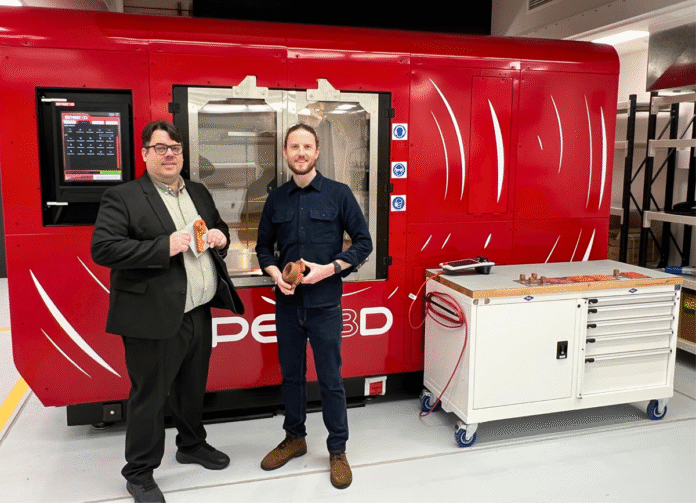

MELBOURNE, Australia, Aug 21, 2025 – SPEE3D, a leading global additive manufacturing company, is pleased to announce the installation of its WarpSPEE3D metal 3D printers at the University of Sydney’s Sydney Manufacturing Hub (SMH). It will be a fresh technology for SMH’s world-leading Large-Format Additive Manufacturing Lab, supporting novel research in Cold Spray Additive Manufacturing (CSAM) and enabling collaborative projects with industry partners.

“The WarpSPEE3D will significantly enhance our capability to pioneer research in Cold Spray Additive Manufacturing, offering an opportunity to collaborate between academia and various industries. This technology provides a platform to experiment, innovate, and bridge the gap between cutting-edge research and real-world applications.” commented, Bruce McLean, Chief Engineer, Sydney Manufacturing Hub.

The WarpSPEE3D will be the latest addition to the Large-Format Additive Manufacturing Lab, where it will be accessible to researchers from the University of Sydney, other academic institutions, and industry collaborators to advance material science. The printer’s highly flexible system supports open experimentation across a diverse range of metal powders—including copper, aluminium, stainless steel, and copper nickel alloys—enabling the development and testing of new materials for unique, industry-relevant applications. This capability positions the University of Sydney as a leader in cold spray additive manufacturing research, fostering rapid prototyping and accelerating material breakthroughs for both established and emerging sectors.

“We are thrilled to partner with the University of Sydney and see WarpSPEE3D become an integral part of their Manufacturing Hub. This collaboration marks an exciting step forward in advancing cold spray application research. Together, we can pave the way for innovative solutions to address the needs of local and national industries to drive practical outcomes.” commented, Steven Camilleri, CTO, SPEE3D.

Recognized for its scalability and cost-effectiveness, the WarpSPEE3D printer utilizes our proprietary Cold Spray Additive Manufacturing (CSAM) technology to produce high-density metal parts at supersonic speeds unrivalled by traditional manufacturing methods. It can create components weighing up to 40kg, with dimensions of 1m by 0.7m in diameter, and with metallurgical properties superior to casting. This innovative process helps significantly reduce project timelines across various industries, delivering durable, ready-to-use metal parts in hours instead of weeks.

About University of Sydney

As Australia’s first university – founded in 1850 – the University of Sydney has been sharing knowledge, empowering students and addressing the world’s most complex challenges for 175 years. Currently ranked first in Australia (US News) and joint 25th in the world (QS World University Rankings), they’re consistently placed among the best universities and globally renowned for their teaching and research.

The Sydney Manufacturing Hub (SMH), a Core Research Facility within the University of Sydney, is a state-of-the-art research facility focused on the development and application of advanced manufacturing techniques. SMH provides a collaborative environment where academic researchers, industry professionals, and innovators work side by side to accelerate technological progress and translate cutting-edge research into practical solutions. Specialising in areas such as additive manufacturing, materials science, and industrial design, SMH plays a critical role in advancing Australia’s manufacturing capabilities and supporting local industries through innovation, workforce development, and impactful projects.

About SPEE3D:

SPEE3D is a leading metal additive manufacturing technology company dedicated to the research, development, and delivery of metal 3D printers and integrated systems utilizing its patented Cold Spray Additive Manufacturing (CSAM) technology. As a result, SPEE3D’s product portfolio enables significantly faster production than traditional metal manufacturing for a wide range of metals, including Copper, Aluminium, Stainless Steel, Aluminium Bronze, and now, Nickel Aluminium Bronze Expeditionary.