FRANKFURT, Germany, Jun 26, 2025 – Farsoon, a leader in additive manufacturing innovation, is pleased to announce the launch of large-scale, production-grade copper alloy additive manufacturing solution, FS621M-Cu.

Copper and copper alloys are prized in aerospace engine combustion chambers for their outstanding electrical and thermal conductivity, corrosion resistance, and ductility. Yet their high reflectivity to near-infrared lasers (particularly at 1064 nm) has long hindered their adoption in metal 3D printing.

Farsoon was among the first to become one of China’s first companies to master copper alloy printing by developing a copper-compatible process on its FS271M metal platform in 2017.

Building on this expertise, Farsoon partnered with a leading aerospace manufacturer in 2023 to co-develop the large-format additive manufacturing solution designed for copper alloys. Based on the proven large-format metal AM system FS621M platform (build envelope 620mm x 620mm x 1100mm), the new FS621M-Cu system integrates four 1000W ytterbium fiber lasers (1060–1080 nm) to achieve stable, long-duration printing of highly reflective materials like CuCrZr, enabling the production of large, complex aerospace components previously deemed unfeasible.

Revolutionizing Thrust Chamber Production

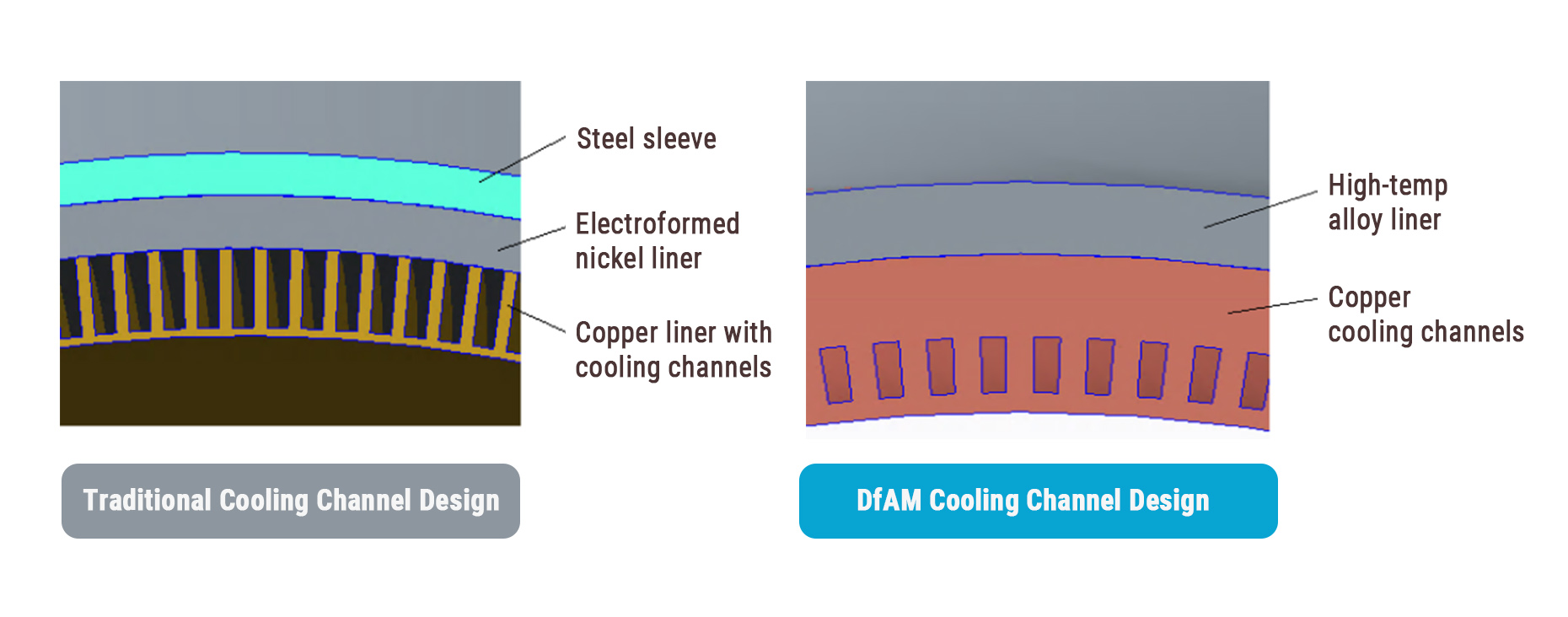

The thrust chamber, a liquid rocket engine’s most critical—and notoriously difficult—component, must withstand extreme temperatures, pressures, and vibrations while maintaining precise regenerative cooling channels. Traditional manufacturing relies on labor-intensive processes like spinning, machining, and brazing that incur high costs and extended lead times.

Farsoon’s FS621M-Cu platform leverages laser powder bed fusion (LPBF) to monolithically print copper alloy thrust chamber liners with optimized cooling channels. This approach eliminates assembly steps, enhances heat transfer efficiency, and improves engine performance—all while reducing production costs and slashing development cycles.

Engineering Breakthroughs for High-Reflectivity Materials

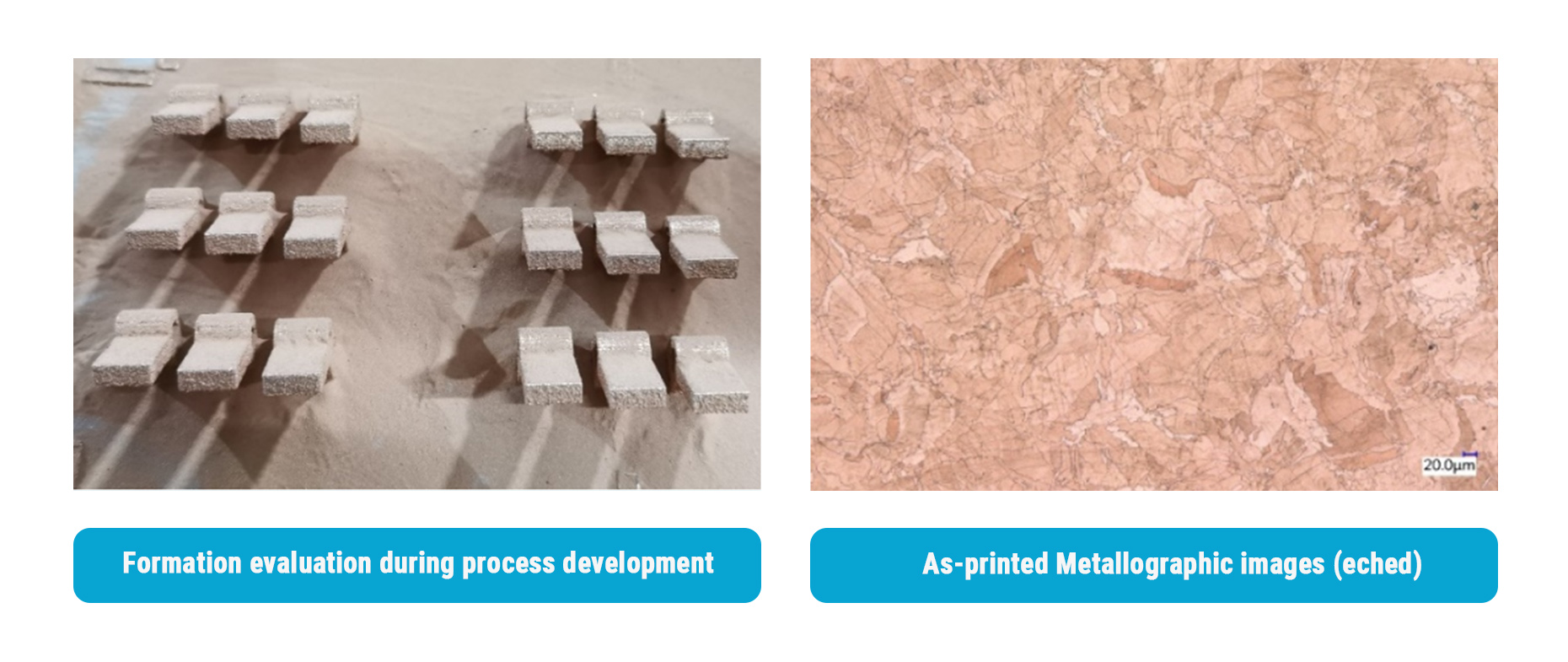

Copper’s high thermal conductivity and laser reflectivity pose unique challenges in AM, often leading to defects like porosity, delamination, and warping. Farsoon overcomes these hurdles through a suite of innovations: an anti-reflective chamber coating, a smart thermal management system, and high-power 1000W lasers paired with tailored process parameters.

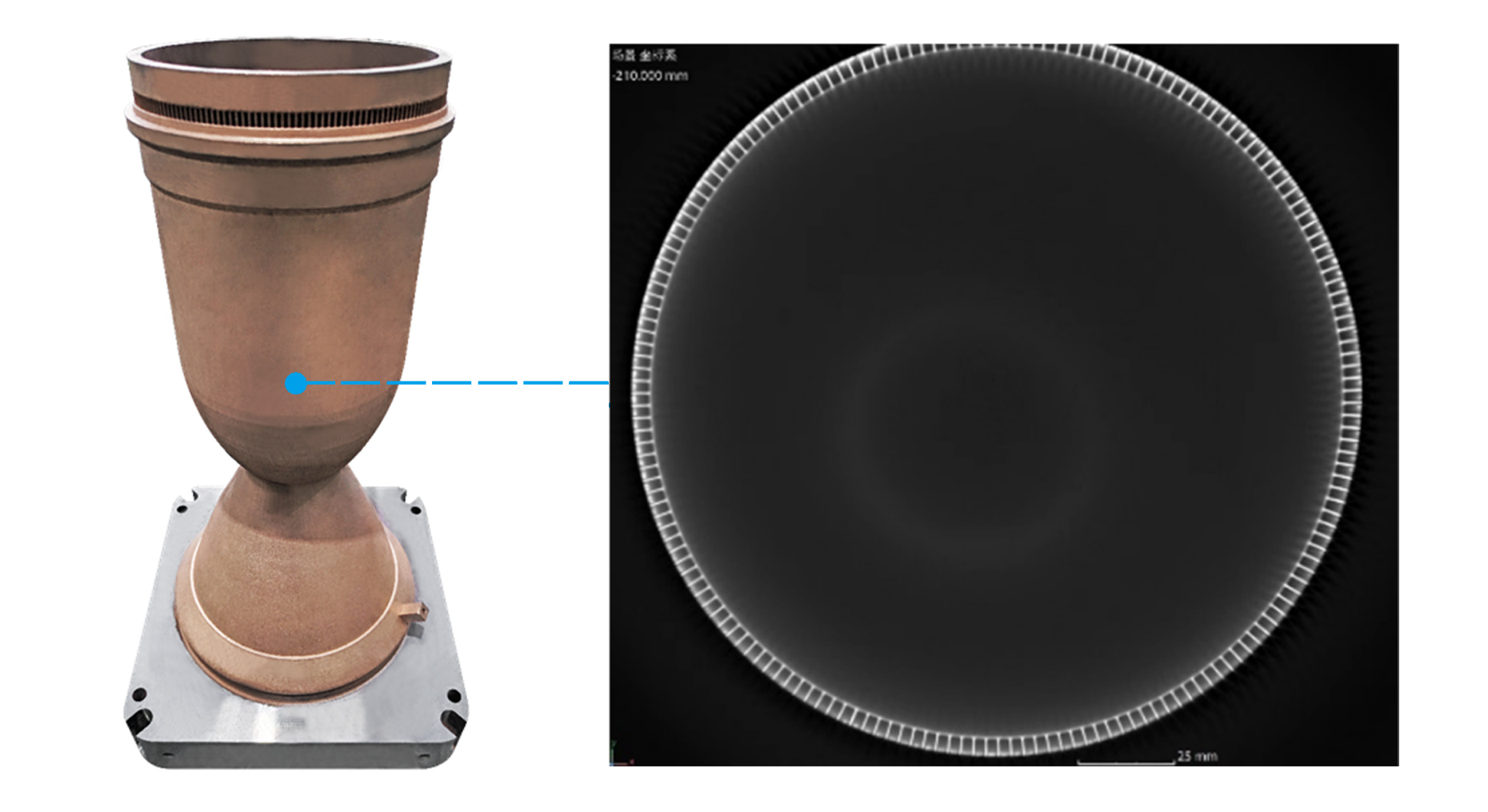

The results speak for themselves. In August 2023, the aerospace customer used the FS621M-Cu platform to produce a 600 mm diameter × 850 mm height thrust chamber liner—one of the largest monolithic copper alloy components ever 3D printed. Testing confirmed exceptional material properties: near-theoretical density (8.86 g/cm³), a pore-free microstructure, and thermal conductivity exceeding 345 W/(m·K). X-ray scans further validated the precision of internal cooling channels, which were polished post-build to minimize pressure drop and maximize engine efficiency.

Performance Validation & Process Breakthroughs

Mechanical testing of as-printed tensile specimens demonstrated excellent comprehensive properties. Thermal characterization revealed outstanding results:

• Thermal conductivity: ≥345 W/(m·K)

• Thermal diffusivity: ≥95 mm²/s

• Specific heat capacity: ≥0.35 J/(g·K)

Through systematic development in 2023, including copper alloy powder quality control and LPBF process optimization, the customer achieved a technological breakthrough in CuCrZr laser additive manufacturing. The resulting components exceeded design specifications by >50% while achieving:

• Significant improvement in dimensional accuracy

• Dramatically reduced lead time (15-20 days vs traditional methods)

• Substantial cost reductions (up to 75%)

As demand for high-performance copper components surges, Farsoon delivers the large-scale, stable printing capabilities aerospace innovators need. For more information, contact Farsoon at globalinfo@farsoon.com.

About Farsoon

FARSOON Technologies, founded in 2009 in China, is a system supplier of industrial grade plastic laser sintering and metal laser melting systems. Farsoon has developed a team of world-class experts with competencies in electrical/mechanical engineering, laser, scanning and optics, thermal controls, as well as material development and applications engineering. As a globally diverse company, Farsoon was founded with the clear vision and core commitment to creating open platform systems which will give the industry the freedom to innovate and expand the implementation of additive manufacturing in the global product’s marketplace.

Farsoon’s subsidiary FARSOON Europe GmbH (Stuttgart, Germany) provides the whole range of machine portfolio after technical confirmation in China, as well as local service and maintenance activities. For more information, visit https://www.farsoon-gl.com.