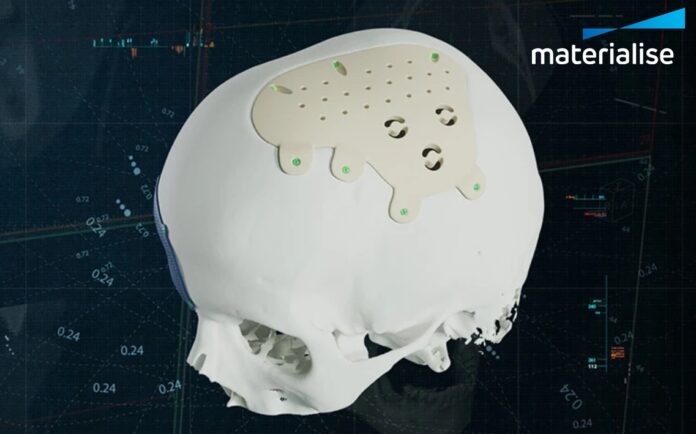

LEUVEN, Belgium, Feb 18, 2026 — Materialise NV, a global leader in personalized medical solutions, today announced the addition of PEEK (polyetheretherketone) implants to its cranio-maxillofacial (CMF) portfolio. The expansion provides surgeons with the flexibility to choose between titanium and PEEK for patient-specific reconstructions, while maintaining the continuity of Materialise’s integrated digital ecosystem — one planning session, one workflow, one partner.

The custom-made PEEK implants are fully integrated into the company’s established CMF portfolio, which includes collaborative 3D planning with dedicated clinical engineers in Mimics Enlight CMF software, seamless case management through Mimics Flow, and fixation with Materialise Standard+ Solutions. This continuity ensures surgeons can select the appropriate material for each clinical indication while maintaining the same validated, traceable process they rely on.

“Personalization isn’t just about material choices but about the precision of the planning process and the reliability of execution,” said Maarten Zandbergen, Market Manager at Materialise. “Our clinical engineers work hand in hand with surgeons to design each implant, and that collaborative approach remains constant whether the case calls for titanium or PEEK. What changes is the surgeon’s freedom to choose; what stays the same is the peace of mind that comes from a proven, end-to-end process.”

Clinical versatility within a trusted framework

The addition of PEEK complements Materialise’s existing titanium 3D printed implant portfolio, providing surgeons with expanded options while maintaining the precision, predictability, and clinical collaboration that define the Materialise approach to personalized CMF surgery.

PEEK’s radiolucent properties make it a preferred choice by many surgeons for cranial reconstruction, as well as facial contour restoration and onlay applications. The material complements titanium’s established role in load-bearing applications, giving surgeons expanded options for addressing diverse patient needs — from artifact-free postoperative imaging to lightweight anatomical restoration.

Each PEEK implant is manufactured in Europe by Ad Mirabiles, Materialise’s experienced manufacturing partner. Ad Mirabiles operates under an EN ISO 13485 certified quality management system and ensures consistent accuracy across every case. Materialise commits to a 72-hour turnaround time for PEEK implants following surgical plan approval, providing the same reliability the company has established with its titanium portfolio.

The custom-made PEEK implants are now available to surgeons across Europe (excluding Switzerland), where Materialise CMF solutions are established.

About Materialise

Materialise incorporates more than three decades of 3D printing experience into a range of software solutions and 3D printing services that empower sustainable 3D printing applications. Our open, secure, and flexible end-to-end solutions enable industrial manufacturing and mass personalization in various industries — including healthcare, automotive, aerospace, eyewear, art and design, wearables, and consumer goods. Headquartered in Belgium and with branches worldwide, Materialise combines the largest group of software developers in the industry with one of the world’s largest and most complete 3D printing facilities. For more information, visit https://www.materialise.com.