PLANO, TX, USA, Jun 22, 2020 – Siemens Digital Industries Software announces an expanded Capital electrical/electronic (E/E) systems development software portfolio. Building upon leading Capital capabilities for design, manufacture and service of electrical systems, the portfolio is now expanded to encompass E/E system and software architectures, network communications and embedded software development. As part of the Xcelerator portfolio of software, services and application development platform, Capital is integrated with adjacent Siemens solutions, including the Teamcenter portfolio for product lifecycle management, NX software for mechanical design and Mendix low code development environments, which creates the world’s most comprehensive E/E systems development solution to efficiently engineer today’s smart products.

Comprehensive Portfolio from Requirements to Validation

Modern E/E systems are characterized by a huge growth in complexity and depend on integrated electrical, electronic and software systems for innovation, while demanding robust verification & traceability. To effectively manage these interconnected challenges, the E/E systems development solution from Capital encompasses E/E systems architecture, electrical systems, communication networks and embedded software. It supports integrated end-to-end model-based design, manufacturing and service domains to transform quality and reduce costs. Strategic integrations with Siemens’ model-based systems engineering (MBSE), MCAD, product lifecycle management (PLM), simulation and manufacturing solutions help enable a comprehensive digital twin of the whole product. These integrations deliver requirements management, multi-domain functional modelling, software simulation, application lifecycle management and manufacturing plant simulation.

“Siemens continues to be on the forefront of bringing together formerly siloed disciplines required to develop and support today’s smart, connected products,” said Craig A. Brown, Executive Consultant, CIMdata. “By integrating Capital with these technologies, Siemens is providing companies a system-wide view of their products allowing them to economically achieve the performance and quality their customers require.”

Customers can address the mega trend challenges that autonomous and electric products bring to the market with model-based engineering solutions. Automotive companies can employ E/E systems development to develop vehicle platforms driven by architectural designs through design implementation, manufacturing and service across the spectrum of electrical and software challenges. Aerospace companies can now take advantage of this architectural-driven approach to minimize program risk and help achieve compliance.

The end-to-end capture and definition of the E/E system functionality enables the creation of a comprehensive digital twin for early simulation and verification. This allows organizations to ‘shift-left’ or move their verification and validation earlier in the product development process, thereby helping achieve faster product development, higher product quality and reduced time to market. The model-based approach of Capital helps enable high levels of automation and data continuity via a digital thread connecting product optimization, realization and certification. As well as supporting an end-to-end flow, Capital is flexible to adapt to specific customer needs, supporting individual ways of working while providing support for necessary industry standards as part of an open ecosystem.

“Over the last two decades the Capital portfolio has been strategically expanded to meet the needs of innovative organizations that are ushering in the future of E/E systems development in industries as diverse as automotive, aerospace, marine and industrial machinery,” stated Martin O’Brien, senior vice president of Siemens’ Integrated Electrical Systems business. “Companies have realized significant tangible benefits when they deploy Capital for the development of electrical systems, networks and embedded software.”

Capital now supports the delivery of more innovative products, while helping increase efficiency and reducing cost from design through manufacturing to service. Siemens continues to drive digital transformation across industries, including automotive, aerospace and defense segments, by providing technology to create and leverage a comprehensive digital twin. For more information on the Capital E/E Systems Development flow, visit: siemens.com/ee-systems.

About Siemens Digital Industries Software

Siemens Digital Industries Software is driving transformation to enable a digital enterprise where engineering, manufacturing and electronics design meet tomorrow. The Xcelerator portfolio helps companies of all sizes create and leverage digital twins that provide organizations with new insights, opportunities and levels of automation to drive innovation. For more information on Siemens Digital Industries Software products and services, visit www.sw.siemens.com or follow us on LinkedIn, Twitter, Facebook and Instagram. Siemens Digital Industries Software – Where today meets tomorrow.

About Siemens Digital Industries

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 76,000 employees internationally.

About Siemens

Siemens AG (Berlin and Munich) is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 170 years. The company is active around the globe, focusing on the areas of power generation and distribution, intelligent infrastructure for buildings and distributed energy systems, and automation and digitalization in the process and manufacturing industries. Through the separately managed company Siemens Mobility, a leading supplier of smart mobility solutions for rail and road transport, Siemens is shaping the world market for passenger and freight services. Due to its majority stakes in the publicly listed companies Siemens Healthineers AG and Siemens Gamesa Renewable Energy, Siemens is also a world-leading supplier of medical technology and digital healthcare services as well as environmentally friendly solutions for onshore and offshore wind power generation. In fiscal 2019, which ended on September 30, 2019, Siemens generated revenue of €86.8 billion and net income of €5.6 billion. At the end of September 2019, the company had around 385,000 employees worldwide. Further information is available on the Internet at www.siemens.com.

Teamcenter X allows companies to easily connect PLM with familiar applications for secure, agile collaboration across the enterprise, and across functional domains.

Teamcenter X allows companies to easily connect PLM with familiar applications for secure, agile collaboration across the enterprise, and across functional domains. NX offers the flexibility of 2D paper concept design within the 3D CAD environment, as the first in the industry to eliminate upfront constraints on the design.

NX offers the flexibility of 2D paper concept design within the 3D CAD environment, as the first in the industry to eliminate upfront constraints on the design.

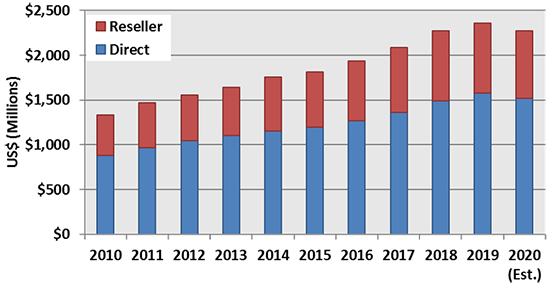

Size and Growth of the CAM Software and Related Services Market Based on End-User Payments

Size and Growth of the CAM Software and Related Services Market Based on End-User Payments