New Tough Resins match HDPE, ABS, and polypropylene performance for end-use production

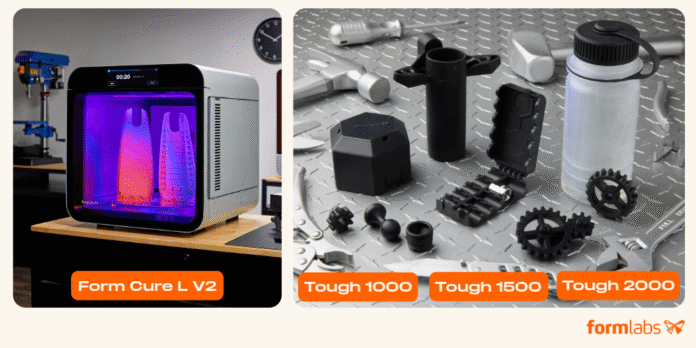

Somerville, MA, November 13, 2025 – Formlabs, the leader in 3D printing, today announced two new SLA materials that bring 3D printing significantly closer to being a manufacturing method for end-use part production. Tough 1000 Resin and a significantly improved Tough 2000 Resin join Tough 1500 Resin, forming the new Tough Resin Family. These tough, resilient engineering materials stand up to harsh environments, impact, and repeated wear, all while delivering a dark, matte surface finish with crisp details when printed on Form 4 Series 3D printers.

Thermoplastics are strong, durable, and long-lasting, and the next-generation Formlabs Tough Resins rival these materials. Each of the resins in the Tough Resin Family are named after the tensile modulus of the material and matches the properties of specific benchmark thermoplastics:

- Tough 1000 Resin is the toughest and most ductile material in the new Tough family, rivaling HDPE.

- Tough 1500 Resin is a balanced blend of stiffness and compliance, rivaling polypropylene.

- Tough 2000 Resin is the strongest and stiffest, rivaling ABS.

“Formlabs’ goal has always been to deliver any part at the push of a button,” Formlabs co-founder and CEO Max Lobovsky said. “But that mission depends on more than just speed and ease. We need parts that are as tough and resilient as the products we rely on every day. With the new Tough Resin Family, SLA printing now delivers the strength and durability of the world’s most trusted thermoplastics.”

Early users have already seen how well parts printed in the new Tough materials hold up in real-world applications.

“The end-use products that we are offering need to be able to withstand our torture testing at freezing temperatures. These parts need to be able to take abuse, and Tough 1000 holds up,” said Adam Warren, Draftsman and Mechanical Designer at Cool Machines.

Blazing Fast Post-Curing of Large Parts With Form Cure L V2

Formlabs also introduced Form Cure L V2, a new large-format curing unit compatible with all parts printed on large format SLA printers like the Form 4L. It post-cures most parts in under 60 seconds, offering a faster, more compact, and streamlined post-processing experience.

This streamlined post-processing workflow has already helped customers iterate more quickly and dramatically increase throughput.

“We were shocked by how fast the cure times were across all materials, even the engineering resins, which allowed us to work faster and get finished parts to our engineers in less time,” said Agostino Lobello, Product Development Engineer at Radio Flyer.

New PreForm Features Streamline Workflows

PreForm 3.54 introduces new software features for both the Form Series 3D printers and Fuse Series 3D printers, making workflows faster, easier, and more streamlined. New features include:

- Supports V2

- Measuring Tools

- CAD assembly import improvements

- Improved build packing tools

- UX and navigation improvements

With these updates, users can focus more on design and problem-solving, not on support, imports, or packing.

For any enquiries, please contact Formlabs at apac.sales@formlabs.com

About Formlabs

Formlabs builds the tools that make it possible for anyone to bring their ideas to life. Headquartered in Somerville, Mass., with offices across the globe, Formlabs is the professional 3D printer of choice for engineers, designers, healthcare providers, manufacturers, and decision-makers. Formlabs’ products include SLA and SLS 3D printers, post-processing solutions, best-in-class software, and over 45 materials to suit dozens of applications. In 2024, Formlabs was named one of the world’s Most Innovative Companies in Manufacturing by Fast Company. To learn more, visit https://formlabs.com/global/