HANOVER and MONHEIM, Germany, Apr 25, 2024 – At the Hannover Messe in Germany, users will be able to get a first glimpse behind the scenes of the upcoming EPLAN Platform 2025. The software, which will be available starting this summer, offers numerous new features for even more ease of use and speed for electrical engineering – with a new macro preview, device-specific properties displays and an expanded Comments Navigator. Users can also expect clever connections for machine cabling as well as terminal strip planning with ClipX Engineer. Specialists in production and service can further expect reduced workloads with innovations for mechanical cable routing as well as QR codes and images on symbols on the schematics.

With the upcoming version of its platform, EPLAN is focussing on making the software even easier and more efficient to use. Faster data availability and more depth of data at key points in the schematics creation process make it possible – for instance in the properties overview, in device management and via QR codes or images directly on symbols in the schematics. Not just electrical engineers, but also control cabinet production specialists and maintenance and service technicians all benefit from the enhancements in the upcoming version.

Easy to use: macro preview in device management

The new EPLAN Platform 2025 supports users with the new macro preview in device management. In addition to the images already supplied in the current version, further device information including the 2D model, the digital twin based on the 3D control cabinet layout and schematics macro are all now available here. Electrical engineers can now see at a glance which data and macros are defined for a motor, as an example, without having to go through the properties. This thus simplifies device management considerably.

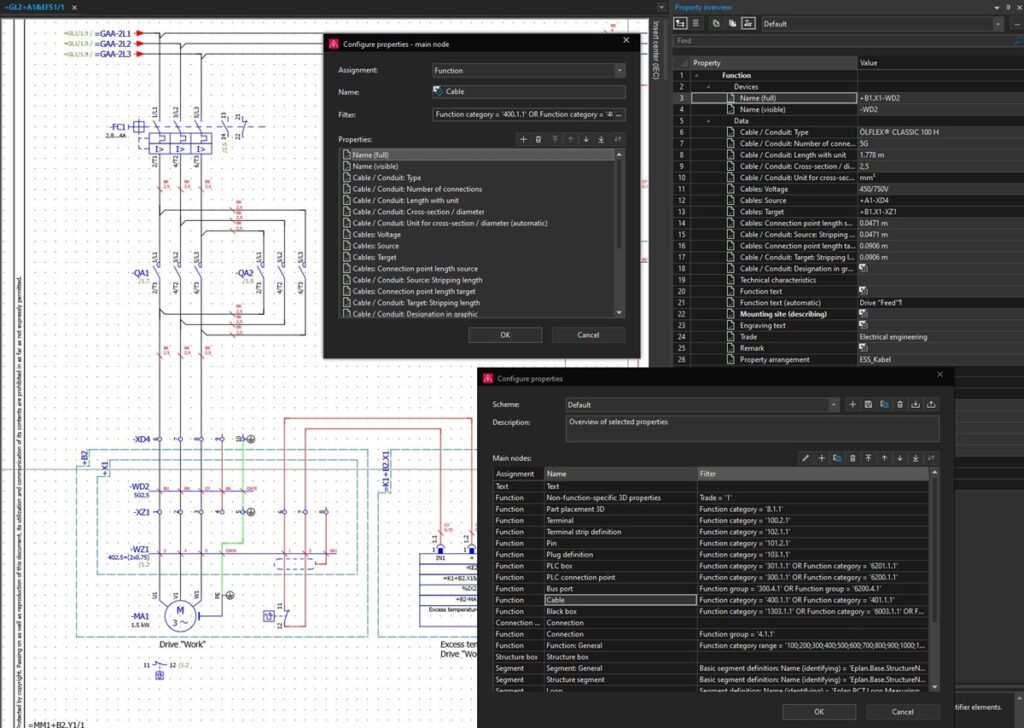

Defined individually: device-specific property display

Users are well aware of the challenge of components such as cables, conductors and terminals all having different properties – including outer diameters, bending radii, cross-sections or the numbers of pins. In EPLAN Version 2025, these device-specific properties are immediately available when a user clicks on the component. Not only does this apply to the properties overview, but will now also be available in device management and the Insert Center. The displayed information is also now fully configurable and can be individually defined for each component type.

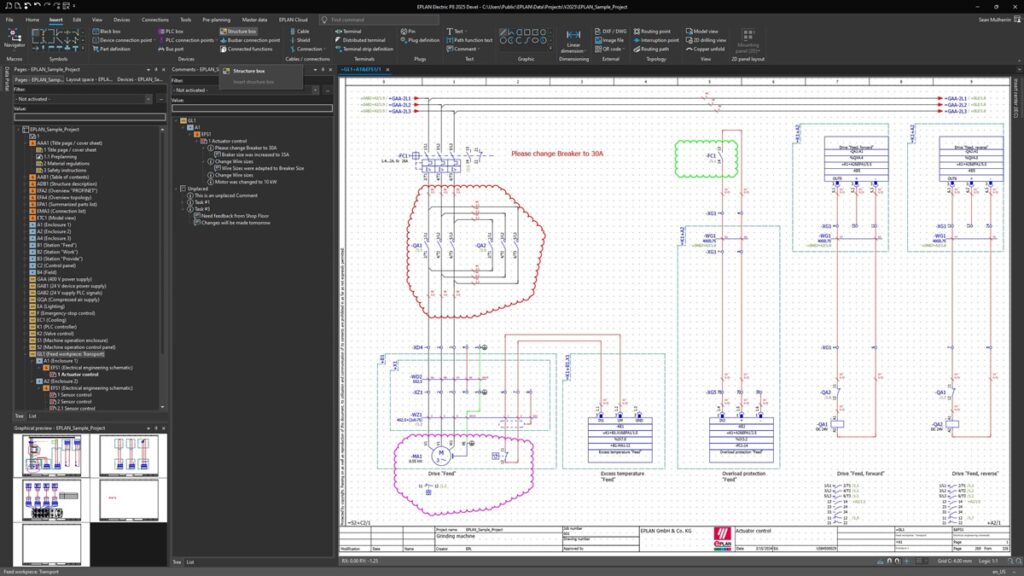

Better collaboration: expanded Comments Navigator

The Comments Navigator will now be directly available in the ribbon menu in the upcoming version. This makes it easier for designers to collaborate and make comments or corrections in the schematics. Users of the collaboration element will also benefit from additional enhancements to the Comments Navigator, where users can create and manage their own comments on the EPLAN Platform, view the history and now also save status information. Cloud-based collaboration – including redlining and greenlining functionality – can also be easily implemented using the EPLAN eVIEW expansion.

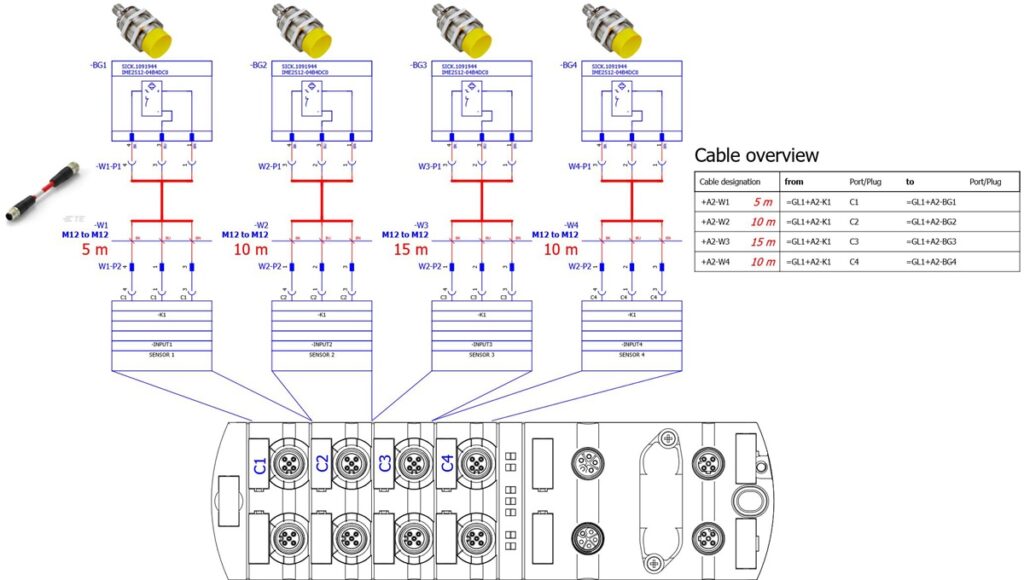

Clever connections: taking machine cabling a step further

Prefabricated cables are often the method of choice for machine cabling. Challenges include the correct definition of such in the schematics, not to mention determining the right lengths for the cables. EPLAN has found an efficient solution to both of these problems in the upcoming version. Machine cabling has reached a new level with the expansions to EPLAN Electric P8 in combination with the new EPLAN Cable proD. The new innovative product EPLAN Cable proD, available this coming summer, serves as the interface between the 3D models from MCAD systems and the correct cabling information from EPLAN Electric P8. Cables can be precisely defined, routed and ordered in the correct lengths.

Perfect planning: straight to the finished terminal strip

Data exchange for control cabinet layouts from EPLAN will soon also be very easy in regards to terminal strips from Phoenix Contact. The new interface to ClipX Engineer enables users to export complete terminal strips from EPLAN Pro Panel to the Phoenix Contact application. ClipX Engineer automatically checks the terminal strips, adds missing or incorrect accessories and then returns the completed terminal strip back to EPLAN Pro Panel. This means that terminal strips, including all the necessary accessories can be easily and correctly planned right from the very start.

Simplifying workloads for production and service: linking QR codes/images with symbols

Users of the EPLAN Platform 2025 can link context-related images or QR codes with symbols and place them directly on the symbols for the first time. By linking the images, they adapt accordingly when changes are made. Furthermore, the QR codes offer much more depth of data: simply scanning them takes users directly to installation instructions or maintenance information. This makes the schematics easier to understand and enables technicians in production, commissioning and servicing to carry out their tasks more quickly.

Easier and faster: mechanical cable routing and feed-through

Dependencies between cables and components, such as current transformers, are automatically displayed in the new version of EPLAN Electric P8 – as part of the EPLAN Platform – and transferred to the connections or cabling lists. This means that time-consuming correction runs due to missing cables can be avoided in production. Mechanical cable feed-through is also available in EPLAN Pro Panel for control cabinet layouts. The software automatically recognises the dependencies between components and cables and routes the cable precisely through the component – without any manual intervention, meaning that no cable can be accidentally forgotten and the connection lists and conductor lists are complete.

About EPLAN

EPLAN provides software and service solutions in the fields of electrical, automation and mechatronic engineering. The company develops one of the world’s leading design software solutions for machine and panel builders. EPLAN is also the ideal partner to streamline challenging engineering processes.

Both standardized as well as customized interfaces to ERP and PLM/PDM systems ensure data consistency along the whole value chain. Working with EPLAN means boundless communication across all engineering disciplines. No matter whether small or large enterprises: Customers can apply their expertise more efficiently. Worldwide, EPLAN supports more than 65,000 customers. EPLAN wants to grow further with customers and partners and pushes integration and automation in engineering forward. Within the EPLAN Partner Network, open interfaces and seamless integrations are realized together with partners. “Efficient engineering” is the focus.

EPLAN was founded in 1984 and is part of the owner-operated Friedhelm Loh Group. The Friedhelm Loh Group operates worldwide with more than 12 production sites and over 95 international subsidiaries. The entire group employs more than 12.000 people and generated revenues of €3 billion in 2022. For the 14th time in succession, the family business has won the accolade “Top German Employer” in 2022. In addition, Friedhelm Loh Group was recognized as “Top vocational trainer” according to a study of Deutschland Test and Focus Money. For more information visit www.eplan-software.com and www.friedhelm-loh-group.com.