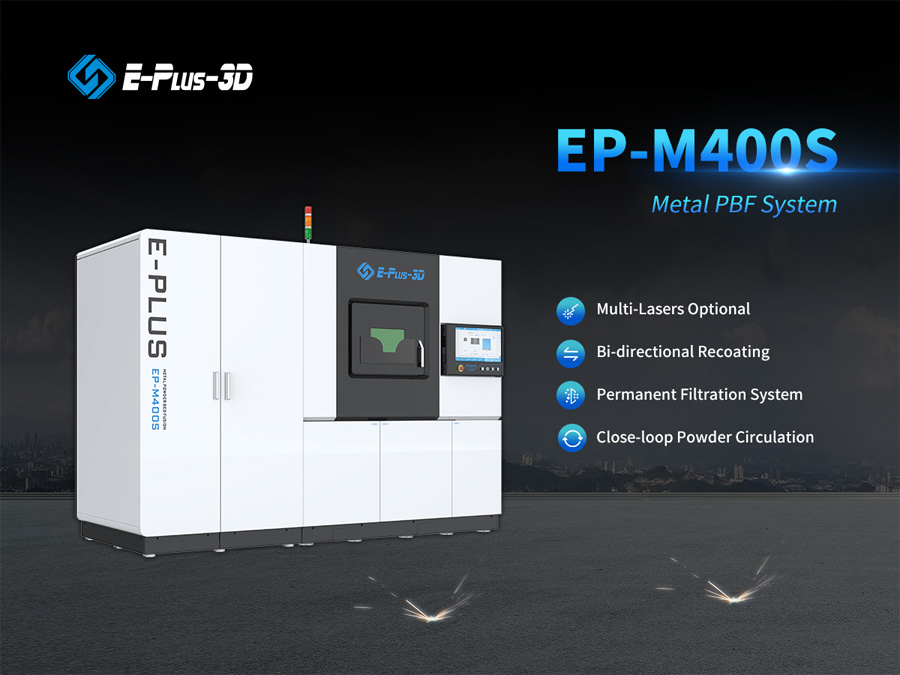

HANGZHOU, China, Feb 13, 2024 – Eplus3D, one of leading additive manufacturing innovators, proudly introduces the EP-M400S, the latest addition to its advanced lineup of metal additive manufacturing machines. Building upon the success of the EP-M400, this new model brings significant enhancements to fortify the flexibility and performance of Eplus3D mid-size systems.

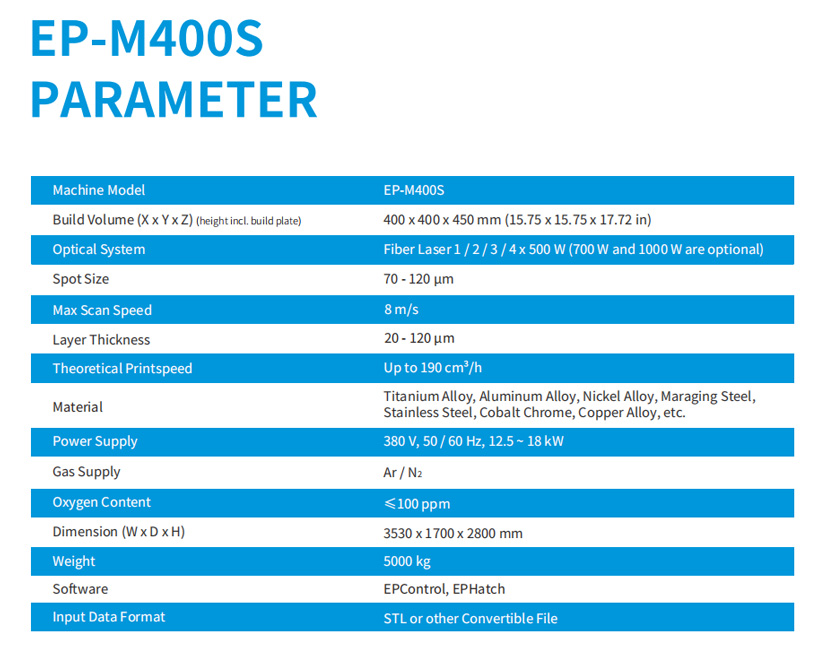

The laser configuration of the EP-M400S is a highlight, offering an exceptional level of customization. With options for 1, 2, 3 and 4 lasers with multiple power levels (500W, 700W, and 1KW for each laser), users can fine-tune the performance to meet the specific demands of diverse applications. Combining the expertise and technology of our large and small frame systems with the 4 different efficiency modes available in the EP Control software, doing this with a combination of recoating speed and laser assignment strategy, to allow for application specific optimization in the running of the print jobs.

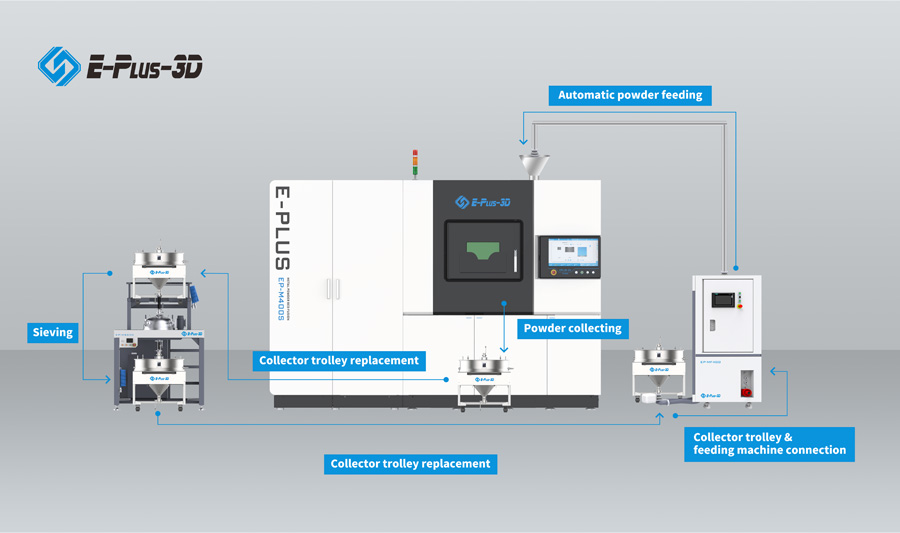

A major innovation in the EP-M400S is the adoption of top feeding powder hopper and Bi-directional powder re-coating, reducing dosing time by up to 30%. This innovative approach significantly streamlines the metal powder layering process, leading to substantial time savings, making the EP-M400S a more efficient system for close-loop powder circulation.

Fully compatible with accessories such as our ultrasonic sieving machine EP-MS600 and Automated powder feeding system EP-MF400. The EP-M400S facilitates seamless integration and unlocks the ability to refill the powder tank without interrupting the printing process, saving valuable time, and preserving powder conditions within an inert atmosphere.

With the design change, the EP-M400S undergoes a size reduction of 10% from its previous specification giving high level of accuracy and reliability in a smaller package. Features added to the new construction will also provide easier access into cleaning and maintenance locations on the machine, not only improving the functionality but also the serviceability of the machine.

Retaining the layer thickness and material compatibility of its predecessor, the EP-M400S finds applications across diverse industries, including Aerospace, Automotive, Molding, and Medical Implants. Its adaptability positions it as an all-encompassing metal 3D printing solution, enriching its value and utility.

Eplus3D’s EP-M400S stands as a testament to the company’s unwavering commitment to pioneering advancements in metal additive manufacturing, propelling industries forward with cutting-edge solutions that redefine the possibilities of industrial production.

About Eplus3D

Founded in 2014, Eplus3D has now developed into one of the world’s leading providers of complete solutions in the field of metal additive manufacturing. With more than 80 systems in Europe, particularly in the aerospace, medical and mechanical engineering sectors, the company has extensive expertise in its core markets.

The dedicated team of engineers in Ludwigsburg near Stuttgart offers customer support in German, English, Spanish, French and Arabic. The goal of Eplus3D is to support customers in metal 3D printing through the innovation center with extensive machine equipment and a warehouse for consumables and spare parts. In this way, the company enables rapid success and economic growth for its customers.

Eplus3D is a reliable partner for high-quality metal 3D printing that is valued worldwide. For more information, visit https://www.eplus3d.com.