CHARLOTTE, NC, USA, Nov 24, 2025 – Axtra3D, Inc., an emerging leader in advanced additive manufacturing, announces the qualification and immediate availability of three functional elastomers.

This milestone expands Axtra Solutions into production-grade elastomers in collaboration with material ecosystem partners Loctite and ForwardAM. The newly qualified materials and solutions, Loctite 3D IND475, Loctite Med414, and Ultracur3D EL 4000 are available for immediate shipment.

Axtra3D’s Head of Materials and Process, Gioia Della Giustina, indicates, “Following our successful launch of TruSil, our true silicone, last year, we saw strong customer demand for an expanded elastomeric portfolio through Axtra Solutions. This growth also strengthens our partnerships with Loctite and ForwardAM, enabling us to expand our material ecosystem that offers the best options in each category.

The LumiaX1 3D Printer distinguishes itself as a highly versatile and differentiated platform, with innovative Hi-Speed SLA technology and access to premium materials. Combining these leading-edge materials with our advanced technologies, strengthens both our Axtra Solutions and Axtra OpenAccess business models. Axtra Solutions delivers fully optimized, end-to-end workflows, while Axtra OpenAccess gives customers the flexibility to experiment with new materials and applications with confidence.

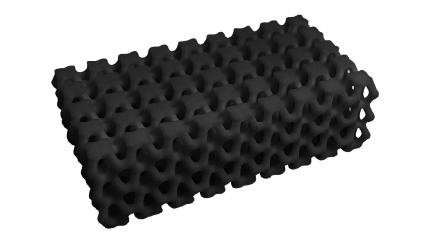

Loctite 3D IND475 is an industrial-strength, single-component, UV resin that cures into a soft Shore 48A hardness elastomer. It delivers true resilience, high energy return, and dependable snap-back performance. It is engineered for applications that demand durability and tear resistance, and it prints efficiently with low-shrinkage behavior. These combined advantages make IND475 a practical choice for production-grade elastomeric parts, including complex lattice structures and functional prototypes. This black material enables high-performance components such as air and dust gaskets, flexible seals and housings, and cushioning pads. Its ability to maintain elastomeric behavior under repeated load makes it a strong fit for both prototyping and end-use environments. This gives manufacturers a reliable elastomer solution that integrates seamlessly into their validated Axtra Solutions workflows.

The second is Loctite 3D Med414, a medical-grade, Shore 50A resin, engineered for elastomeric performance in healthcare environments. This material delivers an exceptional balance of elongation, tear strength, and durability. Its torsional flexibility and true elastomeric behavior make it suitable for components that must withstand repeated movement and skin contact. Offered in blue, Med414 provides a dependable, production-ready option for regulated applications where consistency and safety are essential. Med414’s 240% elongation makes it a strong fit for a wide range of medical and patient-facing end-use elastomeric parts, including soft interface components, skin- contact wearables, flexible seals, and functional medical device elements. Its combination of strength, flexibility, and controlled deformation ensures reliable performance under load.

The third material is the Ultracur3D EL 4000 from ForwardAM. It is a flexible and elastomeric resin engineered for high-performance applications. With superior strength, rebound, and tear resistance, EL 4000 is ideal for parts that require durability and flexibility – including footwear, bike saddles, and cushioning pads. The material delivers high hardness (Shore 90A), exceptional elongation at break (160%), and high tear strength of 49N/mm, making it well-suited for printing intricate, flexible components. This black material provides reliable elastomeric performance for both prototyping and end-use applications.

Gioia further adds, “Expanding our elastomeric portfolio perfectly complements our proven rigid material offerings, giving customers access to a truly comprehensive range of high-performance materials. Together, these materials within Axtra Solutions empower our customers to select the most appropriate material for their specific applications, whether they need performance, precision, flexibility, or durability.”

Availability

All these materials are available for immediate order as part of the Axtra3D portfolio.

About Axtra3D

Based in the US and Italy, Axtra3D is a global company specializing in Hi-Speed SLA systems that eliminates tradeoffs between print throughput, accuracy, feature resolution, and surface finish, typically found in traditional SLA or DLP systems.

The flagship LumiaX1 Hi-Speed SLA system by Axtra3D represents a significant advancement, combining its Hybrid PhotoSynthesis resin polymerization process with TruLayer, a layer separation technology. HPS utilizes both a laser and a DLP to image simultaneously, while TruLayer enables rapid detachment of the active print layer, resulting in a 20X throughput improvement while preserving the accuracy and fidelity of SLA parts.

Axtra3D operates with two business models.

Axtra Solutions™: This model provides fully optimized, turnkey 3D printing solutions. Customers receive complete print profiles fine-tuned for maximum performance and reliability, supported by Axtra3D’s Applications team and quality material partners.

Axtra OpenAccess™: This model further builds on Axtra Solutions™ and allows customers the flexibility to experiment with new materials and applications. It supports innovation and adaptability, enabling added flexibility.

Learn more at https://axtra3d.com.