With climate change getting worse, people have become more conscious of their impact to the environment. Companies are receiving growing pressure to address ESG (Environmental, Social, Governance) concerns, striking a balance between their profitability and social impact. Environmental policies like Electronic Product Environmental Assessment Tool (EPEAT), 100% zero-emission vehicle (ZEV) acquisitions by 2035, and circular economy action plan are also stimulating companies to go greener. One important business goal is to achieve design for recycling and make products using recycled content. For instance, in automotive industry, Ford has been using ocean plastics to replace vehicle parts. Dell has developed easier-to-recycle computers and aims to integrate at least 50% of recyclates in all their products by 2030.

Although many have been implementing the concept of design for recycling and some already succeeded, it remains a challenging task. As a designer, you are very likely to face these problems during the product design process:

- How to find suitable recycled materials that have similar properties as virgin plastics

- How to reduce uncertainty when working with recycled materials

- How to validate the right product designs and ensure product quality

- How to reduce the cost of rework and scrap during manufacturing

These problems may seem daunting at first (and they are!), but they will be a lot easier when you have the right tools.

Moldex3D Material Center

Provide you with accurate recycled material information

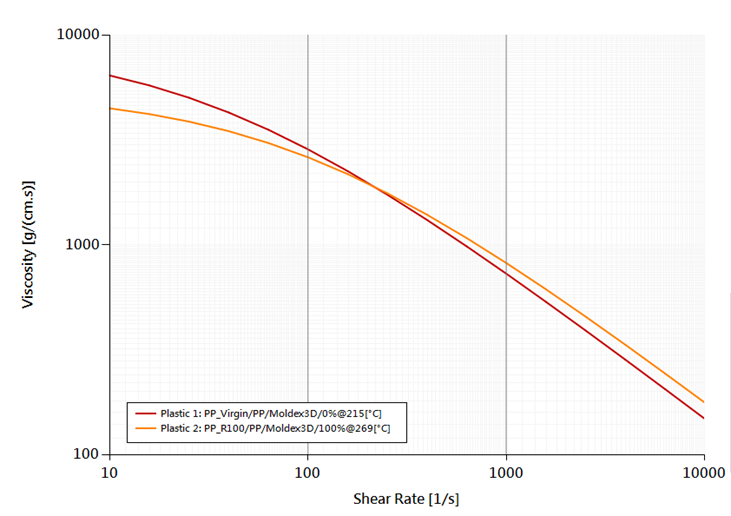

Choosing ideal materials in the design phase is crucial to reduce the failure rate in production and guarantees good molding behavior. However, recycled plastics have very different physical properties compared to the virgin materials due to molecular structure breakdown and number of regrind cycles. To get accurate material data, you can submit a material testing request to Moldex3D Material Center, which is equipped with high-quality measurement instruments and ISO 17025 accreditation.

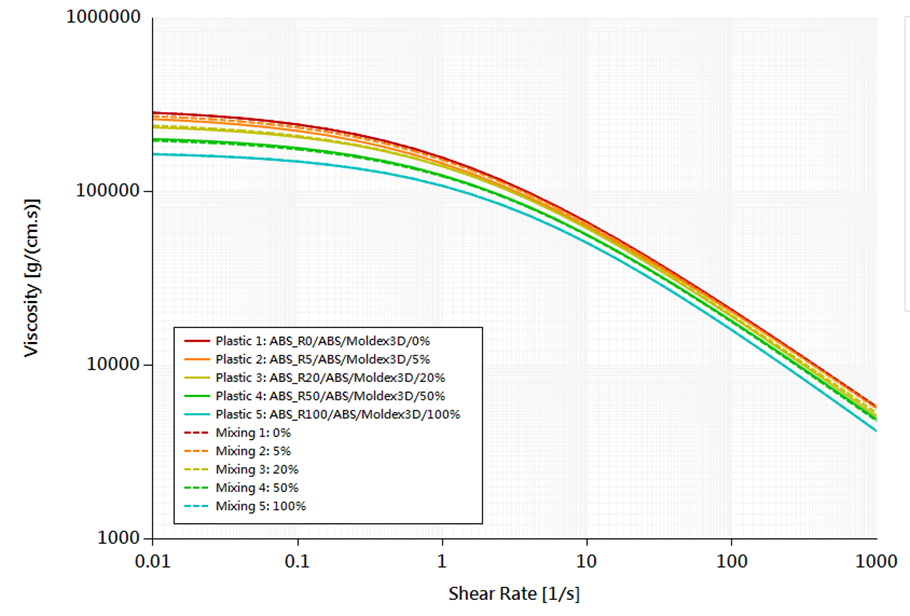

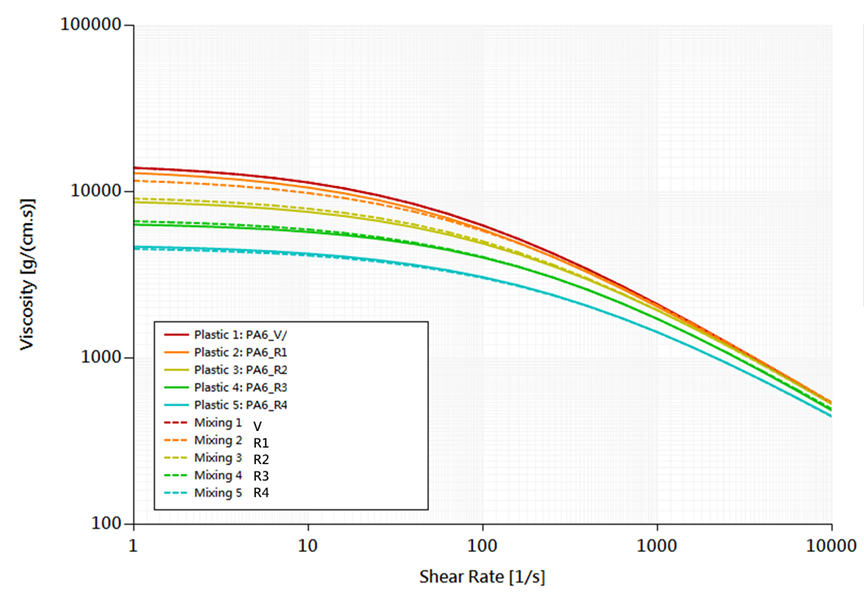

Our Moldex3D experts will run controlled measurement tests on the provided recycled material and virgin material. Material data will be available via a customized app, which will include shear viscosity from 5 different mixing percentages and how shear viscosity will be affected by the number of recycling, helping you find the blends with similar processing properties to the virgin plastic.

This data can be applied into CAE analysis to ensure more accurate simulation, which will be further explained in the next session.

Moldex3D Molding Simulation Software

Simulate molding results to solve potential defects and validate design for recycling

When developing a new product design, we need to consider a lot of things:

- How is the design for manufacturability (DFM)?

- Does the product meet our quality standards?

- Are there any potential design problems? (Shrinkage, warpage, sinks, internal stress, etc.)

- Is this the most optimized design?

Design for recycling makes the process more complicated because the properties of recycled materials are different from virgin plastics and can largely affect the molding results. Also, many traditional design and manufacturing methods such as insert molding and adhesive bonding must be replaced by Design for Recycling techniques to create circular plastic products. Normally, we need to run a lot of mold tests and rely on molders’ experiences to come up with the answers mentioned above. With Moldex3D molding simulation software and accurate material data, you can easily

…All before mold trials!

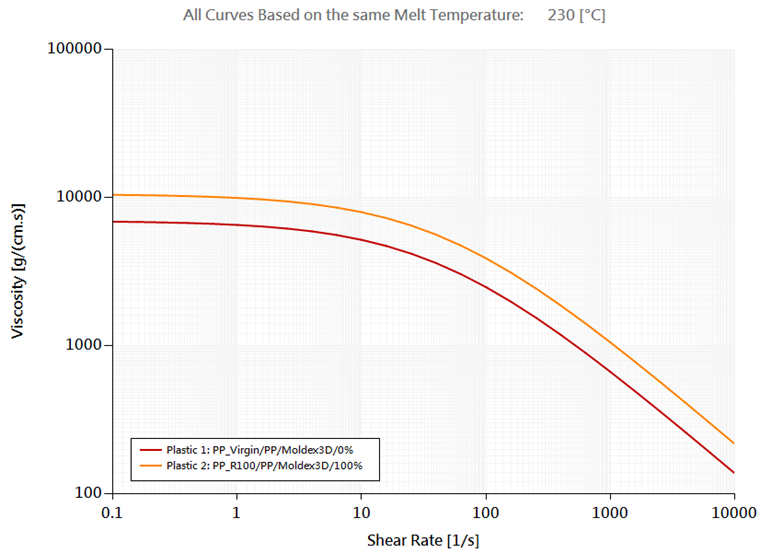

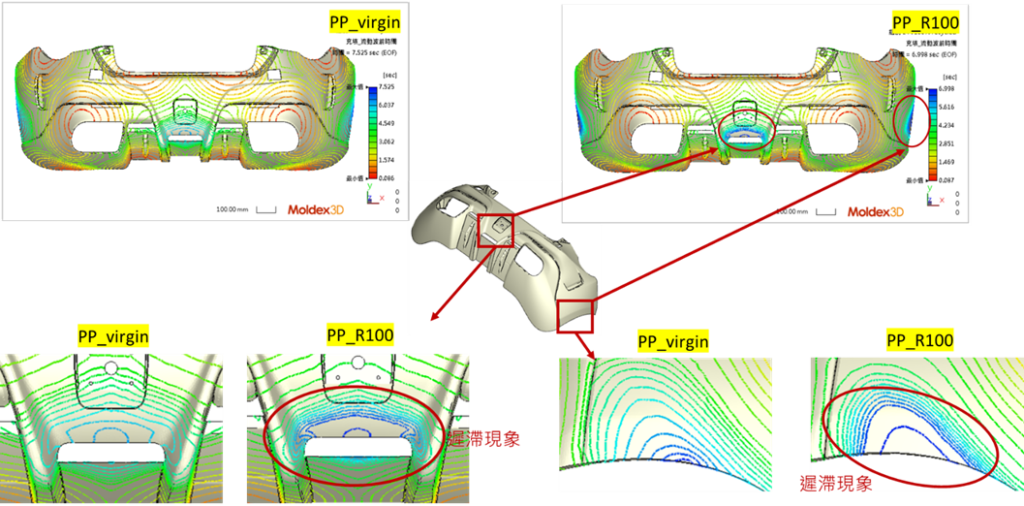

For instance, the pictures below show a common problem when using recycled material. The viscosity of PP_R100 (recyclate) is higher than virgin plastic PP, because recycling has changed its material properties.

Through Moldex3D simulation, the melt moves much slower than PP, leading to a severe flow hesitation. Short shots might occur at the end of the product.

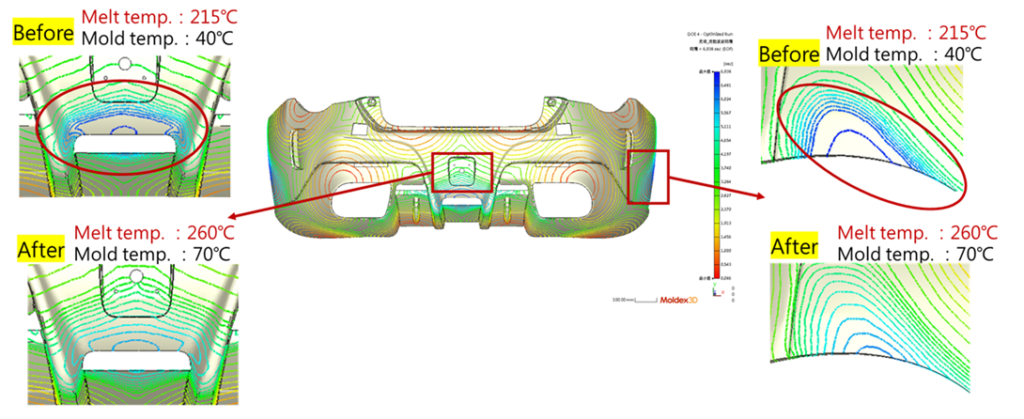

With this information in mind, we can adjust the processing conditions (melt temperature, mold temperature, flow rate, etc.) to fine-tune the viscosity curve and make it similar to the results of virgin material – PP to avoid potential design problems.

When we run the simulation again using the new processing conditions and viscosity, we can see that the flow hesitation has been improved.

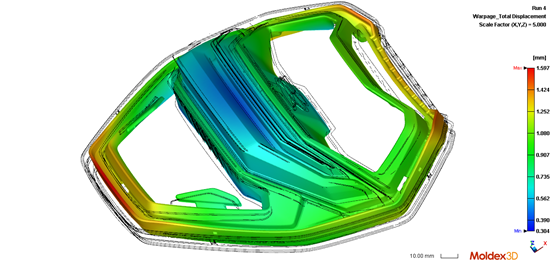

Moldex3D simulation software can also help you predict part warpage, so you can make simulation-driven decisions to better alleviate potential molding defects.

After simulating and validating the product designs, it is important to store the data in a proper way. The entire molding workflow contains lots of valuable data and experiences, including material properties, machine specifications, Moldex3D CAE analysis projects, mold information, mold tryout conditions, and molding results, etc. With Moldex3D iSLM, a web-based platform for mold design and plastic engineering, the data can all be managed and utilized as an enterprise’s database. No matter how many recyclates you are going to process, iSLM can help you store the critical data properly for future use.

In conclusion, with accurate material data and molding simulation software at hand, you get to test your design for recycling and find the most optimized solution within the fewest mold trials. What’s more? You can simplify your production by reducing scraps and cost of rework during trials, achieving sustainability in a whole new level.

Feel free to reach out to us to schedule a demo. We will show you what can be done through simulation.

Or get 30-day trial from Moldex3D Material Hub and access 8,000+ material data.

Guest post by : Jessica Huang, Marketing Specialist of CoreTech System (Moldex3D)