HOUSTON, TX, USA, Aug 14, 2025 – CPFD Software (CPFD) is pleased to announce that it has entered into a software licensing agreement with Lawrence Wang Ltd. (Lawrence Wang) and Shaanxi Xinli Nozzle Research and Development Co., Ltd. (Shaanxi Xinli) for use of CPFD’s Barracuda Virtual Reactor fluid-particle simulation software.

Lawrence Wang (Altrincham, UK) is a leading global sourcing and procurement company that provides materials, fabrication and bespoke production solutions for the chemical processing and energy industries.

Shaanxi Xinli (Xi’an, China) has 30 years’ experience as a leading equipment developer for the gasification industry, with specialty expertise in Coal Water Slurry Gasifier (CWSG) applications.

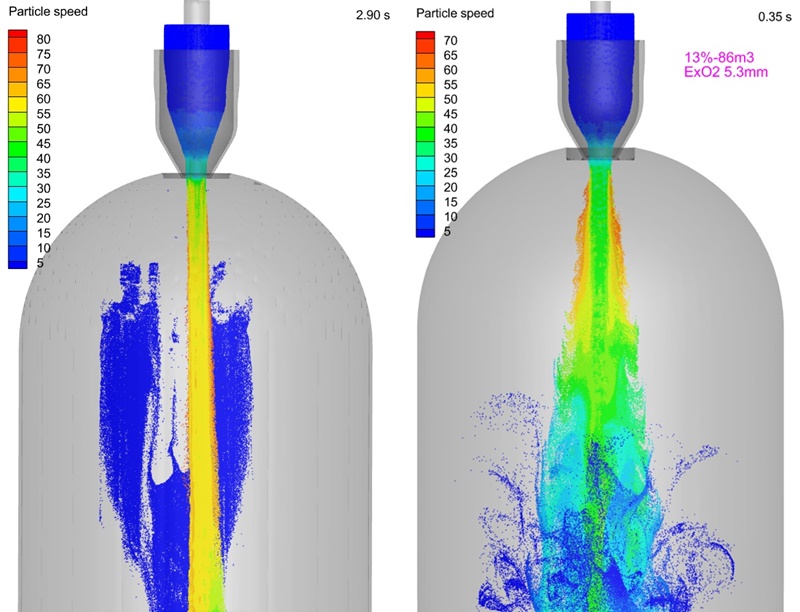

Barracuda Virtual Reactor simulation optimizes gasification nozzle design and operation, delivering significant performance and economic benefits. Key functions include: diagnosing nozzle status, optimizing internal structure/outlet size for better flow field/atomization, reducing pressure fluctuations, and determining optimal O₂ ratio and slurry load. It replaces lab tests and outdated 2D design methods (which ignore particle dynamics and coal properties), reducing shutdowns, carryover loss, and downstream fouling, while boosting carbon conversion and syngas yield.

“CPFD simulation has been successfully applied in numerous industrial cases, demonstrating that this technology is not only reliable and feasible, but has also garnered significant attention and recognition from industry peers,” said Dr. Hongming Yan, Chief Engineer of Shaanxi Xinli. “There is substantial market demand for this advanced simulation approach.”

“We were impressed to learn of the expertise demonstrated by Dr. Hongming Yan, Mr. Wang XiaoWei and the Shaanxi Xinli team in applying Virtual Reactor to CWSG applications for over 20 gasifiers, optimizing nozzle design and feed atomization while minimizing fluctuations and extending uptime,” said Peter Blaser, Vice President of CPFD. “We look forward to a long-term collaboration and global expansion through Lawrence Wang’s global reach.”

About Lawrence Wang

Lawrence Wang Ltd is a premier global sourcing and procurement specialist, providing high-performance special alloys and bespoke steel solutions tailored for critical engineering sectors—especially chemical processing and energy. With a focus on precision and excellence, they deliver materials in custom sizes and grades, alongside precision fabrication of intricate components and large-scale structures. By combining cutting-edge technology with deep engineering expertise, Lawrence Wang ensures enhanced durability, functionality, and safety for each project. Located in Altrincham, they’re committed to transforming ideas into reality through end to end, tailor made solutions that drive operational efficiency and reliability.

About Shaanxi Xinli Injector R&D Co,. Ltd.

Established in 1996, Shaanxi Xinli Injector R&D Co., Ltd. is a national high-tech enterprise specializing in the research, development, manufacturing, maintenance, and technological transformation of core specialized equipment for gasifiers in the coal chemical industry. With more than 25 years of continuous development, the company has replaced imports in the research and manufacturing technology of specialized equipment for gasifier units in the coal chemical industry, filling the domestic gap and taking a leading position in China. Its coal chemical equipment products are used in more than 50 customers in 31 cities and 13 provinces across China, covering energy fields such as coal chemical processing, petroleum coke, heavy oil, and secondary utilization of solid-liquid organic waste. The company’s product market share ranks among the top in China.

About CPFD Software

CPFD Software is advancing multiphase simulation and technology. Our flagship product, Barracuda Virtual Reactor, is a physics-based engineering software package that simulates the3D, transient, fluid-particle hydrodynamics, heat balance, and chemical reactions in industrial fluidized bed reactors and other fluid-particle systems.

Virtual Reactor enables researchers and engineers working with fluid/particle processes to explore a broad range of ideas, reduce physical testing costs, and minimize development risk, all while accelerating commercialization, scale-up, and overall time to market. For clients who already operate industrial units, Virtual Reactor allows engineers to determine the root cause of underperformance, reduce the risk of changes through virtual testing, and optimize solutions, all while maximizing reliability, uptime, and regulatory compliance initiatives.

The Virtual Reactor technology can be accessed via software licensing, services, or custom collaborative arrangements. For more information, visit https://cpfd-software.com.