MILAN, Italy, Oct 13, 2025 – Hexagon, a global leader in measurement technologies for manufacturing and industrial applications, is promoting digital transformation initiatives at its Moncalieri and Grugliasco plants in Piedmont in the north of Italy. These initiatives are part of an ongoing development plan to enhance production efficiency, optimize resource use and advance environmental sustainability.

Energy digital twin for production efficiency at Grugliasco

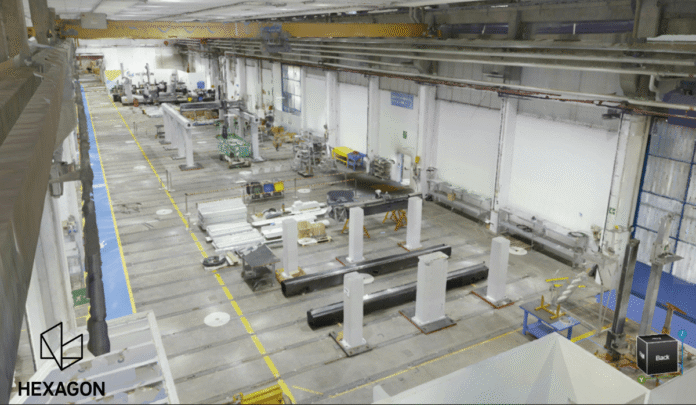

At the Grugliasco plant, Hexagon’s headquarters in Italy and the production centre of measuring machines, work is underway to develop an energy Digital Twin combining two strategic goals: digitalization and energy efficiency.

In the first phase, Hexagon’s Leica 3D scanning technology captured a dense point cloud of the environment to create a detailed three-dimensional model of the facility. This 3D Digital Factory model proved crucial for the spatial analysis and planning, enabling optimal machine layout and early identification of any structural constraints, such as protruding pillars or non-compliant heights, that could compromise the installation of new equipment.

Innovation in production processes at Moncalieri

The Moncalieri plant, which specializes in machining , has focused on reducing waste through multiple initiatives:

The introduction of LED lighting and other energy efficiency measures at both plants has reduced emissions by 250 tCO2e, representing 52% of the overall reduction potential. The reconfiguration of heating systems and better insulation have further reduced gas consumption compared to the 2013-2019 average, down 37% at Grugliasco, and 6.5% at Moncalieri, cutting an additional 130 tCO₂e and 7 tCO₂e respectively.

Digitalization initiatives have also reduced paper use, saving around 4 tonnes of CO₂ annually. And throughout 2025, newly installed photovoltaic panels will supply 44% of electricity needs, based on 2023 consumption levels.

Together, these measures reduce emissions equivalent to the annual carbon footprint of more than 100 Italian residents.

These initiatives form part of Hexagon’s global factory efficiency programme, a concrete commitment to leading the ecological and digital transition of manufacturing through advanced, sustainable technological solutions.

“We are very proud of the results achieved to date at our plants in Moncalieri and Grugliasco,” said Luca Ruggiero, Managing Director of Sales at Hexagon’s Manufacturing Intelligence division in Italy, “These projects are key elements of our global vision and demonstrate how technological innovation and energy efficiency can converge to deliver value for both business and the environment. They are a concrete example of how it is possible to achieve tangible results in terms of sustainability without compromising business competitiveness.”

“We firmly believe in the manufacturing sector’s potential to drive the transition to a more sustainable future,” added Fabrizio Pescetto, Managing Director of Manufacturing at Hexagon’s Manufacturing Intelligence division in Italy. “Our Italian plants exemplify our ongoing commitment to reducing waste and embracing renewable energy sources.”

About Hexagon

Hexagon is the global leader in measurement technologies. We provide the confidence that vital industries rely on to build, navigate, and innovate. From microns to Mars, our solutions ensure productivity, quality, safety, and sustainability in everything from manufacturing and construction to mining and autonomous systems.

Hexagon (Nasdaq Stockholm: HEXA B) has approximately 24,800 employees in 50 countries and net sales of approximately 5.4bn EUR. Learn more at hexagon.com.