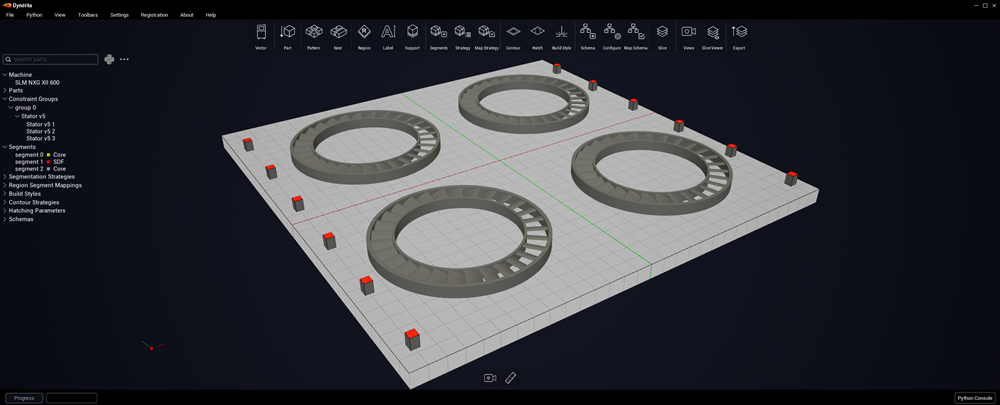

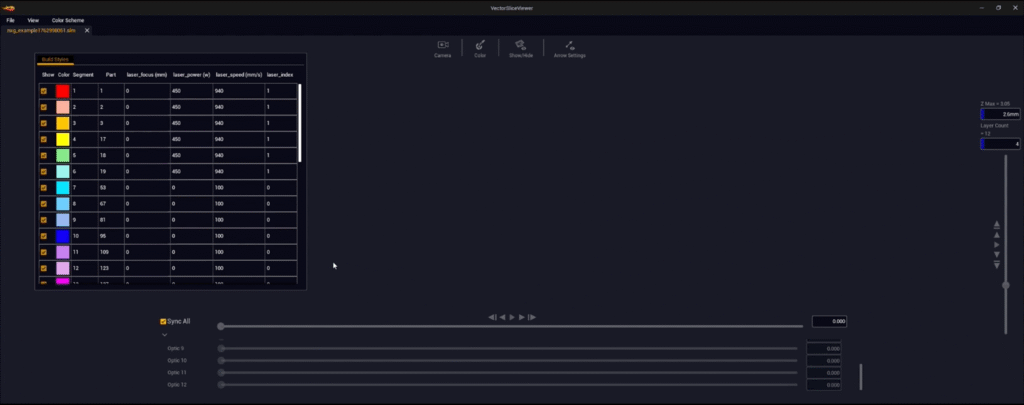

SEATTLE, WA, USA, Nov 14, 2025 — Dyndrite, providers of next generation industrial software for additive manufacturing, today announced enhancements to Dyndrite LPBF Pro with an NXG Slice Viewer, a fully time-simulated, 12-laser toolpath visualization and debug environment purpose-built for Nikon SLM Solutions’ NXG Series of large-format multi-optic metal additive manufacturing machines, including the NXG XII 600 and NXG 600E. Developed in support of Nikon SLM’s open architecture, and refined with extensive feedback from early customers, the LPBF Pro NXG Slice Viewer gives machine users unparalleled visibility into multi-laser behavior during builds with tools to debug custom optic allocation strategies.

“High-throughput, 12-laser platforms demand tailored software,” said Steve Walton, Head of Product, Dyndrite. “Our NXG Slice Viewer shows every laser parameter, every vector, every timing event, concurrently and in sequence, so users can spot issues, improve optic allocation, and develop advanced scan strategies to maximize machine productivity. It’s the must-have tool for NXG users who are scaling to real production.”

Built for NXG Production

- True time simulation of all 12 lasers at once – Play, pause, scrub, and step through layers with custom jump delay, mark delay, and more.

- Enhanced UI – View lasers individually or synced, leverage high color contrast modes, control thickness, and more.

- Optic allocation intelligence – Fully connected to Dyndrite’s custom optic-allocation tools for NXG Series, enabling rapid what-if analysis to balance utilization, reduce idling, minimize cross-talk, and dynamic forced laser synchronization

- Early-user hardened – Shaped by hands-on feedback from alpha/beta customers operating NXGs.

“Dyndrite is what metal AM software should have been decades ago. With the fast iteration and collaboration provided by the Dyndrite team we are receiving specialized tools for operating our NXG and enabling maximum utilization of our assets.” — Representative from an Aerospace Company Operating an NXG.

“Every interaction with the Dyndrite team brings forward something new that directly improves how we operate. As a multi-NXG owner, control and predictability are critical to our production strategy. On large-format multi laser machines like these, every millisecond of laser on time matters. Our goal is maximum throughput, and the Dyndrite NXG Slice Viewer is helping us get there. We’re continuing to collaborate closely with Dyndrite to enable customized optic allocation strategies that further enhance efficiency and part quality across our NXG fleet.” — Manufacturer Operating Multiple NXG Systems.

“At Nikon SLM Solutions, we believe that an open architecture is the key to accelerating innovation in additive manufacturing,” said Brent Stucker, Chief Engineer at Nikon SLM Solutions. “Dyndrite’s new NXG Slice Viewer is a perfect example of that philosophy in action. By leveraging the openness of our NXG Series, Dyndrite has delivered a powerful visualization tool that gives customers deep insight and control over their multi-laser production processes. We’re proud to see partners like Dyndrite using our open architecture to enhance the NXG ecosystem and help our shared customers achieve higher printing confidence.”

Availability

The NXG Slice Viewer is available today as part of the latest Dyndrite LPBF Pro release. Existing LPBF Pro NXG customers can access the feature immediately.

Dyndrite Hands-On Workshop – “You control the laser” – Nov 17th – Frankfurt, Germany.

Get hands-on with Dyndrite LPBF Pro! Join the Dyndrite 2025 You Control the Laser World Tour, the day before Formnext. Experience Dyndrite LPBF Pro in action and learn how to unlock scalability in your metal AM operations. Register here.

About Dyndrite

Dyndrite’s mission is to fundamentally change how geometry is created, transformed and transmitted on a computer. Our Accelerated Computation Engine (ACE) is the world’s first (geometry agnostic), multi-threaded, GPU-accelerated geometry engine. We create and license tools that give companies the power, freedom and control necessary to deliver on the potential of digital manufacturing.

Investors include Gradient Ventures, Google’s AI-focused Investment Fund and former Autodesk CEO Carl Bass. The company was founded in 2015 and is headquartered in Seattle, WA. Dyndrite was named a World Economic Forum Technology Pioneer for 2021. For more information visit: www.dyndrite.com.

About Nikon SLM Solutions

Nikon SLM Solutions AG is a global provider of integrated metal additive manufacturing solutions. Leading the industry since its inception, it continues to drive the future of metal AM in every major industry with its customers’ long-term success at its core. Nikon SLM Solutions is home to the world’s fastest metal additive manufacturing machines boasting up to 12 lasers and enabling build rates of up to 1000ccm/h. With a portfolio of systems to suit every customer’s needs, along with its team of experts closely collaborating at every stage of the process, Nikon SLM Solutions leads the way on return on investment with maximum efficiency, productivity, and profitability. Nikon SLM Solutions believes that additive manufacturing is the future of manufacturing and has the desire and capability to take its customers there – right now.

Nikon SLM Solutions AG is a Company headquartered in Germany, with offices in Canada, France, India, Italy, Singapore, South Korea, and the United States.Further information is available on www.nikon-slm-solutions.com.