BARLASSINA, Italy, Feb 20, 2026 – With the AIMIS-LFAM project, Caracol and the European Space Agency explore how artificial intelligence and robotic LFAM can enable autonomous manufacturing in orbit, unlocking a new era for space infrastructure.

The future of space exploration is no longer limited to launching fully assembled structures from Earth. As missions grow in scale and complexity, the ability to manufacture directly in orbit is emerging as a strategic game changer. Producing large structures – such as trusses, solar array supports, and deployable systems – directly in space allows engineers to overcome launch constraints, reduce mass, and unlock design solutions that would be impossible to transport from Earth.

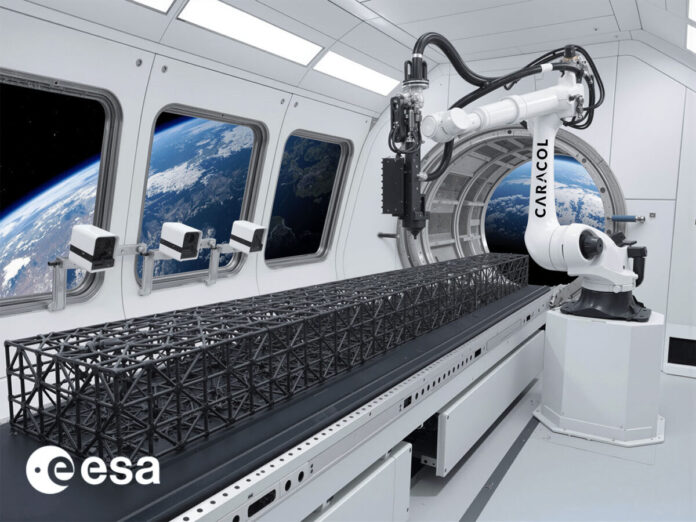

This vision lies at the core of the AIMIS-LFAM project (AI-Based Monitoring of Large Robotic Format Additive Manufacturing in Space), developed under the European Space Agency – Technology Development & De-Risking program. As Prime Contractor, Caracol led the initiative, coordinating a consortium that also included Politecnico di Milano and OBO Space, reinforcing its position as one of Europe’s most advanced players in robotic large-format additive manufacturing. The nine-month project directly supports ESA strategic frameworks such as the Technology Vision 2040 and the SOLARIS initiative, which promote sustainable, autonomous, and resilient space infrastructure.

From terrestrial LFAM to autonomous manufacturing in orbit

Manufacturing in space is fundamentally different from manufacturing on Earth. Microgravity, vacuum, extreme temperature gradients, and radiation can significantly affect material behavior and process stability. At the same time, human supervision is limited or entirely absent, making traditional quality control approaches impractical. For robotic LFAM to become a viable solution for in-space applications, the process must be autonomous, intelligent, and self-aware; capable of monitoring itself, detecting defects, and ensuring reliability in real time. Leveraging its deep expertise in robotic extrusion, LFAM, and advanced manufacturing systems, Caracol developed an AI-driven, multi-sensor monitoring architecture specifically designed for its large-scale robotic 3D printing technology, Heron AM.

Within the AIMIS-LFAM project, visible and infrared sensors were integrated into Heron AM to capture both geometric and thermal data during the printing process. These data streams were then processed using artificial intelligence algorithms trained to identify anomalies such as thermal instabilities and material irregularities during material deposition. Politecnico di Milano contributed its scientific expertise in data analysis, artificial intelligence, and process modelling, supporting the development of advanced monitoring algorithms and data fusion strategies. OBO Space complemented the consortium with its aerospace engineering know-how, providing insight into space environment constraints, system integration, and mission-oriented requirements.

On-Earth experimental trials demonstrated that combining multi-sensor data with AI-based analysis enables early and accurate defect detection, significantly improving process stability. Over the project duration, the monitoring system was successfully advanced from TRL 2 to TRL 3. In parallel, a structured Development Plan was defined to guide future activities toward TRL 4–6, through extended testing and prototype demonstration in representative environments.

From technology validation to orbital manufacturing

AIMIS-LFAM confirms that AI-enabled monitoring is a key enabler for autonomous manufacturing in space: by combining advanced artificial intelligence with Heron AM, Caracol has demonstrated outstanding system integration capabilities and deep process expertise, delivering a robust foundation for reliable in-space LFAM. The project aligns with ESA’s long-term vision for sustainable and self-reliant space infrastructure, opening the door to future applications such as space-based solar power systems, large deployable structures, and orbital manufacturing platforms.

Building on these results, Caracol is uniquely positioned to lead the next generation of in-space manufacturing projects. Future developments will focus on advancing Heron AM toward higher Technology Readiness Levels, with prototype validation in vacuum and microgravity environments and the expansion toward full-scale autonomous orbital manufacturing. With AIMIS-LFAM, Caracol is not simply adapting manufacturing for space, it is defining how large structures will be built directly in orbit, shaping the industrial future of space.

About Caracol

Caracol was founded in 2017 in Milan, Italy, with the vision of pushing the limits of additive manufacturing in terms of scale, efficiency, and sustainability. The company accomplished this by developing an integrated technological platform, including both hardware and software, to produce advanced large-scale components. Through the integration of a patented extrusion head, the development of dedicated software – Eidos Manufacturing, and the use of robotic arms as movement support, Caracol offers an additive manufacturing technology for advanced components for customers in industries such as aerospace, marine, energy, design, and architecture. Heron AM manufactures parts such as jigs and molds for aircraft components, finished parts for yacht and boat superstructures, or revolutionary projects to initiate virtuous circular economy processes for the energy or design sectors. Vipra AM is the latest launched LFAM system to produce large-scale metal applications in the most demanding industries such as aerospace, energy, construction and shipbuilding. Today, the company has opened the largest LFAM production center in Europe, a production facility in Austin (TX), USA opened in August 2023, and a commercial office in Dubai, has a core team of over 80 international professionals with highly specialized competences, in areas such as mechanical engineering, automation, computational design, design for additive, and advanced manufacturing processes.

For more information, visit www.caracol-am.com.