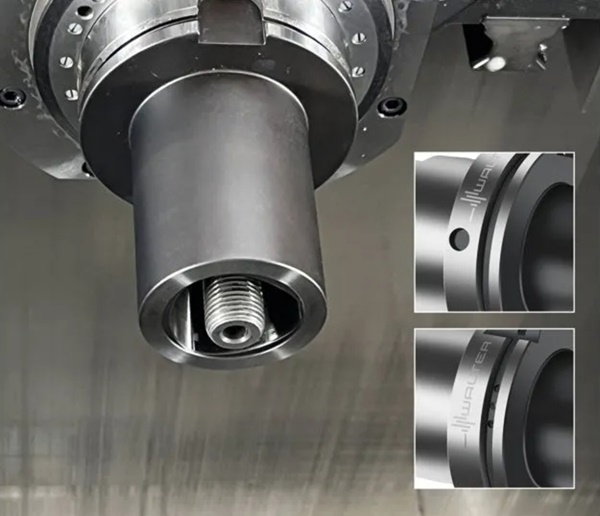

TUBINGEN, Germany, Mar 16, 2024 – By upgrading its master adaptor from HSK to Walter Capto, premium tool manufacturer Walter is launching a state-of-the-art system interface: With concealed balancing holes (which were previously on the outside of the tool), a balanced construction created at the factory and a chip hole which is also made at the factory. The user no longer has to drill this hole themselves and it gives them the possibility of digital tool integration, for example for the purpose of automated tool management.

This is because tool data such as dimensions or the like can be saved by inserting a data chip into the tool itself and can be read out as when required, e.g. for programming or storage. The Tübingen-based company offers the modular adaptor (HA06-C… and HA10-C…) from HSK-A to Walter Capto™ with HSK-A 63 or HSK-A 100 interface in Capto sizes C3–C8.

The manufacturer explains that users will benefit, firstly, from the high level of process reliability and precision because the adaptor is very rigid and, secondly, from the precise repeat accuracy during tool changes (down to 2 µm). What’s more, its incredible versatility must be highlighted. It is suitable for all types of adaptors (such as Weldon, ER collets, hydraulic expansion chucks or milling adaptors with arbor), for milling and holemaking, and for use with all kinds of machines (e.g. machining centres or multi-task machines). Users of data storage devices can open up their entire range of tools with the master adaptor. This is because, not only can it be used with all machines and machining operations, it is also suitable for universal use with all projection lengths – i.e. extensions and reducers. Walter’s master upgrade therefore also embodies many years of experience and Engineering Kompetenz in the field of Capto.

About Walter

For over 100 years, Walter has stood for competence and quality in the field of machining technology. The company was founded in 1919 by Richard Walter and has its headquarters in Tübingen, Germany. The portfolio includes precision tools for milling, turning, grooving, drilling and threading as well as individual special tools and technology solutions along the process chain. With production facilities in North and South America, Europe and Asia, numerous subsidiaries and sales partners, and 4,400 employees worldwide, Walter has a global presence and customers in more than 80 countries around the world. In addition to engineering expertise, a sustainable corporate strategy and a diversity approach are part of the corporate culture. Since 2022, the Frezite Group has been part of Walter, including the Frezite portfolio brand FMT, which deals with cutting tools for lightweight materials. For more information, visit https://www.walter-tools.com.