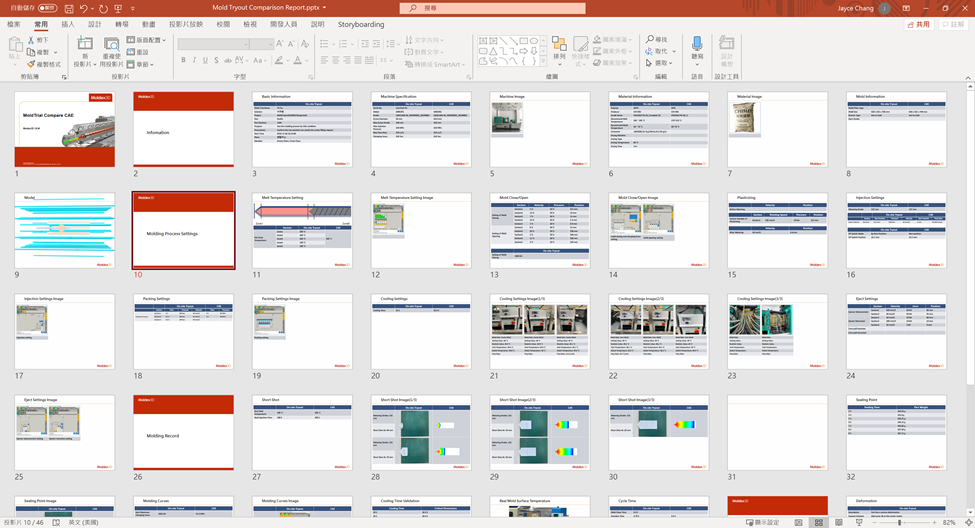

After mold tryout recordings, iSLM also provides a mold tryout form customization feature, which can convert the recording into a mold tryout report and output it based on the traditional form format, so that users can read the data in their familiar format (Fig. 4).

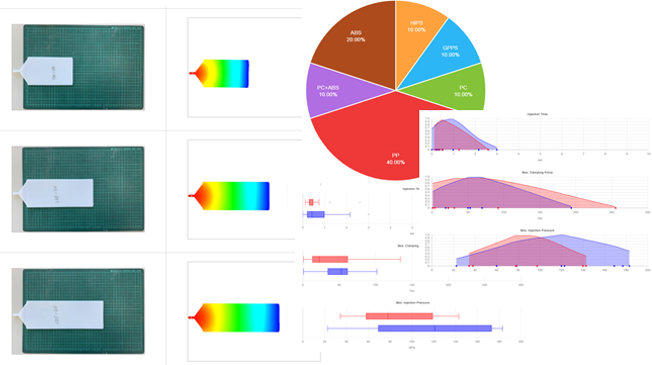

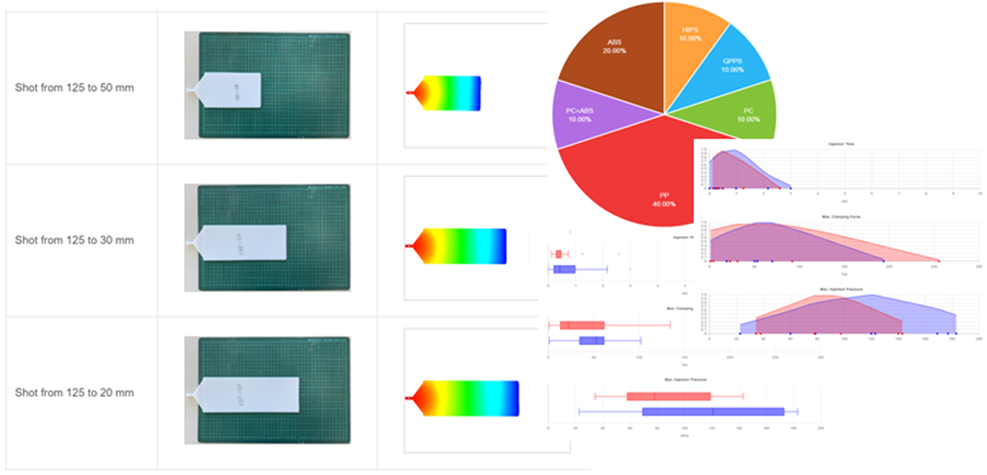

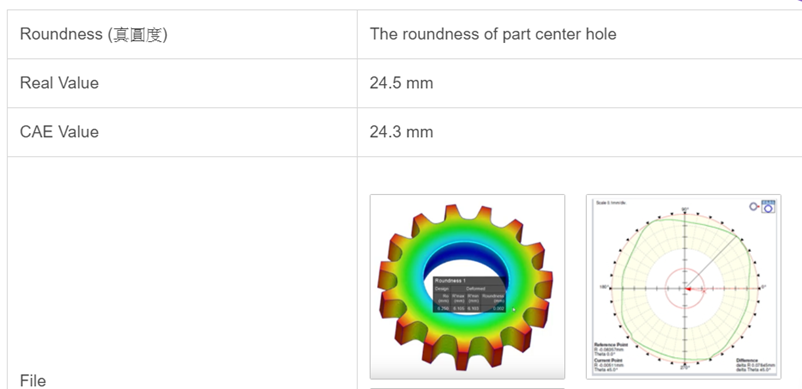

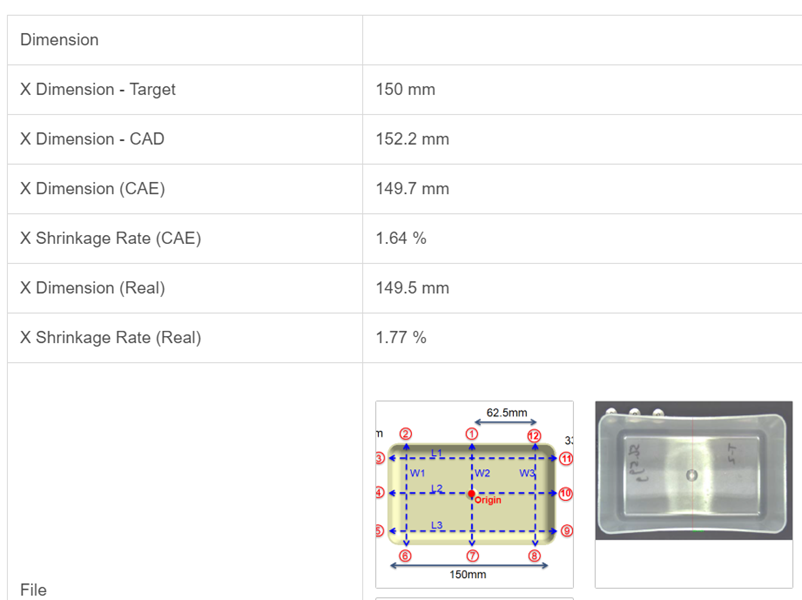

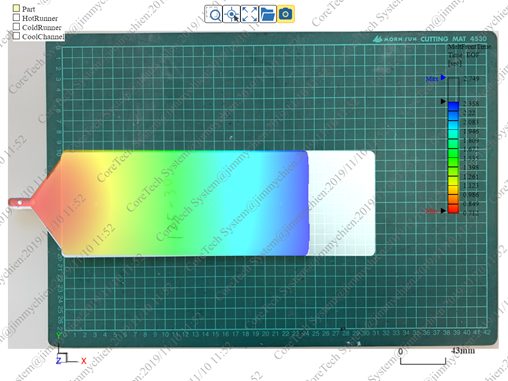

When the mold tryout is completed, it is not applicable to visually inspect the products surface and quality, or measure the key area dimensions through the measuring instrument. The reason is, both methods cannot be comprehensively compared with the CAD files drawn by the CAD engineers and the analysis results from the CAE engineers. On the other hand, the iSLM Mold Tryout Management can record not only the molding parameters of the mold tryouts, but also the quality of the product (Fig. 5). Moreover, it can compare it with the CAD or CAE results for different quality factors or test results (Fig. 6).

Lastly, mold engineers need to make reports or present to their supervisors. It used to take a lot of time to organize the data, even if it has been stored on the web platform. To overcome this, the iSLM Mold Tryout Management provides the PowerPoint report generation function, containing the comparison of the complete mold tryout recordings and CAE results (Fig. 7).

Introducing the iSLM platform, enterprises will be able to break the barriers for engineers to enter the production line through systematic management, and greatly reduce the effort on document processing. It enables enterprises to effectively utilize historical data for high-efficiency production.

For more details visit – https://www.moldex3d.com/