PLYMOUTH, MI, USA, Aug 23, 2023 – Materialise, a 3D printing pioneer and leader in personalized medical solutions, accelerates the delivery of patient-specific medical implants to patients in the United States with the opening of a new 3D printing facility. Surgeons increasingly embrace 3D printing solutions as they recognize the added value it brings to personalized patient care, including more predictable and accurate surgical outcomes and time savings during surgery.

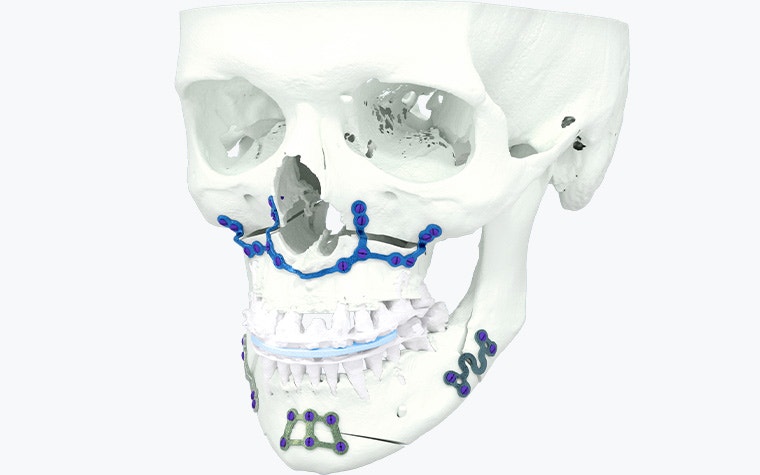

At the new facility in Plymouth, Michigan, Materialise specializes in the 3D printing of personalized titanium cranio-maxillofacial (CMF) implants. CMF implants are used for facial reconstructive surgery. Until now, Materialise manufactured titanium CMF implants solely at its 3D printing facility in Belgium. With a dedicated metal 3D printing facility in the US, the company can respond to surgeons’ needs with greater reliability while significantly reducing the delivery time of fully personalized implants to hospitals across the United States. This expansion of capabilities complements Materialise’s existing production of 3D-printed surgical guides and anatomical models in the United States.

“With the opening of our new metal 3D printing center in the US, we bring personalized care closer to US patients,” said Brigitte de Vet, Vice President Medical at Materialise. “The power of 3D printing, paired with our three decades of experience in 3D planning and medical manufacturing, allows us to accelerate the delivery of personalized medical implants. We take pride in leading the charge to revolutionize patient-specific care, and with our dedicated facility in Michigan, we further enhance personalized care in the United States.”

The advent of technologies such as 3D printing and advanced visualization techniques has transformed personalized patient care. Patient-specific 3D printed medical solutions include anatomical models for diagnostic purposes and surgical guides and implants to enhance accuracy and efficiency. These solutions are designed to bolster surgeons’ comfort before and during surgery, leading to more predictable and accurate surgical outcomes. As a result, surgeons increasingly adopt 3D printing as part of their medical practices to bring personalized care closer to patients and to reduce overall costs.

Materialise has more than three decades of experience in developing medical solutions and offers a comprehensive range of 3D-printed guides and implants. The company produces 280,000 personalized 3D-printed instruments and implants per year, including 160,000 for the US market. Materialise has pioneered numerous groundbreaking medical 3D printing applications. In 2017, it introduced one of the first personalized CMF implant portfolios in the United States. In 2021, its innovative 3D planning and 3D printed instruments played a pivotal role in the world’s first simultaneous double hand and face transplant that was successfully performed at NYU Langone Health in Manhattan, New York.

About Materialise

Materialise incorporates more than three decades of 3D printing experience into a range of software solutions and 3D printing services that empower sustainable 3D printing applications. Our open, secure, and flexible end-to-end solutions enable flexible industrial manufacturing and mass personalization in various industries — including healthcare, automotive, aerospace, eyewear, art and design, wearables, and consumer goods. Headquartered in Belgium and with branches worldwide, Materialise combines the largest group of software developers in the industry with one of the world’s largest and most complete 3D printing facilities. For more information, visit https://www.materialise.com.