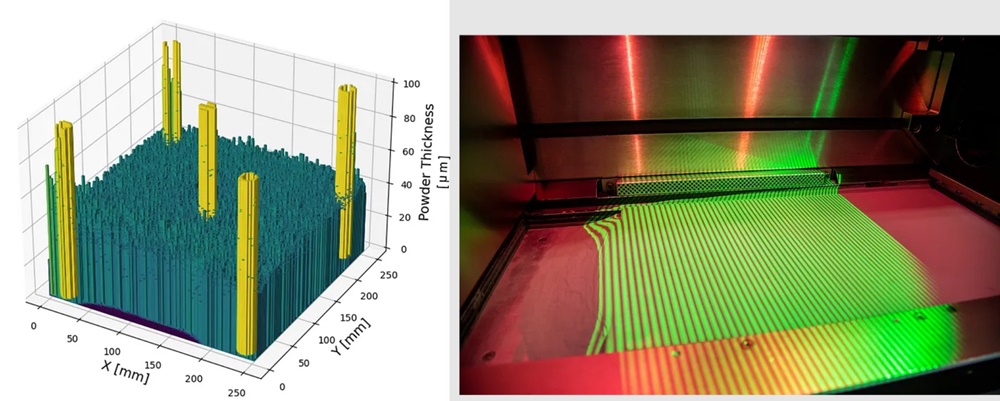

CHICAGO, IL, USA, Mar 12, 2024 – Phase3D, a Chicago-based company commercializing in-situ monitoring for additive manufacturing (AM), is excited to announce the launch of True Layer Thickness. This toolkit measures the quantity, in microns, of metal powder spread across the build area, certifying uniform distribution for every layer of every build. The innovation sets a new standard in inspection for metal powder bed fusion (PBF), providing a new in-situ monitoring toolkit for production scale AM.

Regulated industry like aerospace, medical, and energy seeks to advance AM to meet critical use applications through in-situ monitoring to reach born certified parts. Phase3D has worked with a prominent aerospace company to develop the True Layer Thickness toolkit, addressing a critical need to ensure high quality part production.

Key Aspects of Phase3D’s True Layer Thickness are:

- Objective Data — True Layer Thickness uses patented Fringe in-situ monitoring technology to create quantifiable measurements, in microns, of how much powder is spread during the metal PBF process.

- Precision and Consistency — This toolkit ensures precise inspection of the amount of deposited metal powder for every layer of every build.

- Industrial Solutions — Tailored to the challenges of industrial manufacturing, True Layer Thickness addresses the requirements for industrial applications beyond aerospace including defense, energy, medical, and more.

- Seamless Integration — True Layer Thickness integrates seamlessly with Phase3D’s existing in-situ monitoring system, Fringe, which can be added to most metal AM machines to support product development to production.

Dr. Niall O’Dowd, CEO and Founder of Phase3D, expressed enthusiasm about the release, stating, “We are pleased to introduce True Layer Thickness. This new toolkit underscores our commitment to advancing AM for the benefit of widespread adoption of the technology for critical use applications.”

The True Layer Thickness toolkit is a big step forward for the AM industry to reach born certified production. Fringe in-situ monitoring and True Layer Thickness provide objective measurement data to inspect every build in real-time. This toolkit will be available for all Phase3D customers and can be seen at AMUG 2024, in Chicago, IL at Booth 101 in Salon D.

About Phase3D:

Phase3D is on a mission to empower the Additive Manufacturing industry by offering a trusted part quality assurance technology. Fringe, Phase3D’s flagship in-situ monitoring system, is an inspection tool which uses structured light to objectively detect and classify print anomalies which lead to part defects. Phase3D produces quantitative height maps and now layer thickness measurements for the AM process. Fringe is the only commercially available system that can measure out-of-plane surface anomalies in real time for both powder bed fusion and binder jetting processes. Learn more at www.additivemonitoring.com.