MUNICH, Germany and WESTFORD, MA, USA, May 12, 2025 – Zuken, a global leader in electronic design automation (EDA) solutions, has announced the release of the 2025 updates to its flagship PCB design applications, CR-8000 Design Gateway and Design Force. This latest version introduces targeted enhancements to improve design integrity, accelerate schematic and layout development, and address the growing complexity of high-speed, high-density electronics.

The engineering front end, CR-8000 Design Gateway, delivers major advancements in schematic design, including intelligent auto-generation of connectors and standard circuits. Engineers can now quickly populate schematics with predefined blocks—such as filters and ESD protection—based on signal-aware rules, while intelligent rule-based checks and automated validation tools assess component lifespan, thermal margins, and voltage stability, ensuring design integrity from the earliest stages.

On the physical layout side, CR-8000 Design Force introduces delay-aware routing and AI-assisted features that streamline tasks like bus completion and decoupling capacitor placement, ensuring timing compliance and reducing manual effort. Collectively, these enhancements accelerate development cycles, improve design consistency, and support first-pass success in advanced PCB designs.

“With the 2025 release, we’ve focused on taking the pressure off engineers—whether they’re racing to meet timing margins or cleaning up schematics. The new automation features in Design Gateway make it easier to get reliable circuits in place without all the repetitive work, and Design Force keeps high-speed routing tight and efficient. It’s all about getting to a clean, manufacturable board faster—with fewer headaches along the way,” said Francesco De Cet, Head of Business, Zuken Europe.

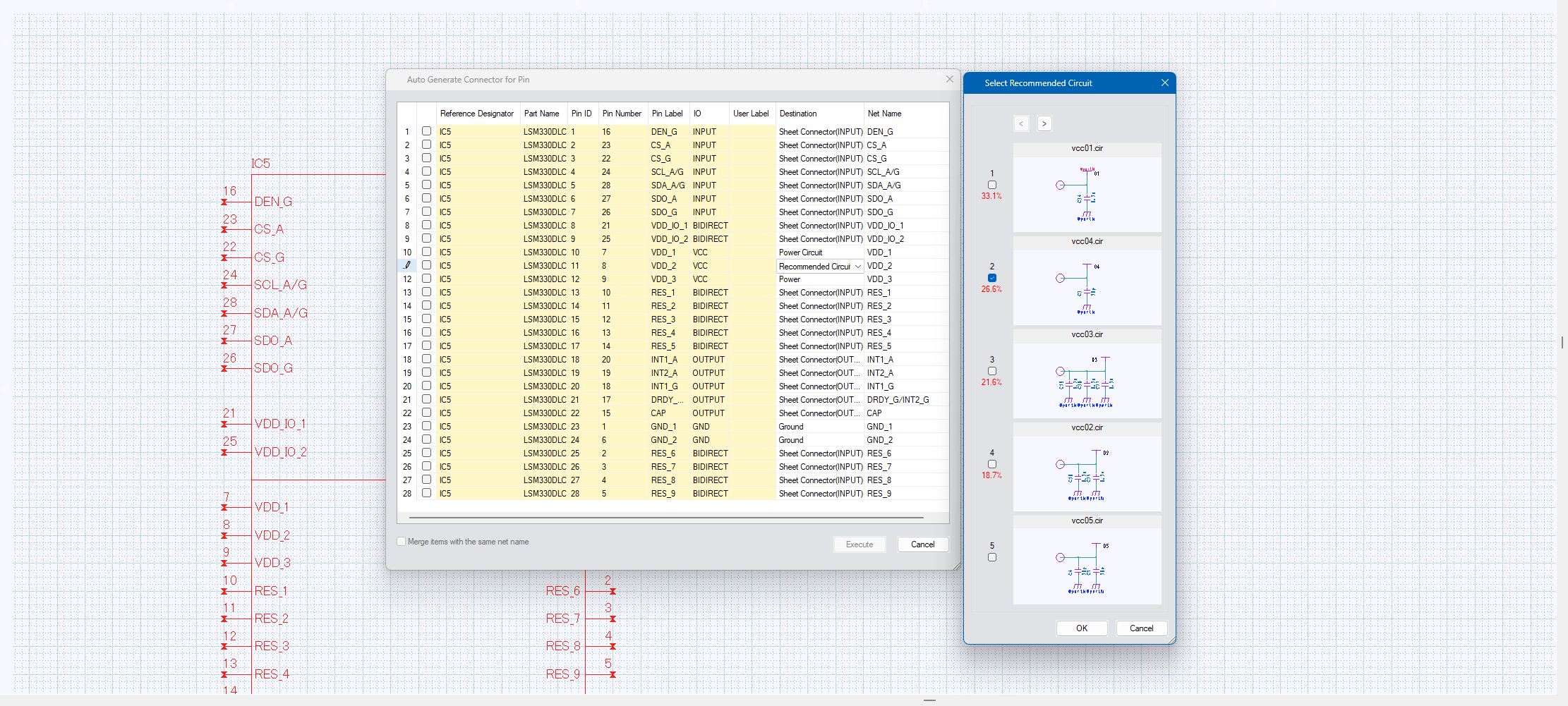

Accelerating Schematic Design with Intelligent Auto-Generation of Connectors and Standard Circuits

In the engineering front end Design Gateway, CR-8000 2025 introduces powerful enhancements in Automated Circuit Generation, significantly advancing early-stage design automation. Engineers can now auto-generate connectors for unconnected pins and deploy standardized circuit blocks—such as RC filters, pull-up/down networks, or ESD protection—based on signal and part attributes. Leveraging a configurable rule engine and machine-learning-style recommendations, this feature reduces manual schematic creation, ensures design consistency, and accelerates schematic development. Additionally, intuitive simulation feedback directly within the design context enables immediate validation of voltage levels, net integrity, and rule compliance, allowing engineers to catch issues early and refine designs on the fly.

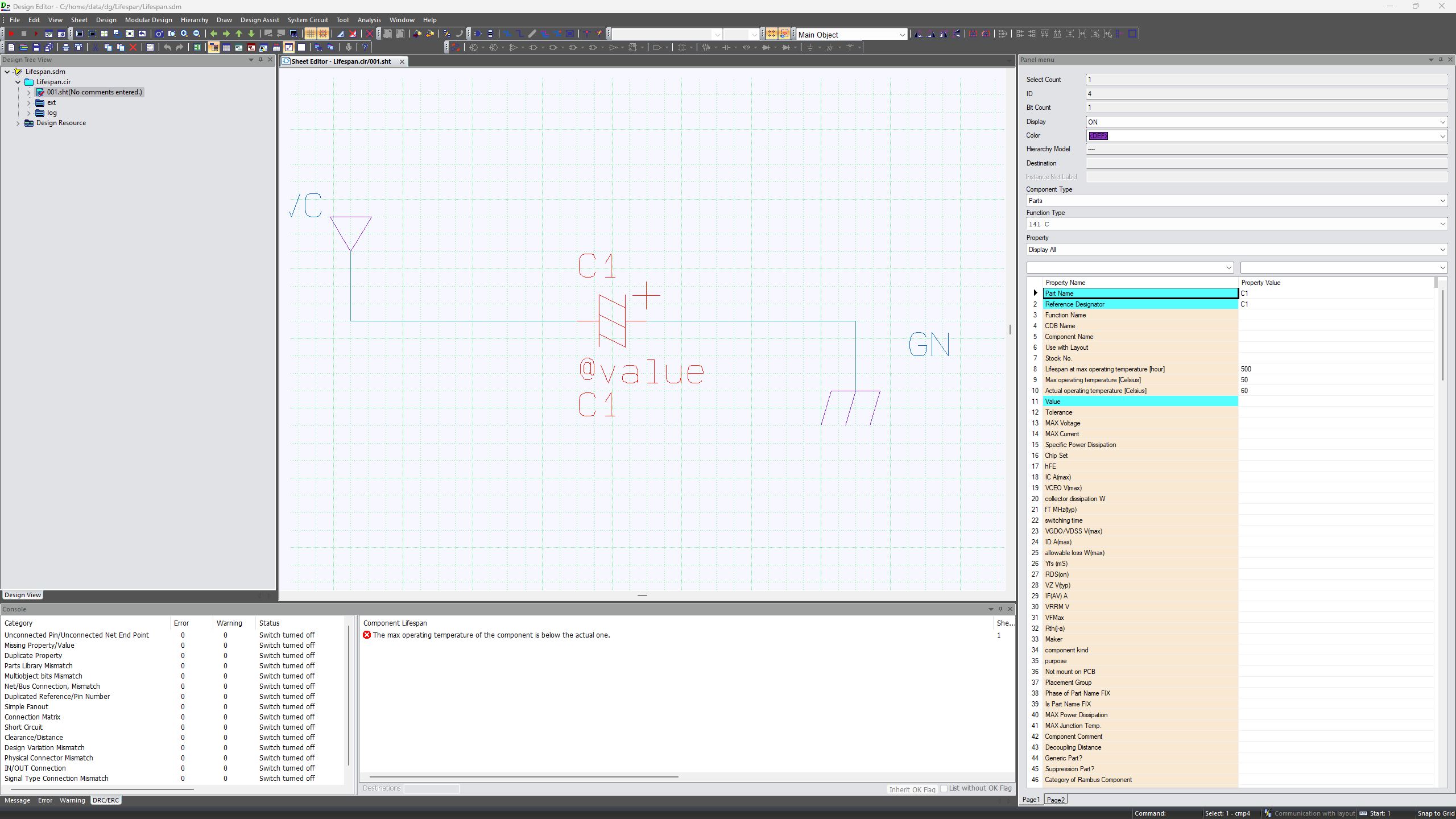

Automated Reliability Checks with a Rule-Based Verification Engine

Circuit Adviser, the intelligent rule-based verification engine within CR-8000 Design Gateway, has been significantly enhanced in the 2025 release to support advanced reliability analysis. It now offers automated checks for early detection of design risks, including detailed thermal and electrical validation. Key enhancements include component lifespan verification against the expected product lifecycle, thermal checks to automatically identify components operating near or beyond safe limits, and an improved Power IC analysis that evaluates voltage margins and power dissipation. These capabilities enable engineers to proactively uncover potential failure points early in the design process, reducing field issues and minimizing costly late-stage redesigns.

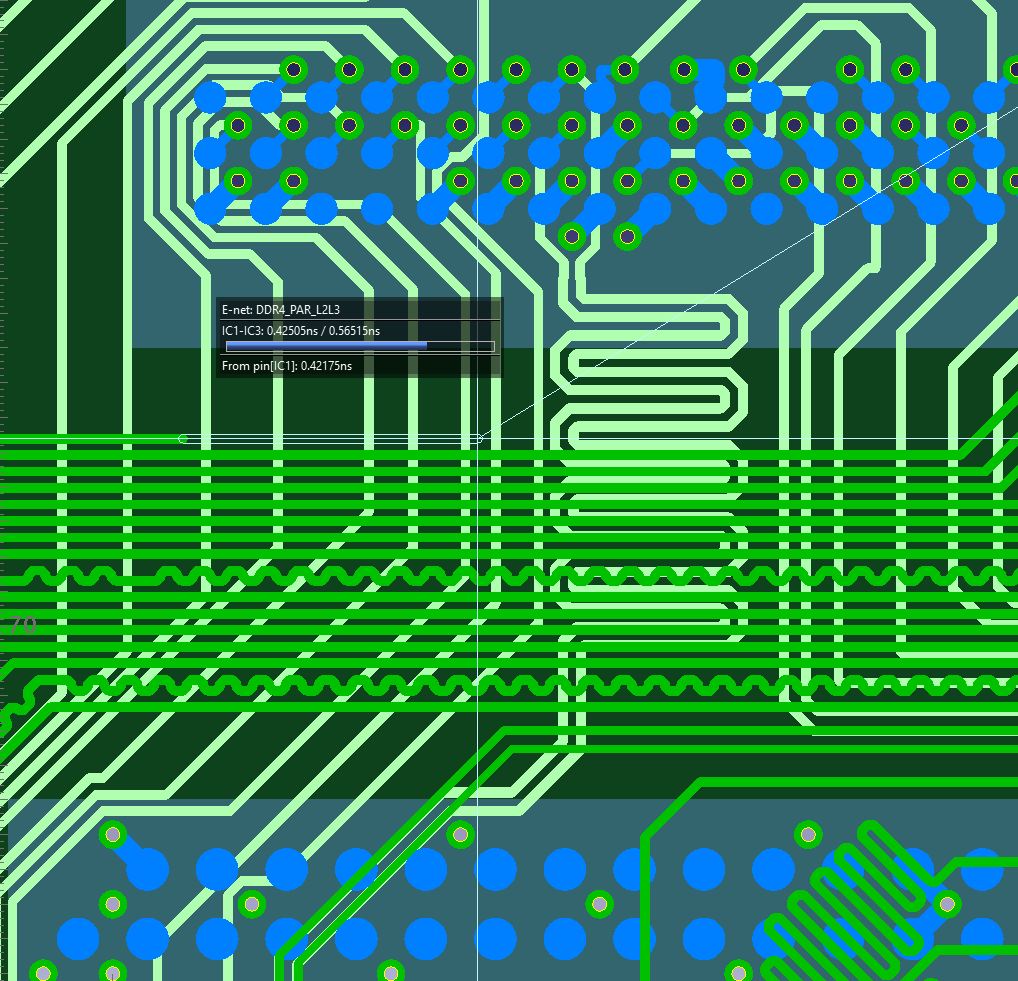

Delay-Aware Routing and Intelligent, AI-Enhanced Automation

CR-8000 Design Force enhances high-speed PCB layout with delay-aware routing tools such as real-time routing balloons, skew visualization, and topology-driven guidance. These help engineers meet timing constraints for interfaces like DDR4 and PCIe with precision, reducing guesswork and eliminating the need for repeated verification cycles. Complementing this, intelligent AI-enhanced automation accelerates layout by automating decoupling capacitor placement, completing bus routes, and generating standard connection circuits. These tools support the designer without replacing them—improving efficiency, reducing rework, and enabling a modular path toward increasingly autonomous design.

Together, these capabilities improve first-pass success rates and significantly reduce overall design cycle time.

Release Date and Availability

The CR-8000 2025 release is now available to customers through Zuken’s Global Support portal, and to qualified prospects via guided evaluations and interactive demonstrations. For new customers, trial access and expert-led sessions—such as Zuken’s Experience Days—provide hands-on exposure to the latest features. Additional product information, including a detailed overview of enhancements and demo requests, is available on the Zuken website or through regional representatives.

For more information about CR-8000 Release 2025 and other Zuken solutions, please visit the CR-8000 section on Zuken.com.

About CR-8000

CR-8000 is Zuken’s integrated 3D PCB design and analysis platform, supporting the complete electronic product development lifecycle. Its core applications—System Planner, Design Gateway, Design Force, and DFM Center—cover the full spectrum of PCB subsystem design, including system architecture, multi-board layout, IC packaging, digital twin modeling, connected manufacturing, and advanced signal and power integrity analysis. Uniquely, CR-8000 combines these capabilities with robust engineering data management, offering integrated library control, design reuse, change tracking, and seamless PLM and supply chain integration.

About Zuken

Zuken is a global software company delivering advanced electrical and electronic design solutions. Founded in 1976, the company has built a strong reputation for technology innovation and financial stability in the EDA industry. Its flagship product families—CR-8000 for electronic design and E3.series for electrical systems—offer comprehensive 2D/3D system-level toolsets, backed by robust design data and configuration management capabilities. With its strategic entry into Model-Based Systems Engineering (MBSE), Zuken has embraced digital transformation, integrating MBSE tools and services with its established design platforms to meet the complex development needs of industries worldwide. For more information about the company and its products, visit www.zuken.com, www.zuken.com/blog, or www.linkedin.com/company/zuken