CHICAGO, IL, USA, Feb 8, 2024 – Wilson Sporting Goods Co. today announces the release of the Wilson Airless Gen1 – the innovative, first-of-its-kind 3D-printed basketball that never needs to be inflated. Building off the success of the Airless Prototype debut last year, the limited-edition Wilson Airless Gen1 basketball will be available for purchase on Feb. 16.

“We were overwhelmed by the excitement from our Airless Prototype, and we knew it was time to bring this rare, first-of-its kind innovation to the world. Wilson has gone where no brand has gone before with the release of the Airless Gen1 basketball, further inspiring the next generation of sports innovation.”

Kevin Murphy, General Manager, Team Sports at Wilson

The Wilson Airless Gen1 has similar functionality to the prototype, however over the last year, the Wilson Labs team has taken the steps to increase performance and streamline the manufacturing process. The basketball nearly fits the performance specifications of a regulation basketball, including its weight, size and rebound (bounce). While the Wilson Airless Gen1 is crafted for play, it is truly a coveted, technology-infused product meant to create and inspire a new community of innovation enthusiasts and basketball hype curators alike.

The main updates to the Wilson Airless Gen1 include:

- Improved functionality: Upgraded lattice design for more consistent performance and bounce. The ball still includes the same see-through lattice with eight panel-like “lobes.”

- Streamlined manufacturing: Holes integrated within the channels to help speed up the manufacturing process, making it faster to create each ball. The basketball remains airless and does not to be inflated.

- Enhanced customization: Each ball will have a built-in label for customization and will feature the exact, limited number in which it was produced.

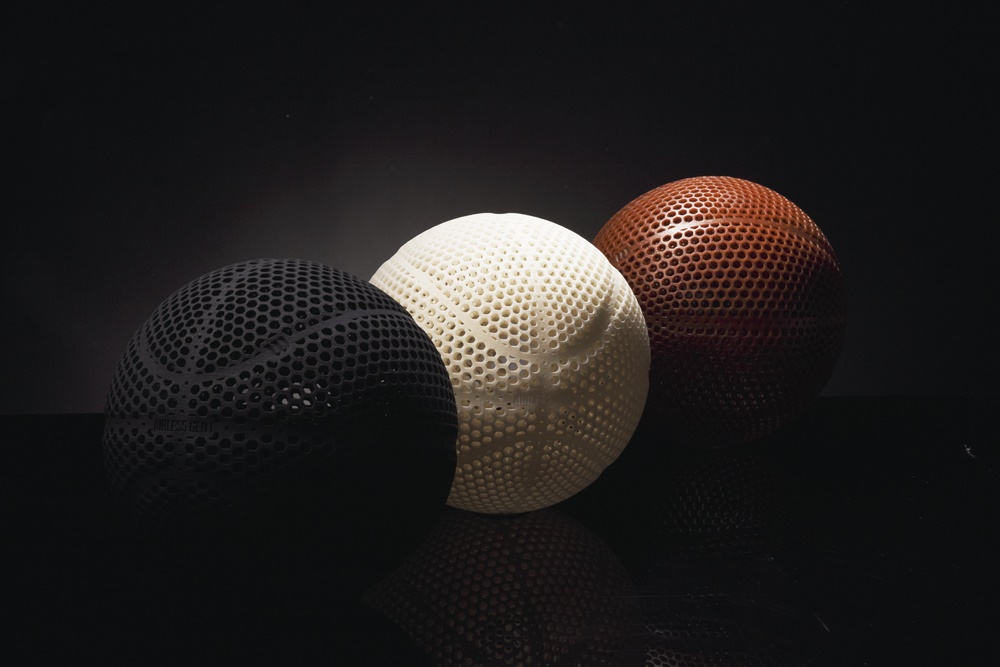

- Color variety: In addition to the recognizable jet-black colorway of the prototype, the Airless Gen1 will also be available in brown and natural white.

Wilson Airless Gen1

The Wilson Labs team leveraged the same game-changing process to create the Wilson Gen1 Airless basketball with key partners: General Lattice provided computational design services for elevated performance optimization, DyeMansion provided color and finishing solutions, EOS provided technical oversight and a roadmap for mass production, while SNL Creative was the primary manufacturing hub for this first launch.

Availability

Limited units of the Wilson Airless Gen1 will be available exclusively on Wilson.com beginning Friday, Feb. 16 for $2,500. Fans can also experience the product at Wilson’s on-site activation at NBA Crossover in Indianapolis from Feb. 16 – 18. To learn more, please visit Wilson.com and follow along @wilson and @wilsonbasketball.

About Wilson Sporting Goods Co.

Chicago, USA-based Wilson Sporting Goods Co., part of Amer Sports Corporation, is the world’s leading manufacturer of high-performance sports equipment, apparel, footwear and accessories. The Company brings more than a century of innovation, history and heritage across many sports including Racquet Sports, Baseball, Softball, American Football, Basketball, Volleyball, Soccer and Golf.

In Basketball, Wilson is the supplier of Official Game Basketballs for the National Basketball Association® (NBA), the Women’s National Basketball Association® (WNBA), National Collegiate Athletic Association® (NCAA) for March Madness and the Final Four, Basketball Champions League (BCL), Basketball Africa League (BAL) and FIBA 3×3.

For more information, visit www.wilson.com.

About EOS

EOS provides responsible manufacturing solutions via industrial 3D printing technology to manufacturers around the world. Connecting high quality production efficiency with its pioneering innovation and sustainable practices, the independent company formed in 1989 will shape the future of manufacturing. Powered by its platform-driven digital value network of machines and a holistic portfolio of services, materials and processes, EOS is deeply committed to fulfilling its customers’ needs and acting responsibly for our planet. For more information, visit https://www.eos.info.

About General Lattice

As a leader in the additive manufacturing space, General Lattice delivers end-to-end computational design and digital manufacturing solutions on a service and software basis. The company is headquartered in Chicago, IL. To learn more about General Lattice, Inc., visit www.generallattice.com or contact info@generallattice.com. Follow the company on Instagram @generallattice.

About SNL Creative

SNL Creative stands at the forefront of additive manufacturing, offering cutting-edge 3D printing solutions and rapid prototyping services. The new facility in Cypress, CA, embodies the company’s dedication to pushing boundaries, embracing innovation, and ensuring client satisfaction through advanced technology and expert teams. For more information, visit https://snlcreative.com.

About DyeMansion

DyeMansion is the global leader in post-processing solutions for industrial polymer 3D-printing that turns 3D-printed raw parts into high-value products. From perfect fit eyewear to personalized car interiors, their technology makes 3D-printed products become a part of our everyday life. Starting in 2015 with the first industrial coloring solution for powder bed fusion parts, the Munich-based company extended its portfolio with advanced part cleaning and surfacing solutions for a wider range of 3D-printing technologies in the field of plastics. Today, DyeMansion’s Print-to-Product workflow combines industry-leading hardware with the widest range of color and surfacing options on the market. Their systems are applicable for Industry 4.0 and can be integrated seamlessly into various production processes. The ability to provide a flexible solution for both small batches and high volumes makes DyeMansion a trusted partner for future factories. Through close collaboration with customers across all industries, the 3D-finishing technology and expertise continuously grow with the market. Reduced cost per part, unmatched quality, and high sustainability are core values that drive each innovation of the fast-growing company. In addition to these principles, finding the right finish for every application is what drives them. Learn more about DyeMansion and visit www.dyemansion.com, LinkedIn, Instagram, twitter or YouTube.