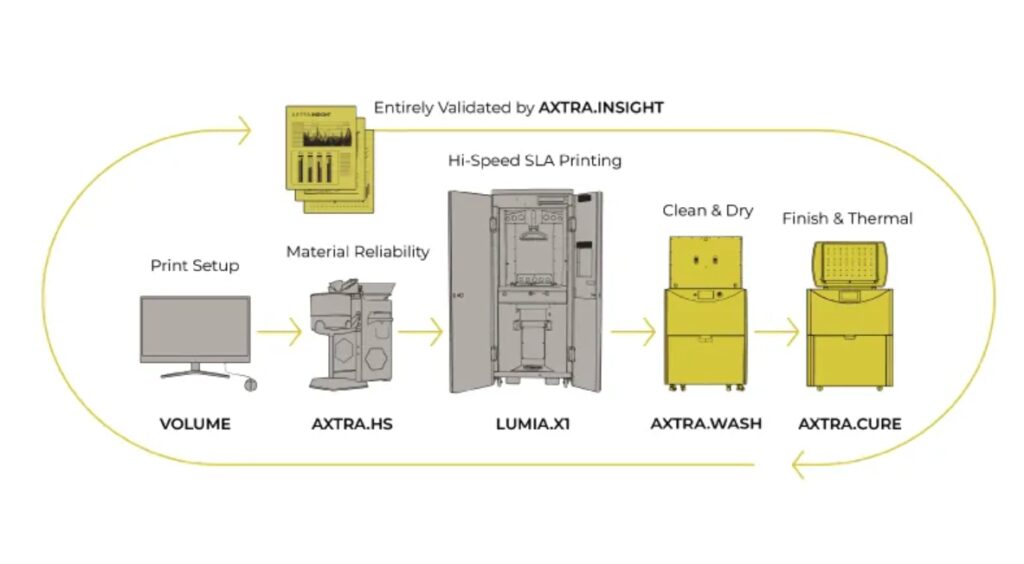

CHARLOTTE, NC, USA, Nov 25, 2025 – Axtra3D announces Axtra Workflow, a fully connected and validated end-to-end additive manufacturing ecosystem that links build setup, printing, post-processing, inspection, and data-driven traceability into a single production backbone.

The company is launching three new post-processing and analytics products as part of the workflow: Axtra.Wash, Axtra.Cure and Axtra.Insight while introducing major improvements to the LumiaX1 printer and Volume build-prep software.

The workflow delivers a step change in repeatability, throughput, and qualification readiness for industrial, dental, aerospace and tooling manufacturers.

“Manufacturers need more than one-off print wins. They need validated, repeatable workflows that scale from prototype to production. Axtra Workflow solves that problem by tightly integrating printing and processing hardware, materials, and software into a learning, traceable production system,” says Rajeev Kulkarni, Chief Strategy Officer, Axtra3D.

Rajeev adds, “With the new products, and the workflow intelligence from Axtra.Insight, users benefit from a fully connected and validated setup from design to final product. It reduces errors and rework, streamlines throughput, enhances part quality, and facilitates traceability for regulatory compliance and quality assurance.

It truly enables scalable, repeatable production for any batch size.”

Key Announcement Highlights

• Axtra Workflow is a fully connected, validated process that ties together build setup, Hybrid PhotoSynthesis (HPS) printing, automated wash and dry, UV and thermal cure, and per-layer analytics. The workflow reduces variation by optimizing each stage holistically, delivering traceable production records.

• Axtra.Wash & Axtra.Cure are new additions to the portfolio. Each product is designed and validated to operate within the Axtra Workflow ecosystem, while also supporting interoperability with other OEM systems where appropriate. Axtra.Wash is a fully automated wash and dry station that supports up to three cleaning agents across multiple tanks, which imports validated material-specific wash/dry profiles from the software and printer to reduce manual guesswork. Axtra.Cure is a combined UV and thermal curing system that consolidates post-cure and heat treatment in a single device. The UV chamber provides three independently controlled wavelength bands (355, 385, 405 nm) with dual photosensor verification and up to 250 °C thermal cycles.

• Axtra.Insight is a process visibility and connectivity platform. It provides real-time process visibility and analytics platform that aggregates data from more than 155 onboard and peripheral sensors across the entire workflow. It delivers layer-level process monitoring, predictive maintenance, MES integration, fleet reporting, and complete job history exports for quality systems. The platform correlates TruLayer and HPS sensor data for auditable production outcomes.

• LumiaX1 3D Printer v25 printer has been upgraded and improved with enhanced TruLayer hardware, advanced linear sensing, refined encoder and gantry control, automatic Z recalibration, and a modern HMI that exposes live sensor matrices for real-time visibility.

• Volume Print Setup Software v25 now includes a native laser and DLP slicing engine, eliminating the HPS Bridge for streamlined job prep and transfer. It also adds centralized printer fleet management, editable and savable print profiles, advanced shrinkage and beam compensation controls, and support for hybrid DLP/HPS workflows.

Why Axtra Workflow and Axtra Insight Matters?

Manufacturers often lose production readiness to variability across disconnected systems, material handling practices, and ad hoc post-processing.

Axtra Workflow addresses this by delivering:

- Holistic optimization. Material profiles, printer parameters, wash and cure recipes are created and validated together preventing mismatch and revalidation overhead.

- Traceability and compliance. Per-layer sensor capture, process certification and complete job histories enable repeatable production for regulated and end-use applications.

- Scalability and automation. Connected print, wash, cure, reduce labor, shrink lead time, and make production growth practical.

- Faster material adoption. Validated workflows reduce the effort and risk of introducing new resins or geometries to production.

Axtra.Insight, along with the updated LumiaX1 and Volume Software, is available now as part of the Axtra portfolio.

Pre-orders for Axtra.Wash and Axtra.Cure open immediately. Shipping is scheduled to begin at the start of Q2 2026.

About Axtra3D

Based in the US and Italy, Axtra3D is a global company specializing in Hi-Speed SLA systems that eliminates tradeoffs between print throughput, accuracy, feature resolution, and surface finish, typically found in traditional SLA or DLP systems.

The flagship LumiaX1 Hi-Speed SLA system by Axtra3D represents a significant advancement, combining its Hybrid PhotoSynthesis resin polymerization process with TruLayer, a layer separation technology. HPS utilizes both a laser and a DLP to image simultaneously, while TruLayer enables rapid detachment of the active print layer, resulting in a 20X throughput improvement while preserving the accuracy and fidelity of SLA parts.

Axtra3D operates with two business models.

Axtra Solutions™: This model provides fully optimized, turnkey 3D printing solutions. Customers receive complete print profiles fine-tuned for maximum performance and reliability, supported by Axtra3D’s Applications team and quality material partners.

Axtra OpenAccess: This model further builds on Axtra Solutions™ and allows customers the flexibility to experiment with new materials and applications. It supports innovation and adaptability, enabling added flexibility.

Learn more at https://axtra3d.com.