Introduction to NC Shop Floor Programmer

Guest Post/Tutorial by Best Engineering Aids and Consultancies Pvt. Ltd. (BEACON India)

The NC Shop Floor Programmer is a foundational role within the 3DEXPERIENCE platform designed to simplify and accelerate programming of 2.5-axis and 3-axis milling machines, along with 2- and 4-axis wire EDM machines. Serving as an entry-level machining solution, it empowers manufacturing engineers and NC programmers to generate precise 3D parts through an intuitive and immersive digital environment.

At its core, the software offers a realistic virtual workspace where users can efficiently setup workpieces, assemble cutting tools, and simulate toolpaths to validate machining strategies before production. This simulation-driven approach helps detect potential collisions and material removal issues early, reducing costly errors on the shop floor.

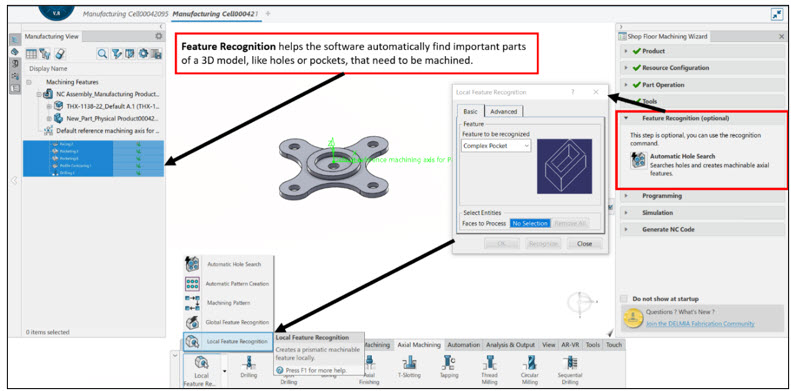

Seamlessly integrated with 3DEXPERIENCE SOLIDWORKS and cloud services, NC Shop Floor Programmer enhances collaboration by connecting design and manufacturing data, ensuring digital continuity throughout the process. Users benefit from guided workflows, automated feature recognition, and cloud-enabled resource access, supporting fast, standardized, and reliable NC programming in modern manufacturing environments.

Core Features and Functionalities

NC Shop Floor Programmer delivers a robust suite of capabilities tailored to streamline programming for 2.5-axis and 3-axis milling as well as 2- and 4-axis wire EDM machines. Central to its functionality is the Setup Wizard, which guides users through configuring workpieces and tools within a realistic 3D environment, dramatically reducing setup time and simplifying complex machine preparation.

Complementing the setup process, intuitive toolpath creation wizards assist programmers in defining operations like pocketing, contouring, roughing, finishing, and probing. These wizards feature context-sensitive menus and dynamic help icons that offer quick visual explanations, enabling even less experienced users to navigate options confidently without interrupting workflow.

A key productivity enhancer is the software’s automatic prismatic feature recognition, which detects machining features directly from part geometry. This functionality automatically generates a manufacturing view listing all drill holes, pockets, and milling areas, allowing rapid generation of tailored toolpaths without manual feature definition.

For 3-axis milling, NC Shop Floor Programmer incorporates advanced machining strategies covering the full spectrum from roughing to finishing. Users can select from high-efficiency approaches such as helical or spiral roughing and precision finishing strategies including deburring or Z-level contouring. The software continuously analyzes tool assemblies and stock material during operation sequencing to produce optimized, collision-free toolpaths.

The built-in toolpath simulation module offers detailed visualization of material removal and machine motion, enabling early identification of collisions, gouging, or remaining stock irregularities. Programmers can quickly verify or edit toolpaths, thus preventing costly errors on the shop floor and ensuring efficient machining cycles.

Wire EDM programming is fully supported with dedicated 2- and 4-axis operation modes. Users can define synchronized wire paths and simulate cutting sequences to verify complex contours. The solution also enables reuse of wire EDM strategies through templates, facilitating consistency and reducing programming effort for repetitive setups.

Throughout the interface, context-based menus and interactive help panels provide a responsive and user-friendly experience. Illustrations dynamically update as parameters are adjusted, fostering better understanding and decision-making without requiring extensive training or reference to external documentation.

Advanced Simulation, Verification, and Automation

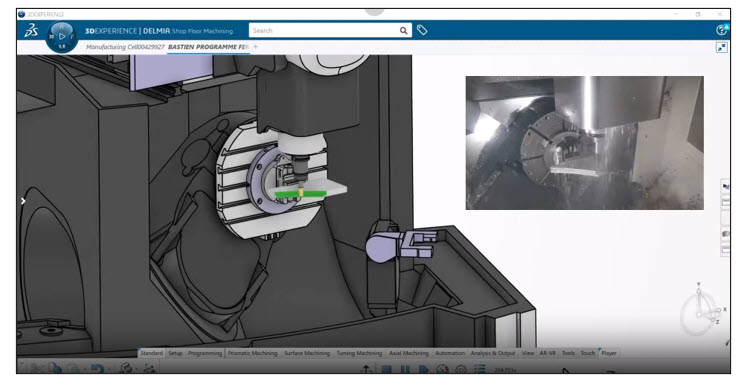

NC Shop Floor Programmer excels with its state-of-the-art 3D toolpath simulation capabilities that immerse NC programmers in a highly detailed virtual machining environment. This simulation faithfully reproduces the entire machining process, enabling users to visualize every movement of the cutting tool relative to the workpiece. Programmers can scrutinize simulated material removal, detect gouges and collisions early, and verify the correctness of tool changes and machine kinematics before any actual machining takes place.

The platform’s collision detection highlights risk such as tool interference or near-misses at user-defined safety thresholds, helping prevent costly and dangerous errors on the shop floor. Additionally, the material removal simulation provides precise analyses of the remaining stock throughout operation sequences, empowering programmers to optimize cutting strategies and reduce unnecessary machining passes.

Beyond visualization, NC Shop Floor Programmer integrates powerful automation and standardization tools through reusable templates and knowledge-based rules powered by Knowledgeware. Users can capture best practices and company-specific expertise in templates that automatically apply machining parameters based on part features, significantly accelerating programming workflows while ensuring process consistency.

- Reusable templates: Store and recall optimized machining processes to reduce redundant programming efforts.

- Knowledgeware objects: Enable intelligent automation by associating machining logic and constraints directly to NC programming elements.

- Batch processing: Leverage background computation of toolpaths to maximize user productivity without workflow interruption.

Together, these simulation, verification, and automation features empower NC programmers to produce error-free, collision-free, and efficient toolpaths within a comprehensive 3D contextual environment. This robust validation framework significantly reduces programming risks, shortens development cycles, and boosts manufacturing throughput by delivering precise, optimized machining operations every time.

Recent Enhancements in the 2025 Release

The 2025 update of NC Shop Floor Programmer introduces several cutting-edge improvements aimed at boosting user productivity and streamlining machining workflows. A redesigned, dedicated user interface now simplifies searching for machines, cutting tools, and accessories by integrating favorites and search history, enabling faster access to frequently used resources and reducing setup time.

Machine movement optimization between machining operations has been enhanced with an automatic path calculation feature. This intelligent system respects machine kinematics and collision avoidance, including advanced handling of tool rotations via Rotate Tool Center Point (RTCP) control. Users gain real-time visibility of toolpath costs and tool life warnings in the process tree, helping to plan more efficient and safer machining sequences.

A significant productivity boost comes from the introduction of AI-guided machining cycle recommendations. Leveraging neural networks trained on typical geometries and operations, this assistance guides both novice and experienced users in selecting optimal machining strategies—such as pocketing, contouring, or drilling—based on proven best practices.

The update also introduces robust support for multi-part setup management, enabling machining of grouped components in one run to maximize machine utilization. Enhanced simulation reliability is achieved through automatic detection and removal of floating material chunks, preventing false collision alerts and improving confidence in material removal validation.

Additional workflow acceleration is provided by a new batch mode for toolpath computations, allowing background processing of lengthy calculations while users continue other tasks uninterrupted. Furthermore, a nesting command optimizes placement of multiple parts on raw material blocks, reducing waste and increasing material utilization efficiency.

Together, these enhancements empower NC programmers with intelligent assistance and workflow automation, driving faster programming cycles, reducing errors, and supporting higher throughput on the shop floor.

Benefits and Practical Impacts for Manufacturing

NC Shop Floor Programmer delivers substantial time savings by leveraging an intuitive interface equipped with setup wizards and context-sensitive menus, allowing programmers—regardless of experience—to rapidly generate accurate NC programs. By minimizing idle machine motions and optimizing toolpaths, it effectively maximizes machine tool utilization, boosting production throughput while lowering operational costs.

Its comprehensive 3D virtual machining environment intricately models tools, cutters, and machine kinematics, enabling early detection of collisions or toolpath inefficiencies to mitigate production risks. This immersive simulation ensures reliable and safe machining, reducing scrap and rework.

Furthermore, seamless integration within the 3DEXPERIENCE platform fosters collaboration across teams and promotes intellectual property reuse via templated machining strategies. Precise, up-to-date NC code generation supports digital continuity, enhancing both quality and cost efficiency in real-world manufacturing environments.

Conclusion

NC Shop Floor Programmer stands as a vital tool within the 3DEXPERIENCE ecosystem, empowering users to achieve exceptional precision and efficiency in milling and EDM programming. By fully leveraging its advanced setup wizards, feature recognition, simulation, and automation capabilities, manufacturers can streamline workflows and enhance collaboration across teams.

Guest Post/Tutorial by Best Engineering Aids and Consultancies Pvt. Ltd. (BEACON India)

To know more details, please reach out to BEACON India at: Phone: +91 7406663589

Email ID: info@beacon-india.com

Website: http://beacon-india.com

Request a Quote Now: https://www.beacon-india.com/request-a-quote

Request a Demo Now: https://www.beacon-india.com/request-a-demo