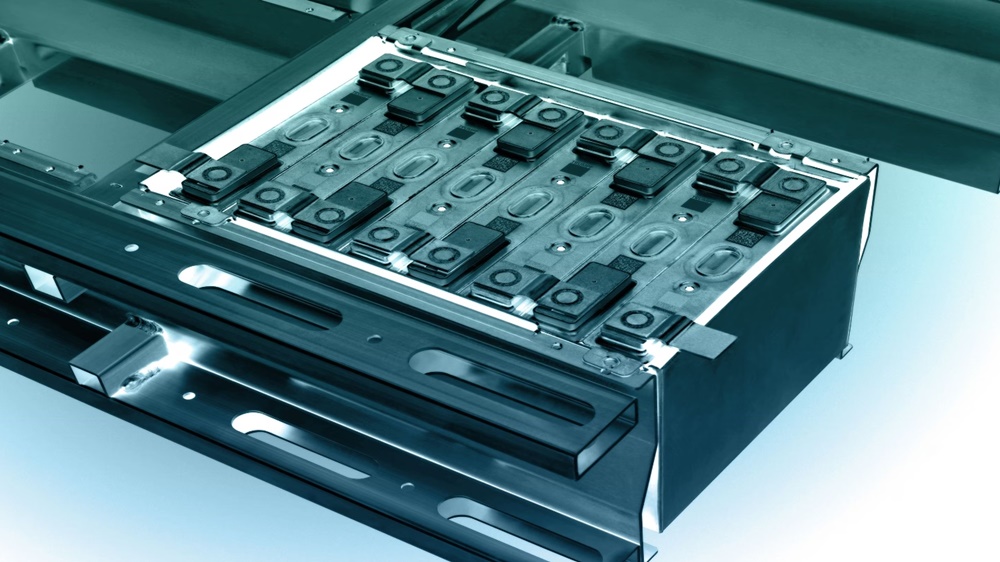

DITZINGEN, Germany, Mar 4, 2024 – In the future, manufacturers of electric car batteries could further improve the durability and performance of electric car batteries with compact X-ray sources. The XProLas development partnership has now started to develop these laser-driven X-ray sources under the leadership of TRUMPF. The first demo systems are to be built by 2026. In future, manufacturers will be able to use these systems to monitor the charging and discharging of batteries in real time or determine impurities in the battery with particular precision. The findings will be incorporated into the development of new batteries. With the conclusions drawn from the analyses, manufacturers will be able to improve, for example, the charging speed. Until now, companies have only been able to carry out such investigations on large particle accelerators over 100 metres long. Research stations at these large-scale research facilities are rare. The laser-driven X-ray sources are only about the size of a mobile home and as such are cheaper to manufacture. They are therefore ideal for use in industry.

The high-tech company TRUMPF is contributing its expertise in the manufacture of lasers for industrial use to the partnership. BASF and Cellforce are providing battery materials and components for the tests. Ushio Germany and Excillum are contributing their expertise in the field of beam sources. Bruker and Viscom are responsible for the construction of the systems. On the academic side, the University of Hanover and the Fraunhofer Institutes in Aachen and Jena are the driving forces. The research budget amounts to around 15 million euros and the Federal Ministry of Education and Research (BMBF) is funding the project.

X-rays for better batteries in electric cars

The XProLas development project also aims to create a compact, high-brilliance X-ray source for analyzing the cathode material of electric car batteries. The material from which the cathodes of electric car batteries are made is of central importance for the performance and reliability of electric vehicle batteries. The exact composition of the cathode material can only be determined using X-rays. The compact, laser-driven variants can also replace large-scale research facilities in this field of application. Manufacturers of cathode material can thus speed up their development work.

The laser serves as a so-called upstream beam source in the generation of X-rays. The laser pulse hits the so-called target, a metal such as gallium, indium or tin. A plasma is created; this plasma emits some of the energy as extremely short-wave light, for example X-rays.

About TRUMPF

TRUMPF is a high-tech company offering manufacturing solutions in the fields of machine tools and laser technology. The Company drives digital connectivity in the manufacturing through consulting, platform products and software. TRUMPF is one of the technology and market leader in highly versatile machine tools for sheet metal processing and in the field of industrial lasers. In 2022/23, the company employed some 18,400 people and generated sales of about 5.4 billion euros. With over 80 companies, the TRUMPF Group is represented in nearly every European country as well as in North America, South America and Asia. The company has production facilities in Germany, France, the United Kingdom, Italy, Austria, Switzerland, Poland, the Czech Republic, the United States, Mexico and China. Find out more about TRUMPF at www.trumpf.com.