GibbsCAM 2026: Next-Generation Engine Redefines Advanced 3D Machining

(Thousand Oaks, CA, 2025/09/30)

GibbsCAM, a leading CAD/CAM innovator in the production machining industry, releases its latest version, marking a milestone in CAM innovation. The highlight is the new Advanced 3D Machining engine, delivering faster calculation times, more efficient toolpaths, and improved surface quality. Alongside this significant achievement, GibbsCAM 2026 continues to enhance usability with a more intuitive user interface, a new GibbsCAM Viewer for company-wide data access, and improvements in Variable-B Turning. Additional upgrades strengthen multi-axis machining, tool management, and simulation capabilities, underscoring GibbsCAM’s position as a leader in CNC programming for high-end cutting technologies.

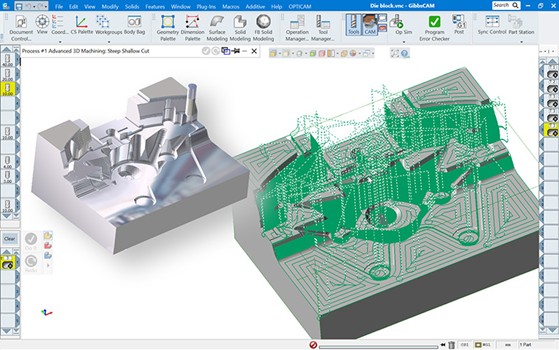

A New Era for Advanced 3D Machining

At the heart of GibbsCAM 2026 lies a completely re-engineered Advanced 3D Machining Engine. This new core delivers significant gains in toolpath generation speed, ensuring faster programming cycles and fewer iterations. It produces smoother, more predictable toolpaths, leading to superior surface finishes and a reduced need for secondary finishing. Despite the major architectural shift, the familiar GibbsCAM interface remains unchanged, allowing users to benefit immediately without requiring retraining.

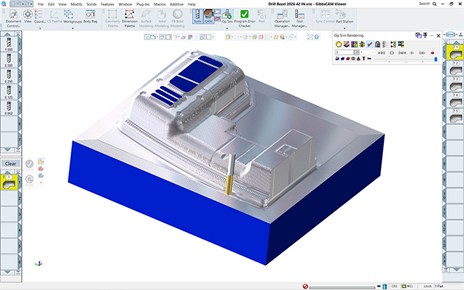

GibbsCAM Viewer – Access for the Entire Enterprise

With GibbsCAM Viewer, organizations gain the ability to review, inspect, and communicate CAM data anywhere in the company—without risk of altering toolpaths or NC code. Operators, managers, and quality teams can visualize parts, verify geometry, analyze toolpaths, and generate reports using the same familiar interface. This tool streamlines communication and helps reduce errors while keeping programming data secure. Machinists can now run parts with greater confidence and knowledge of what to expect.

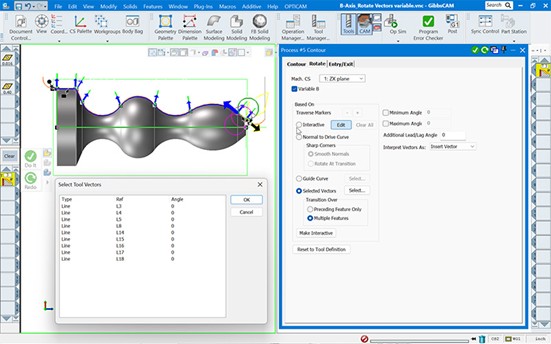

Advancements in Turning and MTM Programming

GibbsCAM 2026 significantly enhances Variable-B Turning with a more intuitive, interactive workflow. Programmers can define tool angles directly along the cut path using control points, with smooth interpolation for precise control over complex operations. This makes Variable-B Turning more flexible and easier to use, reducing setup effort while improving accuracy.

For Multi-Sided Turning tools such as Sandvik Coromant’s CoroTurn® Prime inserts, toolpath generation is now smarter and more efficient. The system calculates material engagement intelligently, maximizing insert geometry while maintaining safety. The result is improved material removal, consistent operation, and greater efficiency in advanced turning tasks.

Smarter Tool Management

GibbsCAM 2026 introduces the new Tool Usage Reporter, offering precise, operation-based tracking of all tools. Accessible directly from the Tool dialog, this manager-style interface displays every operation that uses a selected tool, with intuitive row selection, workspace highlighting, and direct access to operation controls. Users can quickly identify, select, or remove tool-linked operations, making tool management faster and more transparent.

The release also brings a redesigned, spreadsheet-style Tool List View, providing a clear, column-labeled layout for reviewing and editing tools. Both the standard and list views now include filtering by tool group, enabling users to isolate and manage specific sets of tools easily. Together, these enhancements simplify tool organization, improve workflow efficiency, and give programmers better oversight of tool usage in complex projects.

Expanding Multi-Axis and 5-Axis Capabilities

GibbsCAM 2026 further refines multi-axis machining with advanced tilting strategies, improved AutoTilt functionality, and smarter toolpath orientation to reduce unnecessary machine movement. The AutoTilt feature now supports bullnose tools, increasing versatility. Two new strategies, Tilted into Plane and Tilt Tool in a User-defined Plane, provide programmers with precise control over tool axis orientation, aligning tilt with specific rotational axes for more stable and efficient machining. The enhanced automatic tilting kernel ensures consistent results across existing toolpaths, simplifying the adoption of the latest features.

Multiblade machining also sees significant improvements. The new Edge Finishing strategy delivers high-quality surface results while protecting delicate leading edges, and expanded tool support now includes flat end mills, bullnose mills, and taper tools. Users can customize feed rates for links, lead-ins, lead-outs, and edge extensions, reducing non-cutting time and optimizing cycle efficiency.

Additional upgrades include enhanced wall finishing, improved rotary machining finishing, and more effective deburring, giving operators greater control, speed, and precision across complex multi-axis operations.

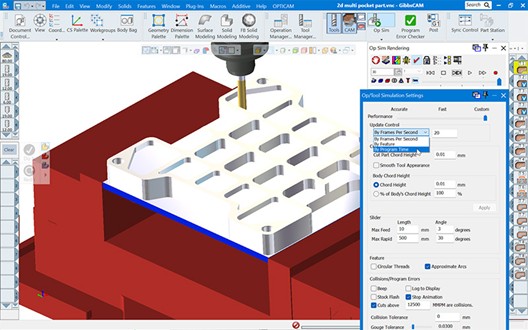

GibbsCAM 2026 Offers Even More

GibbsCAM 2026 has even more to offer, with a broad range of usability and simulation enhancements that streamline programming and improve workflow clarity. Users can now scale solids, sheets, and facet bodies with precision, rotate geometry out of plane without complex workarounds, and measure minimum and maximum distances for improved part inspection. Stock definitions are more accurate, thanks to improvements like cylindrical Shrink Wrap, while Undo/Redo history navigation provides quick access to any point in the design process. Simulation playback reflects actual machining time and includes metallic rendering options for enhanced visual clarity. Together, these upgrades make GibbsCAM 2026 faster, more intuitive, and more reliable for complex machining operations.

Stronger Portfolio with New Partner Solutions

Over the past few weeks, GibbsCAM has expanded its portfolio with various new partner technologies that enhance performance and automation capabilities. VERICUT® Optimizer for GibbsCAM dynamically adjusts feed rates to maintain ideal chip thickness. The result: 15 to 30% faster cycle times, longer tool life, and consistent cutting quality, without changing proven GibbsCAM toolpaths.

ToolManageriQ™ provides centralized management of tools, holders, and fixtures through a robust SQL database. Fully integrated with GibbsCAM and available in a standalone version, it eliminates duplicated work, improves collaboration, and ensures reliable access to accurate tool data across the organization.

Launching alongside GibbsCAM 2026, CloudNC CAM Assist for GibbsCAM introduces cloud-based AI automation for CNC programming. The system can generate complete 3-axis and 3+2 toolpaths directly from GibbsCAM session data, dramatically reducing programming time and helping companies address the shortage of experienced programmers.

Thorsten Strauß, President of GibbsCAM, about the new release:

“With GibbsCAM 2026, we are taking another important step forward in delivering best-in-class solutions and services to our customers worldwide. I am proud of the dedication and expertise our team has demonstrated in bringing this release to life, and I am excited about the opportunities it creates for manufacturers. The new Advanced 3D Machining engine, combined with our continued focus on usability and intelligent automation, represents not only a major achievement today but also a strong foundation for the future of CAM. We are committed to supporting our customers on their journey to more efficient, reliable, and innovative manufacturing.”

About GibbsCAM

GibbsCAM®, part of Sandvik Manufacturing Solutions, has been shaping intelligent manufacturing for over 40 years. Known for its unrivaled strengths in Multi-Task Machining (MTM) and Swiss-style programming, GibbsCAM continues to deliver cutting-edge solutions with seamless integration of Sandvik Coromant’s innovative turning technologies. By combining deep engineering expertise with a commitment to sustainability and intelligent automation, GibbsCAM enables manufacturers worldwide to achieve greater efficiency, precision, and competitiveness. GibbsCAM integrates with all major CAD systems and supports 2 to 5-axis milling, turning, Swiss machining, multi-task machining (MTM), and Wire EDM. GibbsCAM is a part of Sandvik Manufacturing Solutions.

To find out more about GibbsCAM 2026 and the new features, visit our website: https://www.gibbscam.com/en/whats-new