HANGZHOU, China, Sep 22, 2025 — Scanology is proud to announce the launch of NimProbe, a next-generation compact optical 3D probing system designed to bring unmatched flexibility, accuracy, and mobility to industrial inspection and smart manufacturing.

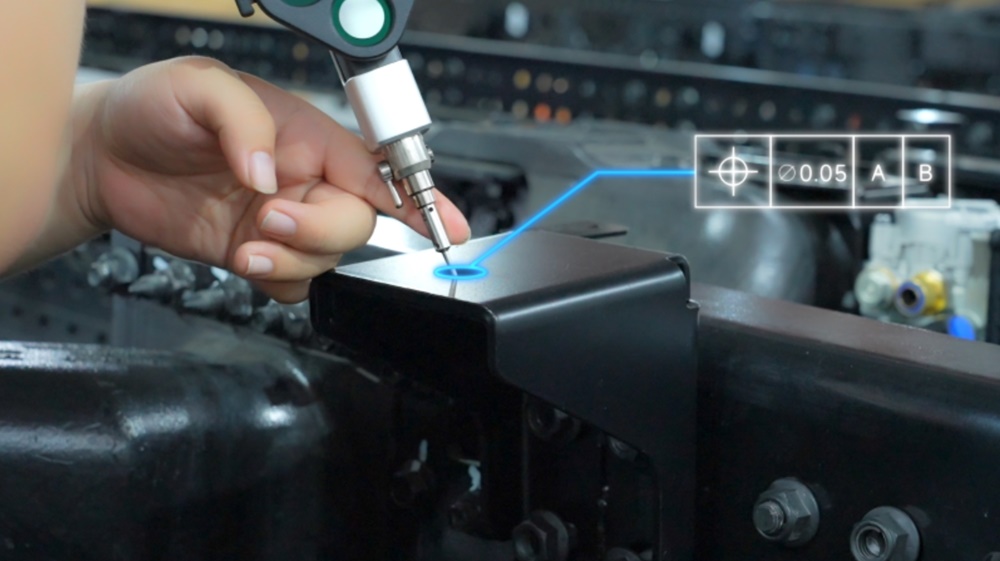

NimProbe combines the handheld i-Probe with the i-Tracker in a fully wireless, lightweight design, redefining high-precision measurement for small-to-medium parts. By merging probing and scanning into one innovative solution, it empowers manufacturers to streamline workflows, enhance quality control, and achieve faster, more reliable results.

All-in-One, Ready Anywhere

Portable and lightweight, NimProbe transforms into a mobile measurement station in just one minute. Packed into a single case for easy transport, it is built for workshops, production lines, and even outdoor environments. The i-Probe weighs just 700 g, making it effortless to use without fatigue.

Probing Meets Scanning

Breaking away from the limitations of traditional systems, NimProbe enables seamless switching between probing and handheld laser scanning. The i-Tracker doubles as a powerful 3D scanner, capturing precise point clouds, while DefinSight software integrates probing and scanning data in real time. The result: a smarter, faster, and more versatile inspection solution that adapts to any industrial task.

Extensive and Precise Measurement

With the i-Tracker’s large field of view, the i-Probe achieves measurement distances of up to 4.2 meters in a single setup. It delivers metrology-grade volumetric accuracy of 0.072 mm at 4.2 meters and 0.059 mm at 3.5 meters.

Equipped with advanced sensors and algorithms, NimProbe ensures accurate capture of geometric features and GD&T, making it ideal for precision parts in automotive, aerospace, and heavy industries.

Probing Without Limits

Designed for real-world challenges, the i-Probe—with its 500-mm probe length—reaches into reference holes, hidden points, and complex geometries. An intelligent occlusion compensation algorithm guarantees accuracy even when markers are partially blocked, enabling reliable inspection of irregular parts, pipelines, and hard-to-reach features.

Stay Mobile, Stay Precise

Within the tracker’s field of view, the probe moves freely while being tracked in real time. Whether switching positions, probing from multiple angles, or inspecting along dynamic production lines, NimProbe delivers efficient results with minimal setup time.

Flexible Connectivity, Maximum Reliability

NimProbe supports both wireless and wired modes:

Wireless: Maximum flexibility, free from cable restrictions.

Wired: Stable performance with secure data transmission.

Versatile for Every Application

Engineered for diverse industrial environments, NimProbe withstands vibration, temperature shifts, humidity, and variable lighting. Its dynamic compensation algorithms ensure accuracy and stability in any setting.

With a wide range of stylus and corner extension rods, NimProbe adapts to intricate curved surfaces, deep cavities, and large precision parts. Whether in fixture verification, benchmark marking, or dimensional inspection, NimProbe consistently delivers reliable, high-precision measurements that drive modern intelligent manufacturing forward.

About SCANOLOGY

SCANOLOGY is a global provider of comprehensive 3D solutions. We specialize in R&D, production, and sales of 3D scanners and 3D systems and boast a long history of developing hardware and software. We offer two main product categories: industrial high-precision 3D scanners and professional, cost-effective 3D scanners, including portable 3D scanners, tracking 3D scanners, industrial automated 3D systems, and professional color 3D scanners. For more information, visit https://www.3d-scantech.com.