SHEFFIELD, UK, Dec 4, 2025 – MachineWorks and Hwacheon announce the integration of the market leading MachineWorks CNC simulation and verification libraries into Hwacheon’s latest Harmony smart control.

With a clear and bright 19” TFT LED touchscreen display, the latest Harmony control has been designed to be very easy and intuitive to use, with Hwacheon’s designers aiming for ‘smartphone’ levels of usability. The reception from users has been positive, with feedback such as “you just know which buttons to push.”

Hwacheon have been developing control software since 2012, and so despite the groundbreaking new user experience, much of the software internal to the control has been battle tested over the last decade. The Harmony series was first launched in 2022 in the US but the latest version is a significant upgrade.

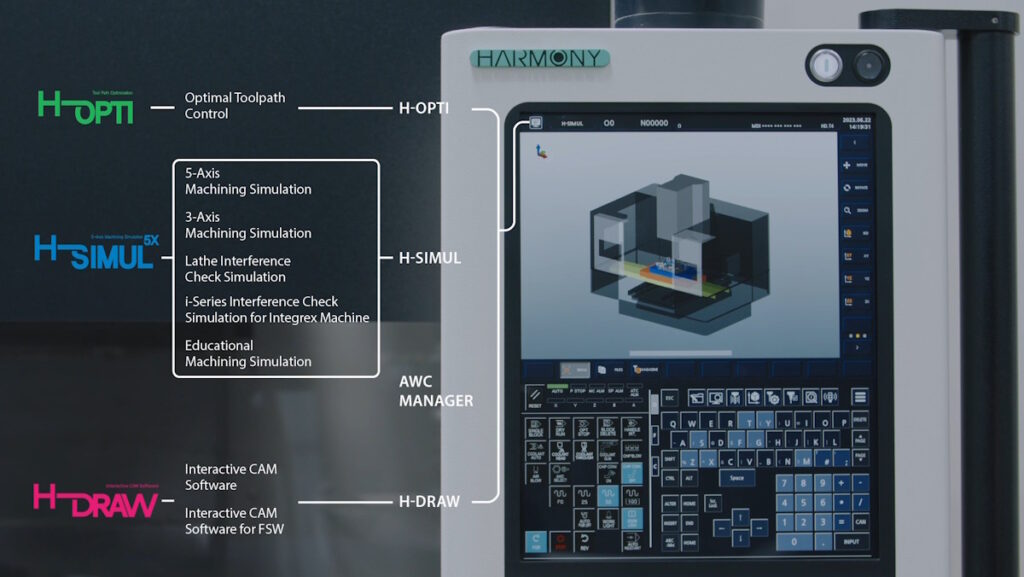

The control comes with a host of features as standard including conversational programming work scheduling, probing support, toolpath optimization and the advanced, real-time, collision avoidance system based on MachineWorks.

Apps included on the control include H-Simul and H-Opti.

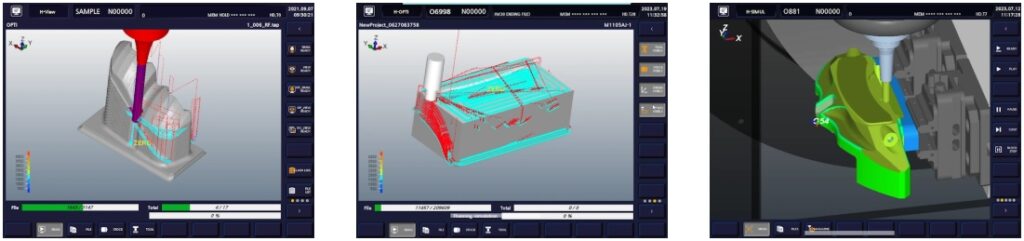

- G-code based simulation

- Automatic registration and generation of materials from CAD data

- Easy setup of fixtures from external files

- Generation of hexagon and column fixtures

- Full machine collision checking using MachineWorks’ sweep-based collision check

- Undercut (rest) and overcut (gouge) detection

- Highly accurate, stable and performant simulation

H-Opti provides a range of toolpath optimization strategies, including:

- Feed rate optimization based on cutting amounts, preventing tool damage and extending the tool’s usable lifetime

- Adjustments for overloaded and underloaded regions

- Rapid feed collision detection and correction

- Undercut (rest) and overcut (gouge) detection

The new control is being provided as standard on Hwacheon’s i2 Multi-tasking machine and M1-5AX 5-axis machining centre, and Hwacheon expects the control to be added to more of their most advanced machines in future.

“Hwacheon prides itself on delivering high quality, high accuracy products. After testing many systems we found the material removal and collision detection algorithms in the MachineWorks libraries to be the most advanced available on the market. Their team of geometry experts are responsive, knowledgeable and available to help, and it has been a pleasure to work with them,” commented Daeyu Park, the Director of Hwacheon’s Software R&D center.

Dr Fenqiang Lin, the Managing Director of MachineWorks said “Hwacheon’s new HMI looks really great. Hwacheon and MachineWorks have been working as partners for over a decade now. MachineWorks is proud to support Hwacheon as it brings new and advanced innovations that will improve the competitiveness of their customer’s businesses.”

About Hwacheon

Founded in 1945 by Honorary Chairman Kwon Seung Gwan, Hwacheon is a pioneer and leader in the Korean machine tool industry. They are one of the first companies in the world to develop smart operating systems and automation software for our CNC machine tools. Backed by over half a century of experience, Hwacheon’s strength also lies in the deep vertical integration of CNC machine tool manufacturing.

Hwacheon prides itself on being a future-oriented, technologically advanced expert in the machining industry; Hwacheon develops a range of advanced machining centres for milling and turning, including large-sized machines used in shipbuilding, plants and aircraft as well as the power generation and energy industries.

Hwacheon’s machining products are developed to the highest precision and quality standards, and their SMART Machine concept integrates advanced software with machining expertise and top-tier automation. For more information, visit https://www.hwacheon.com.

About MachineWorks Ltd

MachineWorks Ltd has been providing advanced 3D software engines to manufacturers and engineering software developers since 1994.

MachineWorks is the leading toolkit for CNC simulation and verification and is supplied embedded within a wide range of brands from major machine tools and CNC controller manufacturers and CAM software vendors. With over fifty major OEM licensees, Polygonica is the leading engine for polygon-mesh modelling and is widely used in a range of markets, including CAD, CAM, CAE, and AM, along with Medical, Dental, EDA, Metrology, AEC, Construction, Mining, and other large capital asset industries.

Companies who integrate MachineWorks’ components into their software solutions include Dassault Systemes, Autodesk, Hexagon MI, ANSYS, Synopsys, AECOM, 3D Systems, Stratasys, OpenMind, CAMBRIO, Desktop Metal, Nexa3D, Heidenhain, Okuma, DMG Mori, HCL, SolidCAM, Convergent Science, SimScale, Topsolid, ZWSoft, Diota, CASTOR, CADS Additive, Intech Additive Solutions, and Go2CAM. For more information, visit www.machineworks.com or www.polygonica.com.