STUTTGART and COBURG, Germany, Nov 14, 2025 – Farsoon Europe GmbH has teamed up with Brose to develop a metal 3D printer tailored to the high demands of the automotive industry. One outstanding feature of this innovative printer is its compatibility with sustainable metal powder. It is made entirely from recycled steel waste from Brose’s own press shops. The high-performance 3D printer helps Brose meet strict CO2 targets without compromising on quality and performance.

The newly developed metal 3D printer is based on the FS721M-8-CAMS system with a build volume of 720 x 420 x 390 mm³. Farsoon also offers the system with an optional build volume height of 650 mm. Farsoon designed the system for Brose with eight lasers – ideal for efficient component production. At 8 x 2000 watts, the laser power is well above the market standard. This combination enables Brose to achieve significantly more efficient additive series production.

A very unique feature is Farsoon’s patented special ‘beam shaping’ technology. The use of beam shaping technology enables efficient and profitable utilization of the high laser power. Beam shaping works with larger laser spot diameters in the form of a circular ring, which, among other things, results in a very homogeneous melt pool and ultimately high-quality components.

Another highlight is the advanced CAMS technology (Continuous Additive Manufacturing System). This allows the finished print job to be removed from the machine immediately after printing. A new build container is then inserted into the machine. This ensures that laser downtime, during which no work can be done, is minimized.

In addition to the hardware, the software has also been further optimised in terms of the simple and fast handling of many components in a single job.

All these measures together make the system a highly efficient printer that achieves the lowest possible component costs.

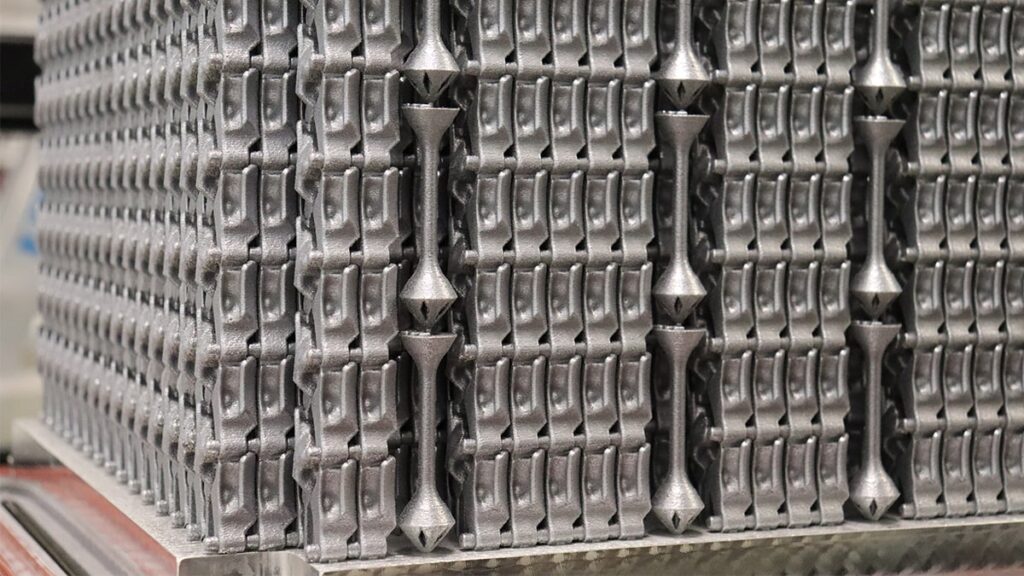

Fig. 2 shows a construction job printed on the Farsoon FS721M-8-CAMS with high packing density. The construction job contains more than 21,000 components, which are manufactured without support structures. During component design, care was taken to ensure that component post-processing could be carried out fully automatically without manual processes.

If you have any questions, please visit us at this year’s Formnext in Frankfurt/Main in Hall 11.0, Stand E11. The central trade fair for industrial 3D printing will take place from 18 to 21 November in Frankfurt am Main.

“The advanced system supplied by Farsoon enables us to profitably produce larger series thanks to higher throughput and shorter production times. With the FS721-8-CAMS, Brose can now produce more components per production order, shorten cycle times and increase overall profitability – making additive manufacturing an economical solution for high-volume applications,” explains Eric Fritzsche, Head of Additive Manufacturing. “An outstanding feature of the innovative 3D printer is its compatibility with ‘Green Steel’, a low-alloy steel material that supports our commitment to sustainable production.”

“Together with Brose, we turned innovation into real production efficiency — a great example of what strong partnership and open technology can achieve,” said Oliver Li, Managing Director of Farsoon Europe. “The combination of material, component design and perfectly matched printers thus represents a very valuable milestone for the future.”

About Brose

Brose is the largest privately owned German company in the automotive supply industry. Every third new car is equipped with at least one Brose product. The mechatronics specialist develops and manufactures systems for vehicle doors, flaps and seats. Brose also produces electric motors ranging from 200 watts to 14 kilowatts for various applications such as steering, thermal management and e-scooters. The family-owned company employs around 31,000 people at 68 locations in 24 countries. In 2024, the Brose Group generated sales of 7.7 billion euros. For more information, visit https://www.brose.com.

About Farsoon

FARSOON Technologies, founded in 2009, is a system supplier of industrial plastic and metal AM platforms. With an open parameter strategy, high-performance hardware and localized support via FARSOON Europe GmbH, the company empowers customers to scale additive manufacturing with quality, flexibility and cost efficiency. For more information, visit https://www.farsoon-gl.com.