WESSLING, Germany, Mar 11, 2024 – CAD/CAM developer OPEN MIND Technologies will be exhibiting at MACH 2024 with its biggest-ever stand at the UK’s showpiece manufacturing event. From the 15th to the 19th of April on Stand 240 in Hall 17, OPEN MIND Technologies UK will be presenting the innovative technologies of its hyperMILL CAD/CAM suite with live demonstrations of the latest 2024 Version that is imminently set for release.

At MACH, OPEN MIND UK will highlight its pioneering technologies for digital process chains whilst showcasing its innovative advancements for connected manufacturing, automation, turning, Hummingbird MES and solutions for additive manufacturing.

One of the latest innovations that is gaining huge traction in the industry is the new Hummingbird Manufacturing Execution Systems (MES). The agile MES solution that enables users to improve and streamline the planning, control, automation and optimization of processes across manufacturing operations will be presented for the first time at MACH 2024. Too often, the right information, data and materials are not in the right place at the right time. Hummingbird eases entry into the digitalized world of manufacturing for customers with a tailored solution that allows users to choose the modules they require to gain complete control of their processes – and then expand the system step by step as needed.

The OPEN MIND UK team will also present the latest hyperMILL TURNING Solutions that have expanded exponentially since MACH 2022. The latest updates in hyperMILL TURNING Solutions include technologies for turning, turn/mill and mill/turn machines – making the suite ideal for all corresponding machine configurations. In version 2024, hyperMILL TURNING developments will include CAD for CAM functions for rotary contours, finishing paths for grooving, a ‘remove rings’ function, a 2D stretch command and a new tool turret support that via hyperMILL VIRTUAL Machining can create a detailed map of all tools in a turret to create a seamless NC code simulation. The new enhancements will simplify the creation of chamfers, contours, radii and undercuts, create uniform allowances for finishing when grooving, reliably remove ring chips from components, quickly and easily adapt parametric 2D contours and much more. Furthermore, Heidenhain CNC systems as well as Siemens controls are now supported with the latest mill/turn modules whilst the ‘Connected Machining’ interface also supports FANUC control systems. These updates identify the exponential development rate and the associated compatibility of hyperMILL’s TURNING suite with an ever-increasing range of machine tool types.

hyperMILL TURNING Solutions

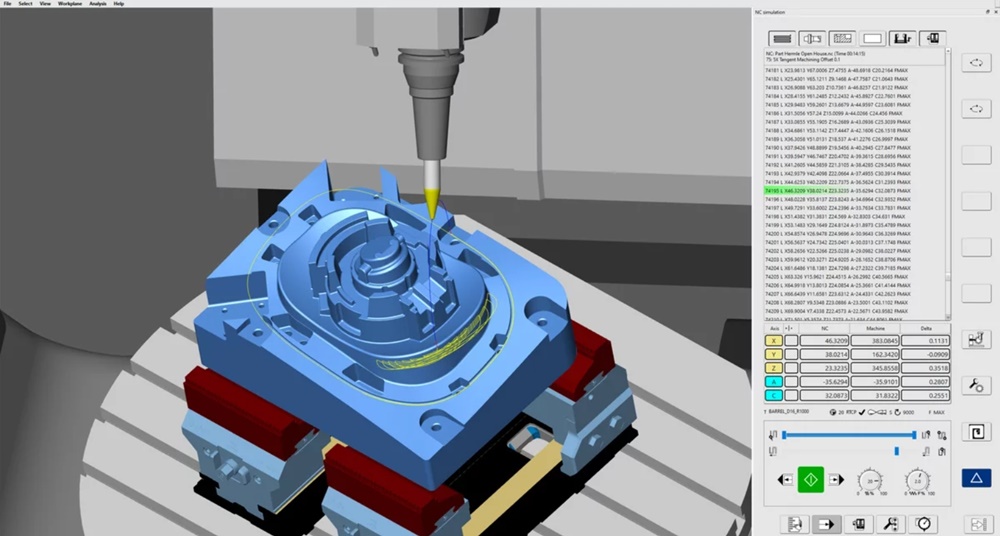

Bidirectional communication with machine tool controls is particularly important in networking with other systems along the process chain. At MACH, there will be demonstrations of hyperMILL® VIRTUAL Machining that closes the gap between the CAM system and the physical machine environment. If the CAM software can work with a digital twin of the physical machining process, then this opens up new options for generating, optimising and simulating the NC code safely. hyperMILL® BEST FIT is an impressive example of this. It is a new type of component alignment system for the subsequent processing of cast, welded or additively manufactured components. This sees the NC program adapt to what is physically happening in the workspace, rather than the clamping being adapted to the NC program, which has been standard practice until now.

As well as added functionality for 5-axis machining, mill/turn, Hummingbird MES, Connected Machining and hyperMILL VIRTUAL Machining, OPEN MIND UK experts will be on hand to discuss hyperMILL® ADDITIVE Manufacturing. This technology opens up the flexible possibilities of highly complex 5-axis simultaneous machining to the Direct Energy Deposition (DED) and Wire Arc Additive Manufacturing (WAAM) processes. NC codes can be conveniently programmed and automatically simulated for collision avoidance and as an end-to-end software solution, this enables efficient hybrid machining with additive and subtractive machining on a single machine.

Visit OPEN MIND Technologies UK at MACH 2024 from 15th to 19th of April on Stand 240 in Hall 17.

About OPEN MIND Technologies AG

OPEN MIND Technologies AG develops and sells innovative CAD/CAM solutions that generate optimized NC milling and turning programs for machine tools from digital models.

Manufacturers from a broad range of industries around the globe have decided to go with OPEN MIND products because they enable cost-effective and efficient manufacturing. This leads to models, prototypes, tools, molds, prismatic workpieces, integral components and more, all in impressive quality:

- Modeling and prototyping

- Tool and mold manufacturing

- Production machining

- Automotive industry

- Aerospace industry

- Energy industry

- Medical implant manufacturing

- Jewelry and watch industry.

OPEN MIND is active in all of the important markets, such as Asia, Europe and North America, with international subsidiaries and a global network of sales partners. OPEN MIND Technologies AG is a man and machine company. For more information, visit http://www.openmind-tech.com/en.