LOS ANGELES, CA, USA, Jun 27, 2024 – RAPID + TCT – Dyndrite, providers of the GPU-accelerated computation engine used to create next-generation digital manufacturing hardware and software, announced an updated release of Dyndrite LPBF Pro, the company’s 3D printing software for Laser Powder Bed Fusion (LPBF) machines, including Aconity3D, EOS, Nikon SLM Solutions, Renishaw and Xact Metal.

Dyndrite LPBF Pro is a GPU-powered software toolkit that provides metal AM manufacturers with previously unattainable capabilities, including the ability to print previously impossible parts, define accelerated build strategies, and automate their build preparation. The software is designed to enhance the productivity, precision, traceability, and repeatability of AM materials development and serial production processes, while managing the increasing data demands of additive manufacturing. The software sets a new standard in the development of new materials, alloys, and multi-materials parameter sets, has the ability to work with multiple layer heights, enables the printing of intricate geometry, including small features, thin walls, domes, and cantilevers, provides extensive surface roughness controls, and offers methods for developing support-free print strategies. Dyndrite LPBF Pro is used within the aerospace, defense, rocketry, automotive, energy, and medical industries.

Enhanced Functionality

• Support Geometry- More control over part and build plate interfaces for supports, including APIs for part avoidance and connection.

•Toolpath – Advanced tools for heat exchangers/thin walls, beam stirring, and multi-optic strategies all have expanded apis, along with best-in-class build time estimations.

• Trajectory – New APIs with examples addressing multi-laser constraints.

• Integrated learning – Applicable for all experience levels, Dyndrite LPBF Pro presents a novel integrated documentation and scripting interface that educates users as they interact with the product. Customers report quick adoption across varied user experience levels.

“Over the past six months, we’ve collaborated closely with the members of our Early Adopter Program to ensure our toolkit addresses their most significant technical challenges and process control needs,” said Steve Walton, Head of Development for Dyndrite. “Their feedback has been invaluable, and is incorporated in this latest release. We are excited to see what our users will be able to accomplish with these new tools.”

Enhanced Renishaw Support

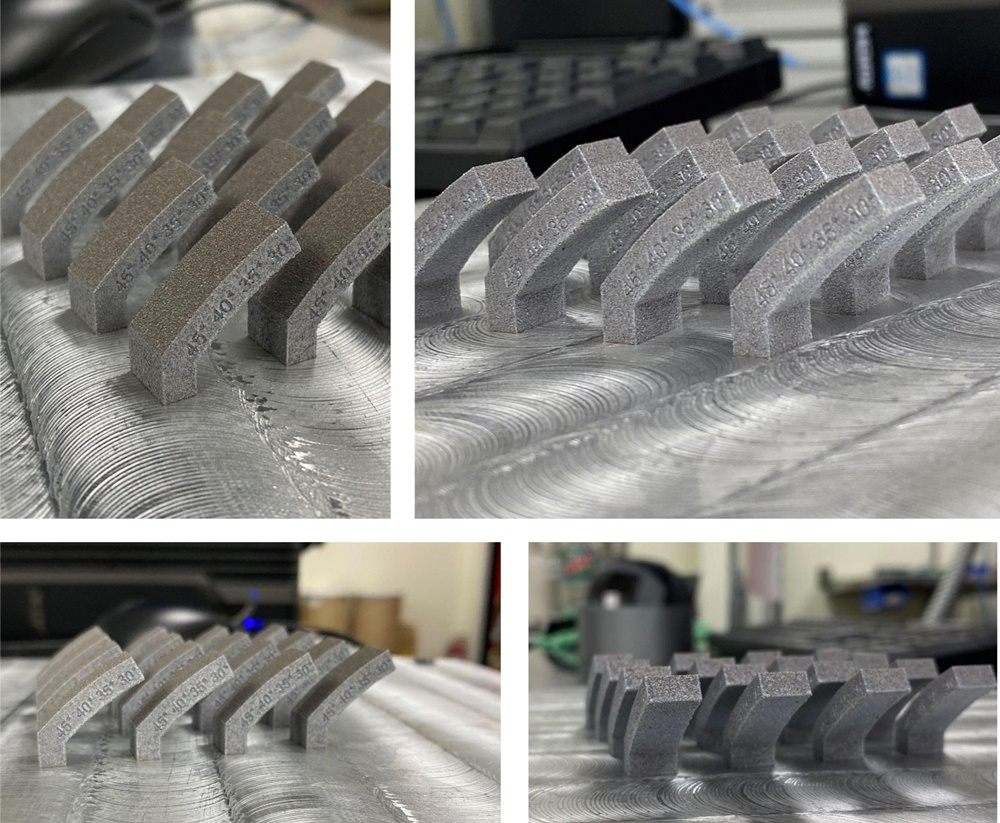

Renishaw QuantAM users can now leverage Dyndrite LPBF Pro’s 3D Volumetric Segmentation tools to analyze and assign multiple parameters to a part. Using this method Renishaw users were able to successfully print coupons with overhangs down to 30° support-free. See Image below:

“Dyndrite has shown an incredible level of commitment to our industry with the release of Dyndrite LPBF Pro product, said Kevin Brigden Application Engineering Manager, Renishaw Inc. “The leveraging of Renishaw’s QuantAM API ensures that our current and future customers have the opportunity to easily explore the incredibly powerful tool sets offered by Dyndrite. I’m extremely keen to see the novel solutions developed with volumetric segmentation and the increased performance gained with Dyndrite’s powerful tool path customization capabilities.”

NEW: Representative Parts on Display at Rapid+TCT 2024 in Los Angeles

During the Rapid + TCT 2024 conference, a number of companies will showcase Dyndrite LPBF Pro printed parts. Each highlights the combined value of their material, or expertise with Dyndrite’s print performance and flexibility, these include:

• Equisphere (booth 1361) – Showcasing customer aluminum parts printed both without, and with Dyndrite LPBF Pro demonstrating high-productivity and surface finish control.

• Dyndrite (booth 2031):

- AMS – will showcase parts printed using a jointly developed “Continuous Offset Contour” approach that overcomes the over-energized zones that legacy vector path and hatching strategies typically create, which often leads to peeling or build failures during the production of motorsport parts featuring thin wall ducts.

- Aconity3D – Is presenting Equispheres aluminum prints demonstrating the high-productivity and advanced surface quality capabilities of Equispheres, Dyndrite LPBF Pro, and Aconity3D

- Additional qualification builds printed on Nikon SLM, Renishaw, & EOS machines

About Dyndrite

Dyndrite’s mission is to fundamentally change how geometry is created, transformed and transmitted on a computer. Our Accelerated Computation Engine (ACE) is the world’s first (geometry agnostic), multi-threaded, GPU-accelerated Geometry Engine. We create and license tools that give companies the power, freedom and control necessary to deliver on the potential of digital manufacturing.

Dyndrite LPBF Pro, a powerful software solution designed to enhance the capabilities of Laser Powder Bed Fusion (LPBF) for metal 3D printing. It provides users with previously unattainable part printing capabilities, accelerated build rates, and unprecedented productivity. Dyndrite LPBF Pro is compatible with a wide range of metal 3D printing machines, including brands such as Aconity3D, EOS, Renishaw, NikonSLM, among others.

Investors include Gradient Ventures, Google’s AI-focused Investment Fund and former Autodesk CEO Carl Bass. The company was founded in 2015 and is headquartered in Seattle, WA. Dyndrite was named a World Economic Forum Technology Pioneer for 2021.

For more information visit: www.dyndrite.com.