KRAILLING, Germany, May 1, 2024 – EOS, a global leader of additive manufacturing (AM) technologies, services and materials, announced the addition of its EOS Aluminium AlSi10Mg to its Responsible Products portfolio alongside the launch of VIRTUCYCLE – its global used polymer material take-back program to reduce material waste. As one of the largest AM original equipment manufacturers (OEMs) in the world, EOS is committed to minimizing the climate impact of manufacturing, and today’s announcement expands on that commitment.

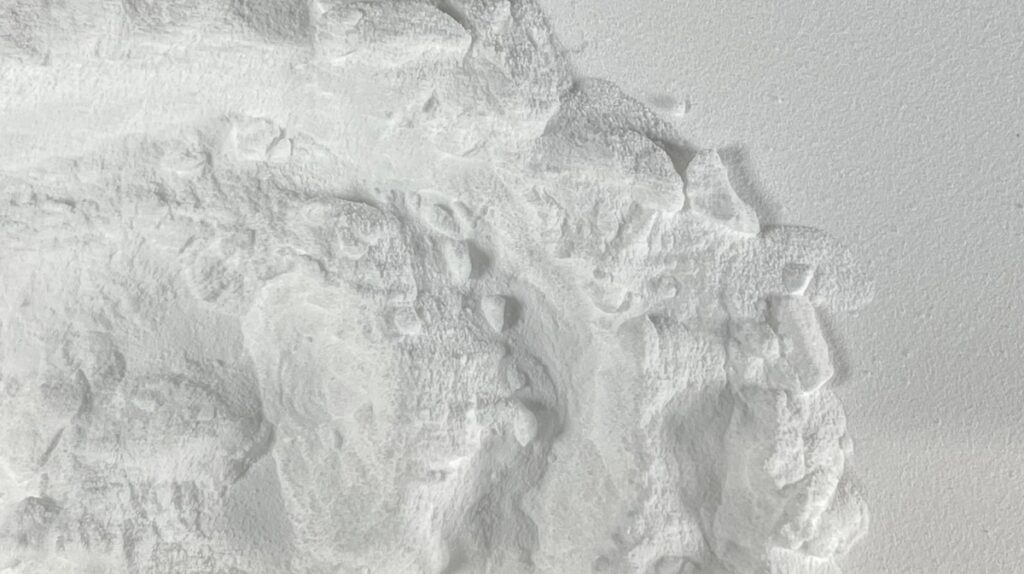

Responsible EOS Aluminium AlSi10Mg

EOS Aluminium AlSi10Mg is one of the most popular products in its portfolio and now incorporates a minimum of 30% recycled feedstock achieving a 25% CO2e reduction compared to the prior formulation. Additionally, the new formulation maintains the same properties, characteristics, and performance in additively manufactured parts, helping ensure existing EOS Aluminium AlSi10Mg customers do not need to requalify applications. Specifications for EOS Aluminium AlSi10Mg remain unchanged:

- Chemical composition standard: AlSi10Mg

- Ultimate tensile strength: 460 MPa

- Yield strength: 245 MPa

- Elongation at break: 5%

- Good thermal and electrical conductivity with possibility of heat treatment

“Our commitment to offering responsible products that support AM production is growing to include our metal materials. We are striving to create carbon footprint transparency for our premium metal materials. These externally verified numbers are also providing transparency to our customers by including these materials in our Carbon Calculator, furthering sustainability initiatives for both our customers and for EOS.” Sophia Heyl, product specialist, metal materials at EOS.

VIRTUCYCLE Used Polymer Material Take-Back Program Now Available

EOS has also partnered with Agiplast, an Arkema company, to offer its new VIRTUCYCLE program. VIRTUCYCLE takes used polymer material and components, using 100% sustainably sourced energy to transform AM powder into recycled high-performance injection molding granules. To verify the positive impact of this circular economy program, EOS performed a life cycle analysis, externally verified by TÜV Süd, confirming 1kg of polymer material turned into 0.945 kg* granules, saves approximately 7kg CO2e in comparison to raw material.

EOS is continuously identifying and reducing CO2e emissions throughout its supply chain, expanding the responsible mindset to encompass all areas of its business. Additional EOS Responsible Products currently available include:

- PA 1101 ClimateNeutral with 100% proven quality and zero CO2e, ClimateNeutral materials are biobased products where all remaining GHG emissions are offset with Gold Standard carbon credits.

- PA 2200 CarbonReduced materials and products where GHG emissions are reduced significantly by suitable measures such as green energy in the production process.

- Carbon Calculator considers AM project carbon emissions with key cost metrics to provide an estimation of the organization’s AM CO2e and expenses.

“I am delighted that we are continuing our way towards Responsible Manufacturing and expanding our portfolio of Responsible Products stepwise. By minimizing waste, reducing the environmental footprint and prioritizing eco-friendly materials, organizations can both protect our planet and create a more efficient and resilient business model.” Björn Hannappel, head of sustainability at EOS.

*Difference stemming from losses in the process.

About EOS

EOS provides responsible manufacturing solutions via industrial 3D printing technologies to organizations around the world. Since 1989, EOS has shaped the future of manufacturing by enabling its customers to innovate and differentiate through expert guidance, technology and services, leveraging its end-to-end additive manufacturing (AM) industry partnerships. From strategy to education to production, EOS is the leading global partner for both metal and polymer AM solutions, accelerating time-to-market for its customers through high-quality production efficiencies and sustainable solutions. For more information, visit https://www.eos.info.