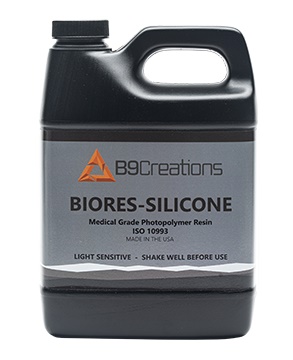

RAPID CITY, SD, USA, Feb 15, 2022 – B9Creations, a global provider of additive manufacturing solutions, launched a brand-new elastomeric resin called BioRes – Silicone. This new addition to its suite of biocompatible 3D printing materials enables customized medical and consumer tech applications for comfortable skin contact products, such as headphones, hearing aids, wristbands, attachments for wearables, silicone components for medical devices, and more.

Offering a unique combination of biocompatibility, high precision, surface finish, and tear resistance, B9Creations’ medical-grade silicone is ISO 90993 certified for prolonged skin contact of up to 30 days.

To check the material data sheet, click here (pdf).

“This material has really opened up our design space. And it’s also saving us a ton of money because we aren’t using pure Teflon, and now we’re able to quickly reiterate designs. So, if there’s a shift in our fixture, we can always compensate and easily make a new one. It has been great for us,” said Kevin Herrera, Senior Engineer specializing in cardiovascular medical devices at Johnson & Johnson.

B9Creations’ medical and industrial silicone materials bend, strength compress, and hold up to repeated cycles without tearing, offering an ideal solution for high-precision parts and ergonomic features as part of larger assemblies.

Coupled with B9Creations’ Core 5 Series Med XL 3D printers, automated cleaning and curing units, biocompatible and engineering resins, and intelligent print preparation software, users can move seamlessly from prototyping to production.

Medical-Grade Technology

With an established reputation as an innovation engine at the forefront of additive manufacturing, B9Creations’ professional 3D printing solutions serve a variety of high-precision applications in nearly 70 countries around the world, serving brands ranging from Medtronic to Johnson & Johnson, B. Braun Medical Inc., Mayo and the National Institutes of Health, with a track record of rapid innovation in the healthcare sector.

Leveraging patented technology and high-speed contactless printing, B9Creations’ 3D printers are manufactured to the tightest tolerances in the industry, out of the box and printing in 15 minutes, four times faster than industry average, and never require calibration.

As engineers with backgrounds ranging from missile systems to medical devices, B9Creations’ deep expertise in precision 3D printing, quality control, and regulatory requirements has served customers requiring the highest levels of quality and reliability.

B9[x] Custom Solutions

Through the B9[X] Division, B9Creations’ robust technological capabilities — across hardware, software, materials, and services — equips customers with customized 3D printing solutions that fit their unique business needs.

B9Creations enables its customers to take an application-smart approach with workflows customized by industry, workforce expertise built into software, custom hardware, and materials designed around specific parts, production, and regulatory compliance.

On-Demand Anatomical Models, Surgical Tools, Custom Medical Devices, and More

To help with the broader integration of additive technology into the medical field, B9Creations’ Healthcare Division also offers 3D printing services in a diverse portfolio of medical applications to equip partners to support patient-customized surgical planning and tools, create better educational models, and bring revolutionary devices to market faster than ever before.

About B9Creations

As a global provider of professional 3D printing solutions, B9Creations has become the industry leader in production, speed and value. It now stands as the additive manufacturing market leader in high-precision applications such as medical, jewelry, prototyping and manufacturing, research and model making. B9Creations serves customers and certified dealers in nearly 70 countries around the globe. Find us online at b9c.com, on Facebook, Twitter, Instagram, YouTube and LinkedIn.