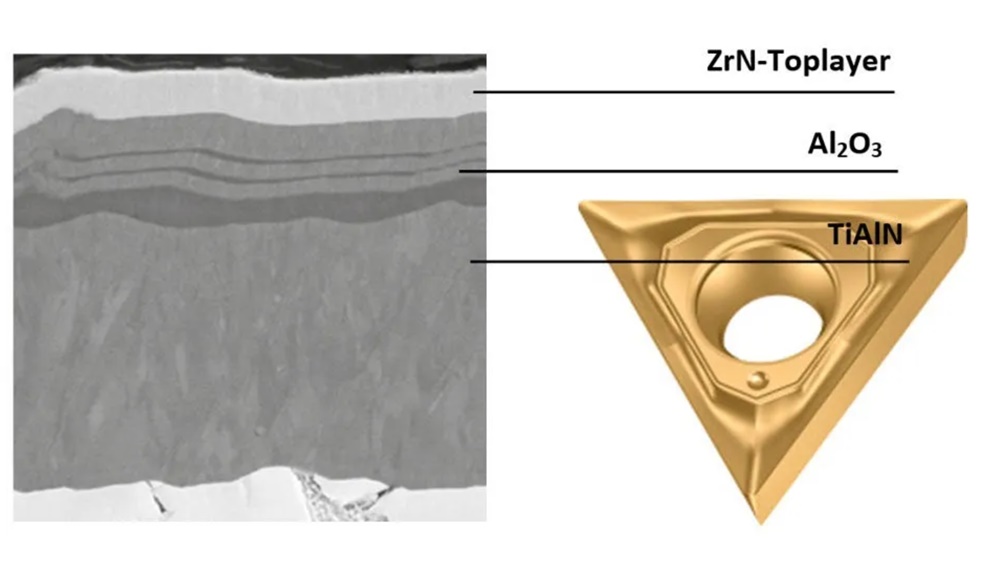

TUBINGEN, Germany, Feb 7, 2024 – Walter’s Tiger·tec Gold WSM37G grade marks a technological leap into a new field of application. For the first time, users will be able to benefit from the advantages of innovative coating technology in thread milling. Like the proven Tiger·tec Gold milling grades, the new grade, whose layer structure is unique on the market and consists of a carbide substrate, wear-resistant TiAlN layer and multi-layer aluminium oxide layer (Al2O3), is also notable for its superior temperature resistance. The finishing touch is the eponymous gold-coloured ZrN top layer. This reduces friction and indicates any wear. Walter cites significantly higher cutting parameters and longer tool edge life as user advantages. In some tests, the grade increased tool life by up to 100%, with far fewer radius corrections. The grade offers maximum productivity when used in conjunction with multi-row thread milling cutters.

With the Tiger·tec Gold WSM37G grade, Walter is setting a new benchmark in the production of standard-compliant blind-hole and through-hole threads: Compatible with all Walter thread milling cutters and can be used universally with all ISO materials: P, M, K, N, S and H up to 55 HRC, from a nominal diameter of 16 mm or UNC¾. The indexable inserts combine chip breakers specially developed for thread milling with two proven geometries: The universal D67 for maximum tool life quantity, and the D61 with anti-vibration land, which guarantees excellent operational smoothness even in difficult conditions (e.g with long projection lengths). Walter’s new Tiger·tec Gold WSM37G grade further demonstrates the company’s innovation prowess in thread milling technology.

About Walter

For over 100 years, Walter has stood for competence and quality in the field of machining technology. The company was founded in 1919 by Richard Walter and has its headquarters in Tübingen, Germany. The portfolio includes precision tools for milling, turning, grooving, drilling and threading as well as individual special tools and technology solutions along the process chain. With production facilities in North and South America, Europe and Asia, numerous subsidiaries and sales partners, and 4,400 employees worldwide, Walter has a global presence and customers in more than 80 countries around the world. In addition to engineering expertise, a sustainable corporate strategy and a diversity approach are part of the corporate culture. Since 2022, the Frezite Group has been part of Walter, including the Frezite portfolio brand FMT, which deals with cutting tools for lightweight materials. For more information, visit https://www.walter-tools.com.