AACHEN, Germany, Aug 31, 2020 – ModuleWorks announces the release of its 2020.08 CAD/CAM software components. This is the second major release of 2020 and is available now for download from the ModuleWorks website.

Each ModuleWorks release contains new and enhanced features across the entire product range. The highlights of the latest release are presented here. They include new performance and quality enhancing features for rotary machining, additive manufacturing, 3-axis machining, simulation and the ModuleWorks Multi-Axis Post Processor (MultiXPost).

Rotary Machining

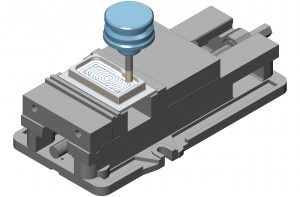

Axis offset for roughing cycles

This new feature enables users to perform roughing cycles with an axis offset for rotary machining. The tool cuts with the cutting edges instead of the tool center to achieve more stable cutting speeds and close-to-diameter cutting with non-spherical tools. The offset is always in the opposite direction to the direction of rotation and automatically changes position when the rotation direction changes. This movement is linear to prevent damage to the tool and ensure a safe cutting process.

Additive Manufacturing

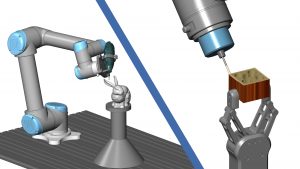

3+2 Additive manufacturing for fused deposition modeling

ModuleWorks 3+2 axis additive manufacturing uses the full capabilities of 5-axis printing machines to print extreme overhang areas without the need for support structures. This accelerates the manufacturing process and delivers a higher quality finish with reduced staircase effects.

3-Axis Machining

Profile pass for adaptive and offset roughing

To improve the quality of the machined product, additional cuts are added along the part boundaries to remove any remaining uncut cusps. A range of advanced options, such as cutter compensation and tangential arc, gives users full control over the creation of the toolpath and makes it easier to create the finishing pass.

Multi-Axis Post Processor (MultiXPost)

Post on any n-axis machine

MultiXPost now supports posting on n-axis machines. This opens new possibilities for generating G-code for n-axis machines and for simulating robotic applications. To provide full control over the machine movements, MultiXPost offers a range of new parameters and returns the machine axis values that can be used to drive a simulation or generate an NC G-code file.

Simulation

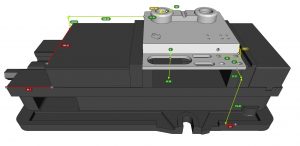

Smart measurement of stock and arbitrary meshes

Smart-measure is a new interactive touch-screen tool for quickly and accurately measuring the stock and arbitrary meshes. Automatic feature identification and intelligent snapping help users to set precise measurement points and then use the convenient drag & drop functionality to measure distances between the stock and the machine as well as depths, clearances, angles and radii.

For further details about the ModuleWorks 2020.08 release, see the latest ModuleWorks YouTube videos: What’s New in ModuleWorks 2020.08.

About ModuleWorks

ModuleWorks is the leading software component provider for the digital manufacturing industry. With over 200 employees and 900 man years of software development, ModuleWorks’ expertise in toolpath creation and simulation is recognized throughout the industry and its software components are already optimizing the performance and quality of over 500,000 installed seats of CAD/CAM and CNC software around the world. From standard products to exclusive development projects, ModuleWorks helps companies to bring their vision of Industry 4.0 to life. With its comprehensive portfolio of cutting-edge software components, ModuleWorks enables its customers to optimize their CAD/CAM solutions and connect to CNC/MTB systems to increase their competitiveness and help them Get There Faster. For more information, visit https://www.moduleworks.com.