Guest Post by BEACON India – Formlabs Re-seller India

Form 4 represents the next evolution in SLA 3D printing, built upon years of groundbreaking hardware, software, and materials science innovations. With unprecedented speed, Form 4 delivers the majority of parts in under two hours, in all materials, without ever compromising on dimensional accuracy or surface finish.

Stunning Parts: Rivaling injection molded parts.

Blazing Fast: Most prints in under 2 hours

Versatile: Industry-leading materials for any problem

Intuitive: Anyone can learn in 15 minutes

Reliable: Unmatched print success rate

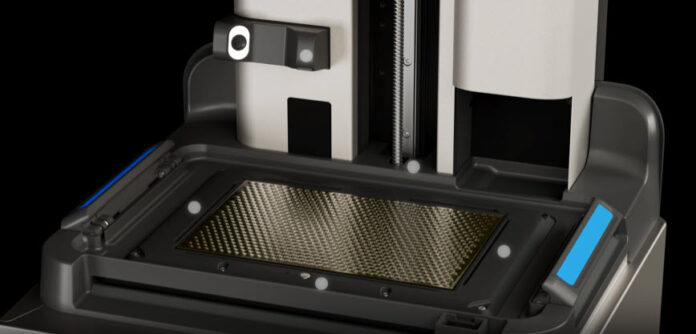

Explore the Hardware of the Formlabs Form 4 or 4B Printer:

- Backlight

The Backlight Unit generates a uniform area projection of an ultra-high power light using 60 LEDs and collimating lenses. It cures resin quickly and precisely, delivering blazing fast print speeds with excellent print quality and accuracy anywhere on the build platform.

- Light Processing Unit

The Light Processing Unit 4 (LPU 4) precisely masks light from the backlight unit into the shape of a printed layer. Together, the Backlight Unit and LPU 4 enable you to print with extreme speed, accuracy, and print quality anywhere on the build platform. The LPU 4 is long -lasting, resistant to accidental damage, and easy to replace.

- Release Texture

A proprietary, microtextured optical film provides airflow between the resin tank and the Light Processing Unit. This film is built into the Light Processing Unit and sits at the top of it. This significantly reduces peel forces so you can print at blazing fast speeds without sacrificing surface finish, fine features, accuracy, or reliability.

- Intelligent Control Systems

Six onboard control systems precisely measure and maintain the temperature, resin level, print forces, and print status inside your printer. Together, they ensure consistent, reliable performance and prevent common failures, for the same results on every printer and every print.

- Resin Tank

The Form 4 Resin Tank holds liquid resin inside the printer and provides a substrate for the liquid resin to cure against, using a dual-layer flexible film stack. It significantly reduces peel forces so you can print at blazing fast speeds without sacrificing surface finish, fine features, accuracy, or reliability.

- Automatic Resin Handling

Integrated system that dispenses resin quickly, accurately, and with minimal waste, while making it easy to switch materials. Print without having to worry about your printer running out of resin and switch materials in <1 minute. Form 4 is still one of the only SLA printers on the market to offer this feature.

We hope you found it informative and inspiring. Stay tuned for future updates, and don’t hesitate to reach out with any questions or feedback.

Happy Printing!

Guest Post by BEACON India – Formlabs Re-seller India