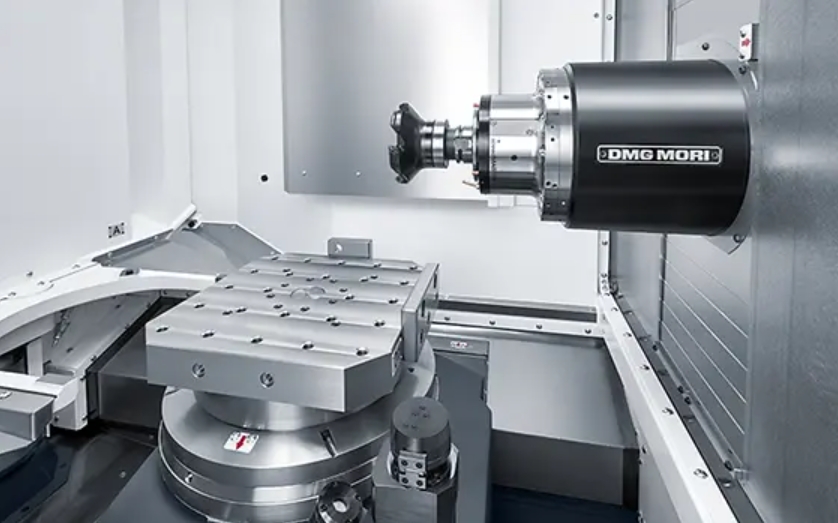

TOKYO, Japan, Dec 2, 2025 – DMG MORI CO., LTD. (hereinafter referred to as “DMG MORI”) has launched the newest generation of horizontal machining centers: NHX 4000 / 5000 4th Generation (“NHX 4th Generation”). With increased spindle output and feed rates, the NHX 4th Generation delivers shorter cycle times, reduced energy consumption through integrated coolant and inverter control, and minimized maintenance workload thanks to advanced chip management for fast, stable, and cost-efficient high-precision machining.

The NHX Series is trusted for high-efficiency mass production in industries requiring high rigidity and accuracy, including aerospace, EV, semiconductors, construction machinery, and mold manufacturing. The NHX 4th Generation builds on this foundation to deliver even greater productivity and machining efficiency.

Customers can reduce cycle times with the speedMASTER spindle at 400 V with up to 50% more output and rapid traverse speeds of 70 m/min. For stable automation, DMG MORI offers dedicated solutions for chip, coolant, and mist management. The zero-sludgeCOOLANT pro*1 system with its high-capacity vertical coolant tank enables continued unmanned operation while minimizing maintenance work.

In addition, the new ERGOline X control panel combines a wide screen touch panel with hardware buttons into an intuitive interface. The integrated CELOS X software supports the latest applications, driving digital transformation (DX) on the shop floor.

The NHX 4th Generation supports sustainable manufacturing by improving overall production efficiency. Energy consumption of peripherals is reduced through integrated coolant pumps, inverter control, and valve optimization. For example, taking the production of 32 control valves per day, customers can increase machine utilization by approx. 10% and reduce power consumption and CO₂ emissions by around 30% (saving about 2,078 kilograms of CO₂ annually) only by replacing the NHX 5000 3rd Generation with the new NHX 5000 4th Generation.

With the NHX 4th Generation, customers can realize both stable and sustainable production. Additional models including NHX 5500 / 6300 / 8000 4th Generation are currently in development. For more details, please refer to the videos and catalogs available on our official website.

Main features

1. Up to 15%*4 shorter cycle times compared to previous models

- High-speed/high-torque speedMASTER spindle with 400 V for 50% higher output Standard spindle with max. 20,000 min-1 rpm for 50%*4 higher material removal during high-speed aluminum machining

- X/Y/Z-axis rapid traverse speed increase from 60 m/min to 70 m/min Optimized acceleration control to reduce non-cutting time for short distances

- CELOS Chatter Control*1 for automatic chatter detection

and one-touch parameter changes on NC programs

2. Intuitive interface design

- Rotable ERGOline X H2M interface for improved operability

and easy workpiece & spindle access - Standard 60-tool ring magazine for fast indexing

Optional ring, chain, and rack type magazines for up to 300 tools - Standard magazine operation panel supports all tool setup related operations

3. Flexible automation solutions*1

- Wide range of pallet handling systems

RPS (Rotary Pallet Storage) system

Workpiece setup in a compact footprint with high pallet density

CPP (Compact Pallet Pool) system

8 different scalable options for easy introduction

LPP (Linear Pallet Pool) system

Fully customizable multi-level pallet racks for maximum productivity - MATRIS: modular robot system for optimal customization

- CTS (Central Tool storage): high-capacity storage for integrated tool & process management

4. Reduced cleaning & maintenance work

- Solutions for chips, coolant, and mist management

Stainless steel covers to prevent chip accumulation

Dual-axis motorized nozzles*1 for efficient cleaning

and AI chip removal*1 to prevent chip accumulationChip conveyor capacity x3 for smooth discharge

Standard zero-sludgeCOOLANT for fine sludge filtration

Optional zero-sludgeCOOLANT pro*1 for long periods of continuous operation

Mist collection by zeroFOG*1 - Frequent maintenance areas designed for easy operator access

5. 30%*4 less power consumption and CO₂ emissions

- Single high-efficiency pump with inverter control for energy savings

- In-house developed transformer & GREENmode for sustainable production

- SBT-certified*5 for CO₂ reduction across the whole supply chain

About DMG MORI

DMG MORI is a worldwide leading manufacturer of high-precision machine tools and sustainable technologies that are at the heart of global value chains. In the “Global One Company” more than 12,000 employees are in direct contact with over 100,000 customers from 57 industries. DMG MORI is globally present in 88 countries with 16 production plants, 113 sales and service locations.

Integrated automation and end-to-end digitization solutions expand the core business with lathes and milling machines, ultrasonic, lasertec and additive manufacturing. The entire manufacturing know-how from more than 152 years flows into technology excellence for the focus industries Aerospace, Automotive, Die & Mold, Medical and Semiconductor. Customer-oriented services accompany the entire life cycle of a machine tool – including training, repair, maintenance and spare parts service. The strategic fit of automation, digitization and sustainability fits perfectly with DMG MORI’s vision and mission statement: We empower our customers in manufacturing and digitization! We want to be the most attractive machine tool manufacturer worldwide with digital and sustainable products!