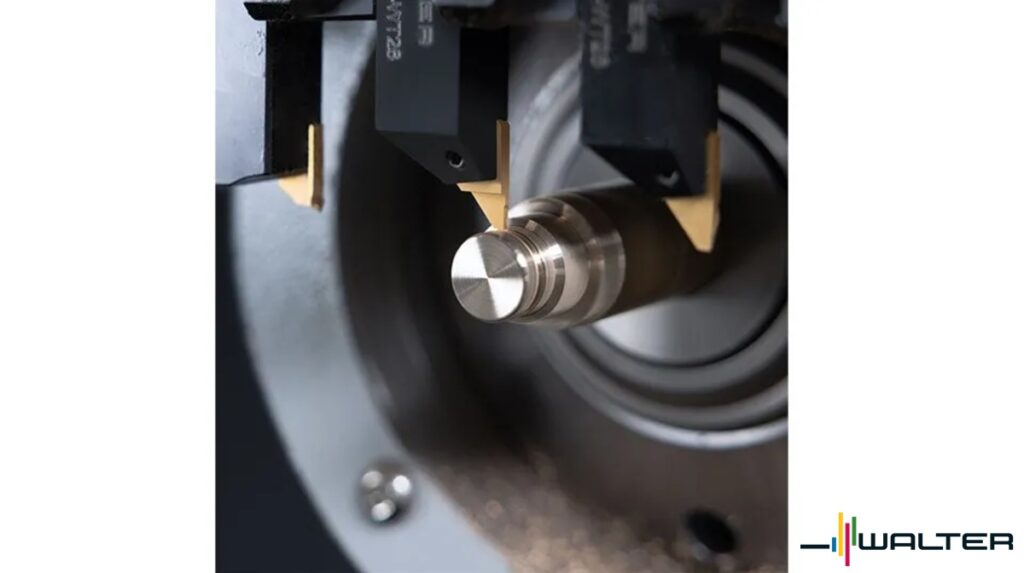

TUBINGEN, Germany, Sep 24, 2024 – With the new double-edged WT26 indexable inserts and the compatible turning toolholder system, Walter offers a solution specifically for producing small parts on sliding-head (Swiss turning) lathes. Bars with a diameter of < 20 mm are preferably machined, resulting in strict requirements for precision. The dovetail shape of the insert clamp is excellent at absorbing lateral forces, ensuring high stability, process reliability and accuracy. The clamp and the large contact surface in the insert seat maximize stability – particularly to counteract vibration of the bar material. Another special feature is the possibility of operation on both sides. The reason? The clamping screw has a Torx on both the head side and the threaded side, meaning that it can always be operated from the side of the counter-spindle on right and left tools. This makes it possible to index the inserts quickly without removing the toolholder, significantly reducing non-productive time.

The tangentially mounted WT26 indexable inserts are precision-ground and boast sharp cutting edges specifically for turning small precision parts. And that’s not all – periphery ground chip breaker geometries are also available (DG8, VG8). These make it possible to achieve optimum machining results even at low feeds (from f: 0.03 mm). Walter’s WT26 indexable inserts come in seven different versions which cover all turning operations – from basic recesses and external threads through to reverse turning with specially developed chip breakers. The new WSM23X cutting tool material is perfect for machining steels, stainless materials and lead-free brass, while the uncoated WN23 grade is suitable for aluminum and non-ferrous metals. What’s more, the cutting inserts can be used in any WT26 toolholder, regardless of the system. This makes the system the ideal solution for mass production of small precision parts like pneumatic valves or small electric motors, like those used in window regulators.

About Walter

For over 100 years, Walter has stood for competence and quality in the field of machining technology. The company was founded in 1919 by Richard Walter and has its headquarters in Tübingen, Germany. The portfolio includes precision tools for milling, turning, grooving, drilling and threading as well as individual special tools and technology solutions along the process chain. With production facilities in North and South America, Europe and Asia, numerous subsidiaries and sales partners, and 4,400 employees worldwide, Walter has a global presence and customers in more than 80 countries around the world. In addition to engineering expertise, a sustainable corporate strategy and a diversity approach are part of the corporate culture. Since 2022, the Frezite Group has been part of Walter, including the Frezite portfolio brand FMT, which deals with cutting tools for lightweight materials. For more information, visit https://www.walter-tools.com.