LAKE MARY, FL, USA, Mar 22, 2021 – FARO (Nasdaq: FARO), a global leader of 3D measurement, imaging, and realization solutions for the 3D Metrology, AEC (Architecture, Engineering & Construction), and Public Safety Analytics markets, announces changes to its Board of directors.

The Company is pleased to announce Mr. Jeroen van Rotterdam’s appointment to its Board of Directors.

Mr. van Rotterdam brings a comprehensive background in multiple technologies, including cloud development and security, with nearly 25 years of experience with EMC Corporation, several startups, and most recently, Citrix Systems.

“FARO is uniquely positioned to drive increased long-term shareholder value through its extensive suite of 3D software applications targeting customer solutions in the 3D Metrology, AEC, and Public Safety and Analytic markets. FARO’s ability to capture, analyze and provide 3D data positions it well to increase the value it realizes from its existing 15,000 customers,” stated Board Chairman John Donofrio. “Jeroen’s depth of experience is highly relevant to FARO’s strategy and complementary to our current board composition.”

Mr. van Rotterdam will be included in the Company’s slate of nominees for election to the Board of Directors at the Company’s 2021 annual stockholders meeting.

Board of Director Departures

Effective the date of FARO’s 2021 annual stockholders meeting, Mr. John E. Caldwell will be retiring from the FARO Board and Dr. Jeffrey A. Graves has chosen not to stand for re-election.

“Mr. Caldwell has been a highly effective FARO board member since 2002, providing valued leadership, insights and mentoring throughout his tenure. Dr. Graves was appointed the Chief Executive Officer of 3D Systems in May 2020, and as a result, is limiting his involvement in outside directorships,” stated Mr. Donofrio. “The Company thanks Mr. Caldwell and Dr. Graves for their meaningful contributions. They will be missed.”

“As the Company executes its transformational strategy with an emphasis on software-enabled solutions to drive long-term competitive differentiation and increased customer value, board renewal aligned with FARO’s strategy will continue. We expect to announce further additions to the Board over time,” stated Mr. Donofrio.

About FARO

For 40 years, FARO has provided industry-leading technology solutions that enable customers to measure their world, and then use that data to make smarter decisions faster. FARO continues to be a pioneer in bridging the digital and physical worlds through data-driven reliable accuracy, precision, and immediacy. For more information, visit www.faro.com.

Mendix platform helps enable IT and business to work together collaboratively to build applications needed to run the business.

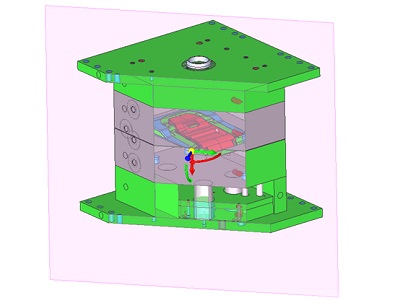

Mendix platform helps enable IT and business to work together collaboratively to build applications needed to run the business. Logopress ProgSim allows for accurate forming simulation of progressive dies based on an incremental approach.

Logopress ProgSim allows for accurate forming simulation of progressive dies based on an incremental approach. Logopress ProgSim provides extremely accurate forming results – much earlier and cheaper than only using the tryout press.

Logopress ProgSim provides extremely accurate forming results – much earlier and cheaper than only using the tryout press.

Helical hobbed, straight gear skived

Helical hobbed, straight gear skived Compact gear shafts – Combined processes

Compact gear shafts – Combined processes EPD Standard Suite for Windows enables the creation of prototypes by allowing designers to skip the schematic process and build their prototype directly as a board design.

EPD Standard Suite for Windows enables the creation of prototypes by allowing designers to skip the schematic process and build their prototype directly as a board design.

Kelsey DeBriyn

Kelsey DeBriyn