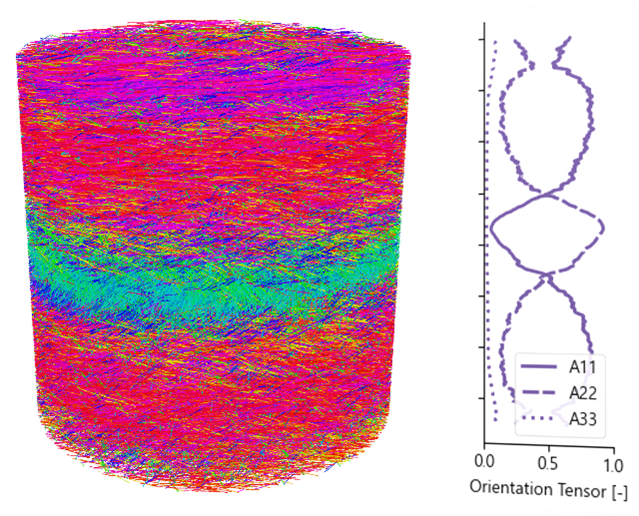

HSINCHU, Taiwan, Jun 10, 2024 — Applications of reinforced composite materials are getting more and more popular in response to the lightweight and low-energy demands in the manufacturing. In order to predict and control the breakage or failure of an injection-molded plastic part, an accurate simulation on the fiber’s orientations inside is crucial for the following structural analysis. But the fiber model’s parameters would need some fine-tuning before being applied on the real part’s simulation workflow. As a result, it was natural for Moldex3D, a cutting-edge and widely used molding simulation in the industry, and Xnovo Technology, a pioneer in advanced X-ray imaging solutions, to offer together an advanced calibration for fiber parameters based on scan experiments, empowering users to conduct reliable and accurate simulations.

“Simulation of fiber orientation is not a new technology and we created a great model for it, but with the input of real-life data it would be even more enhanced”, said Ethan Chiu, R&D Director at CoreTech System, the mother company of Moldex3D. “The top design and manufacturers are all implementing the digital twin concept so the precision requirement has also upgraded. Every little detail counts.”

“We are proud to support Moldex3D users with our advanced X-ray imaging solutions”, said Erik Lauridsen, CEO at Xnovo Technology. “By building on our proven expertise in 3D imaging and analysis, we are able to provide 3D fiber orientation characterization with unparalleled time-to-result and superior quality.”

This collaboration enables users to conduct simulations of 3D fiber orientation using calibrated fiber parameters, which is particularly valuable for defining the anisotropic mechanical strength and controlling molding shrinkage in fiber-reinforced components. By integrating Xnovo’s 3D fiber orientation characterization capabilities with Moldex3D’s simulations, users can achieve improved accuracy and reliability in their simulation analyses. And with the help of Moldex3D Studio API, computing iterations between the digital and physical data are automated on a large scale. For more information, please contact support.eu@moldex3d.com or info@xnovotech.com.

About CoreTech System (Moldex3D)

CoreTech System Co., Ltd. has been providing the professional CAE analysis solution for the plastic molding industry since 1995, and the simulation software “Moldex3D” is nowadays referenced worldwide. Committed to advanced technologies and solutions to meet industrial demands, CoreTech System has extended its sales and service network to provide local, immediate, and professional support to help customers troubleshoot from product design to development, optimize design patterns, shorten time-to-market, and maximize products’ ROI.

More information can be found at Moldex3D Website.

About Xnovo Technology

Xnovo Technology ApS is a Denmark-based company, providing state-of-the-art imaging solutions for academic and industrial materials research and quality control. Xnovo delivers novel, high-performing, and user-friendly 3D imaging tools for applications within the fields of engineering, materials & geosciences. The company is an offshoot of more than 20 years of synchrotron and diffraction imaging research at the Technical University of Denmark (DTU).

More information can be found at Xnovo Website.