AACHEN, Germany, Dec 10, 2025 – ModuleWorks announces the 2025.12 release of its software components for digital manufacturing and digital factory. This latest release of the ModuleWorks SDK offers a range of new, automated features designed to enhance machining efficiency, process safety and part quality.

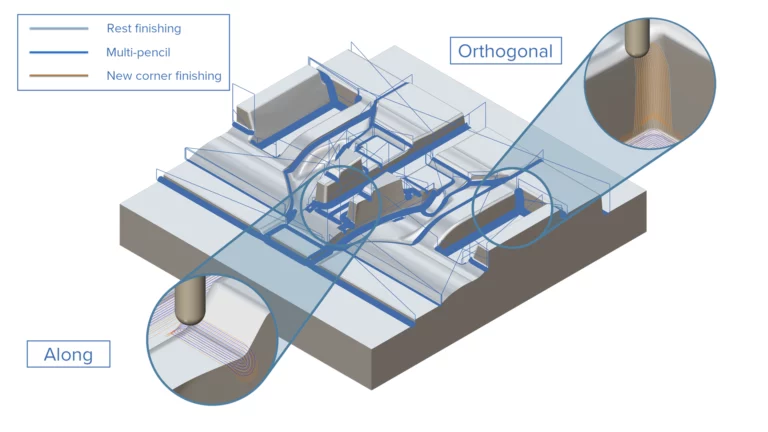

New Corner Finishing for Mold and Die

Complex molds and dies often feature deep pockets and sharp internal corners that are difficult to machine due to limited access and tooling constraints. Traditional 3-axis milling relies on long, slender tools, leading to higher costs, greater risk, and residual material that requires manual finishing.

ModuleWorks 2025.12 introduces a new Corner Finishing toolpath, designed to overcome these challenges by detecting uncut stock, generating stable tool center lines, and merging optimized paths to minimize repositioning. It automatically adjusts toolpath strategies for both steep and shallow areas, ensuring accurate material removal, high surface quality and reduced manual polishing.

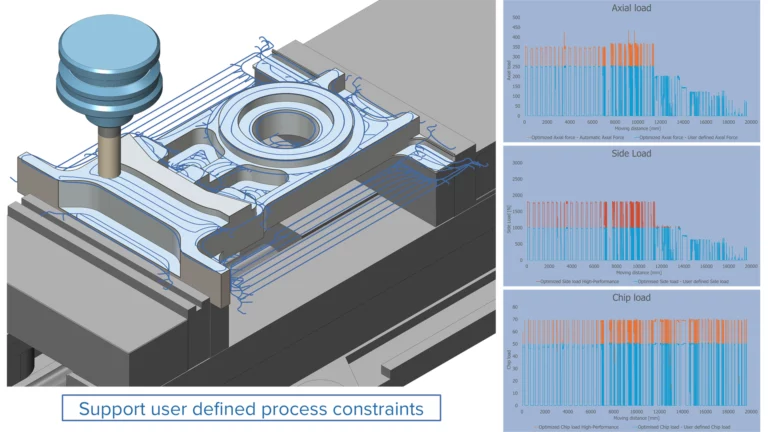

FeedControl – User Defined Process Constraints

FeedControl dynamically adjusts toolpaths according to cutting forces and individual machine capabilities, helping engineers maintain stable cutting conditions, extend tool life and speed up machining cycles.

ModuleWorks 2025.12 offers a new option for defining custom process constraints directly within the FeedControl interface. By specifying parameters such as side load, chip load and power-torque limits, users can now fine-tune toolpaths to optimize machining efficiency and safety.

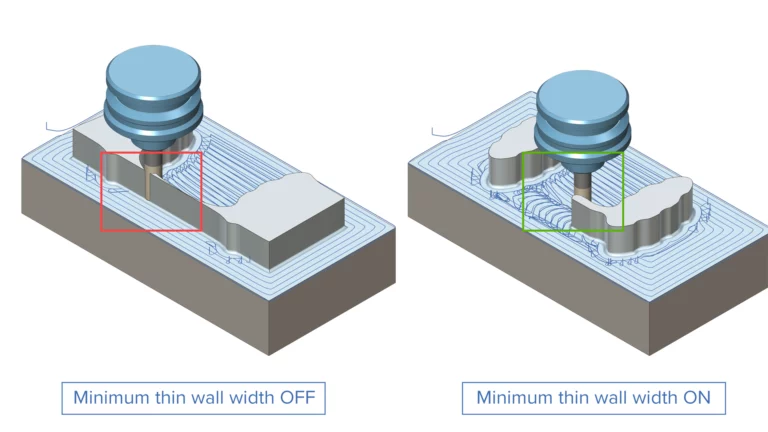

Adaptive Roughing – Thin Wall Avoidance

Roughing processes can unexpectedly create thin stock walls, leading to unstable cutting conditions and a higher risk of damage to the tool or part.

To overcome this, ModuleWorks 2025.12 offers a new feature that actively monitors and manages stock wall thickness throughout the machining process. It is designed to ensure consistent tool engagement and improve overall process reliability in high-speed operations.

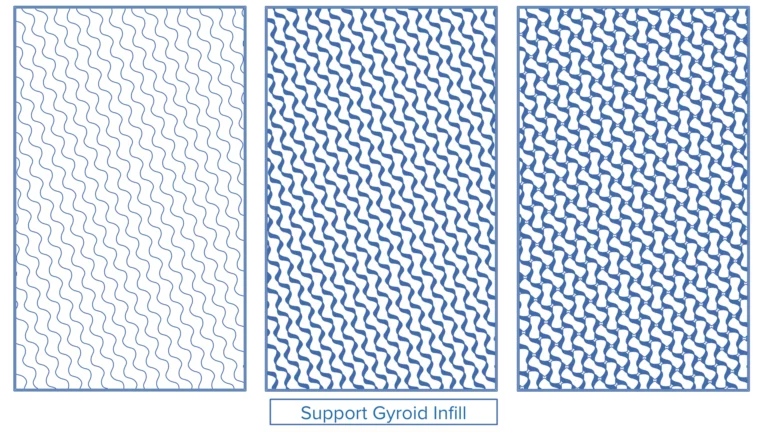

Fused Deposition Modeling – Gyroid Infill

Gyroid patterns are known for their intricate, wavy structures and excellent mechanical properties, but they are difficult to generate, requiring complex density calculations.

In ModuleWorks 2025.12, gyroid structures are now computed directly from an advanced mathematical formula that adapts to user-defined infill densities and path widths. This makes it easier for users to generate customized patterns while retaining all the mechanical benefits of the gyroid design.

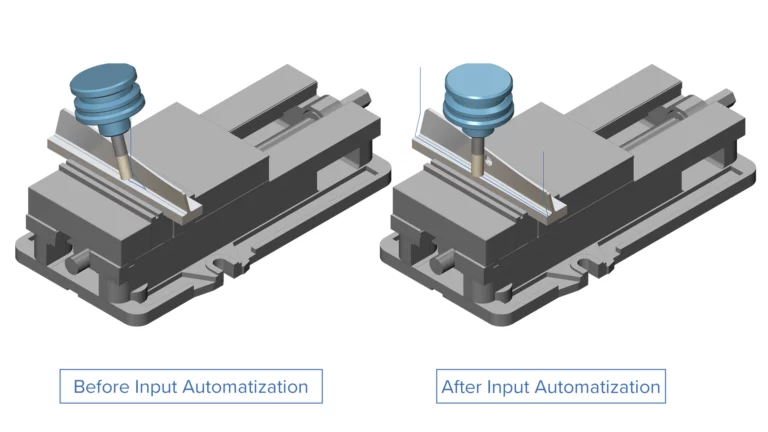

Swarf Machining – Input Automatization

ModuleWorks 2025.12 offers a major improvement for Swarf machining. The latest update introduces enhanced logic for reliably detecting guide curves on surfaces, even those with rounded boundaries. This overcomes previous limitations, enabling consistent curve selection regardless of edge geometry. It also simplifies and speeds up the programming workflow, making it easier for users to handle diverse part topologies and achieve consistent results in complex machining scenarios.

ModuleWorks 2025.12 is available for download from the ModuleWorks website.

For more details about these and the other new features and enhancements in the ModuleWorks 2025.12 release, see the ModuleWorks What’s New webpage: What’s New in ModuleWorks 2025.12.

About ModuleWorks

ModuleWorks is at the forefront of digital manufacturing software, playing a key role in enabling the efficient production of increasingly complex parts in an environmentally sustainable way. As a strategic partner to leading CAD/CAM vendors, CNC control makers, machine tool builders and cutting tool manufacturers, ModuleWorks develops software that powers solutions throughout the manufacturing industry which contributes to 16% of global GDP worth $16 trillion per year.

Founded in 2003, ModuleWorks has grown to over 200 employees and already invested 1,700 person-years of software development in toolpath and simulation technologies that form the core of manufacturing processes. In the CAD/CAM area alone, ModuleWorks has a market share of 90%, enhancing the performance and quality of over 500,000 installed seats of CAD/CAM and CNC software worldwide.With a comprehensive portfolio of cutting-edge software components and the capacity to address emerging and niche technologies like AI, cloud, automation, additive, robotics and digital dentistry, ModuleWorks is committed to shaping the future of digital manufacturing with its partners, empowering the industry to Get There Faster.