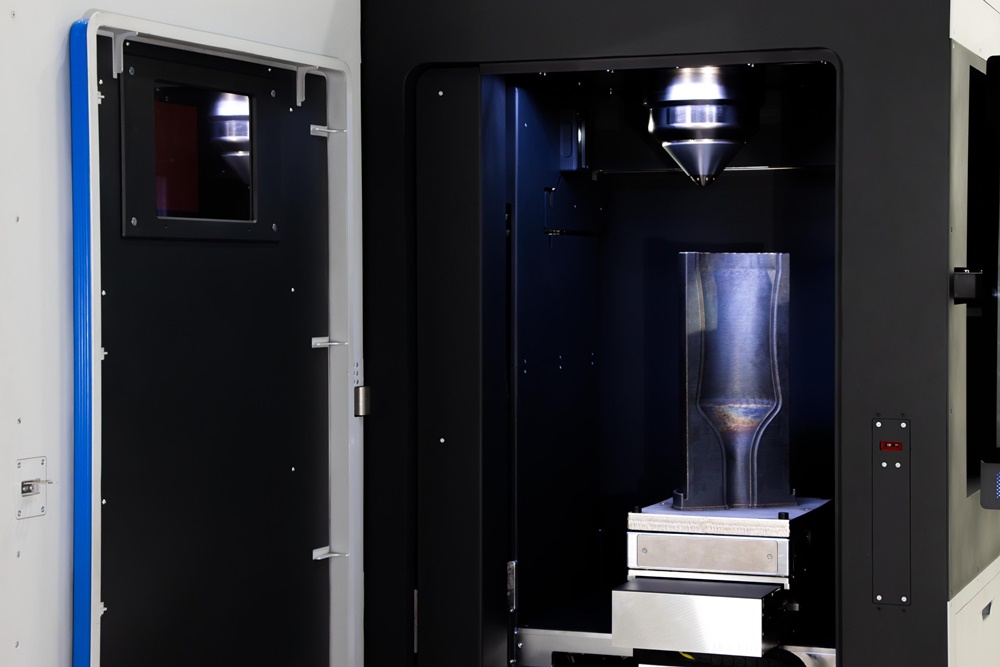

LINARES, Spain, Mar 13, 2024 – Meltio, the leading manufacturer of wire-laser metal deposition systems takes a leap forward and presents a new generation of metal 3D printer that was conceived to introduce metal additive manufacturing to the world of industrial production outside of niche areas.

The new Meltio M600 is designed to solve problems of long lead times, costly stock-keeping, and increasingly fragile supply chains, thanks to its unique metal 3D printing technology. This new system increases productivity and reduces manufacturing costs, brings new materials to the table, and most importantly is ready to perform 24/7 with minimal operator interaction for autonomous production.

Lukas Hoppe, R&D Director at Meltio says: “The design brief for the new Meltio M600 was to imagine what the perfect 3D printer for the machine shop would look like. The vast majority of metal 3D printed parts require post-processing which is carried out in the machine shop and since our ambition is to push the large-scale adoption of metal additive manufacturing we have a very clear vision that the modern machine shop is the ideal point of entry.

Manufacturing faces many challenges globally, from long lead times and stock-keeping costs caused by long and fragile supply chains to an ever-growing pressure to lower costs and reduce emissions.

3D Printing has huge potential to address these issues as it helps reduce lead times, and manufacturing dependencies by printing parts in-house, reduces warehouse inventory as the raw material can be transformed into the final part on demand, and reduces costs by applying material only where it is needed”.

To make this new tool for machine shop use a reality, the Meltio M600 is the first Industrial wire-laser metal 3D printer that incorporates, among other technological advances, a Blue Laser deposition head. These lasers improve energy absorption and printing efficiency across the metal spectrum and open up new material possibilities while reducing the carbon footprint for production.

These attributes make the Meltio M600 an exciting proposition for the manufacturing industry as a whole and get a lot of traction from a wide range of sectors: automotive, aerospace, oil & gas, mining, and defense.

Lukas Hoppe continues: “The Meltio M600 for us was really the next logical step on our continuous journey towards mass adoption of Wire-Laser DED, the process all Meltio systems are based on. We began this work in earnest in 2019 when we started to leave the prototyping space with the launch of the Meltio M450. After learning from and improving the technology for three years, the time was finally ripe for us to work on the next system.

Our goal with the Meltio M600 was to strike the right balance between machine size, cost, and productivity while being uncompromising on quality, reliability, and ease of use. To achieve this, we did not just create a “scaled up” M450, instead, we developed every single part of the machine from scratch to take the technology to the next level, based on the learnings of having manufactured and installed over 300 Laser DED machines.”

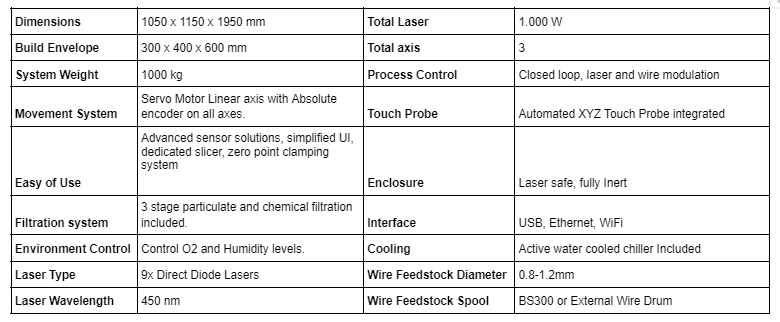

Meltio M600 Spec Sheet:

About Meltio

Meltio takes metal additive manufacturing to the next level by developing high-performance, affordable, and easy-to-use metal 3D printing solutions using wire-laser metal 3D printing technology. The company’s mission is to delight customers, partners, and employees by pioneering the development of affordable metal 3D printing systems that are reliable, safe, and powerful, continually reinforcing their status as disruptors. For more information, visit https://meltio3d.com.