SAN RAFAEL, CA, USA, Jun 1, 2020 – Autodesk, Inc. (NASDAQ: ADSK) announced powerful new integration capabilities for Autodesk Construction Cloud with the release of a new integration platform Autodesk Construction Cloud Connect and an expansion of its partner ecosystem. Autodesk added several new APIs enabling custom connections for BIM 360 and PlanGrid, and 15 new native integrations, bringing the total number of direct integrations in the Autodesk Construction Cloud ecosystem up to over 140. Project teams can now more easily build custom integrations and streamline data across workflows – from design to planning, building and operations – so they can increase efficiency and productivity.

Autodesk Construction Cloud Connect facilitates out-of-the-box integrations

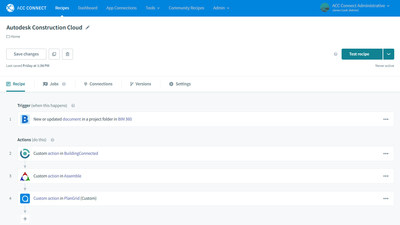

Autodesk Construction Cloud Connect (ACC Connect), an evolution of PlanGrid Connect, is an intuitive, ready-to-use integration platform that allows customers to create flexible integrations without writing code. Powered by Workato, ACC Connect supports integrations for Assemble, BIM 360, BuildingConnected and PlanGrid. Customers can connect their Autodesk Construction Cloud products to automate continuous or scheduled data flows with a wide range of SaaS applications including Box, Smartsheet, DocuSign, and QuickBooks Online.

Autodesk Construction Cloud customers can collaborate on workflows across the building lifecycle, and they may turn to point solutions for specific activities such as file sharing, expense management and time tracking. Instead of dedicating software development resources, which can be costly and challenging to find, to build custom integrations between Autodesk products and these specialized solutions, customers can now rely on ACC Connect to easily configure their own integrations.

“Transferring data between the applications we use and those used by our clients and subcontractor partners can often be a complex, expensive, and error-prone process,” said Blaine Crawford, director of information technology, C.W. Driver. “ACC Connect lets us easily build custom integrations between the solutions used across each of our project teams and workflows so we can streamline our data management, spend more time on project-critical tasks and ultimately drive more productivity.”

New APIs and native integrations provide direct connections to ACC products

Autodesk’s newest APIs also allow both customers and partners to build bidirectional custom integrations with BIM 360 and PlanGrid. Permissions APIs for BIM 360 can automatically ensure collaborators only can access specific project information, and Cost Management APIs allow connections with specialized accounting tools. Partners can leverage PlanGrid’s new Advanced RFI, Submittals and Custom Forms APIs to populate and extract data so customers always see the latest information, regardless of which integrated application they access.

The ecosystem of partners taking advantage of APIs for direct integration to Autodesk Construction Cloud products has also expanded with 15 new additions. The new integrations simplify data management for processes ranging from material tracking to identifying components of a build that can be prefabricated.

Customers using BIM 360 can now leverage integrations with Agileandover, Contecht, Matterport, MSuite, Plannerly, Reconstruct, Shedmate, SignNow; customers using PlanGrid can now leverage integrations with DataStreet, Extracker, FACS, ProjectMates and Zters. Both BIM 360 and PlanGrid now integrate with Allegion Overtur and StructionSite as well.

“The construction industry is increasingly adopting model-driven collaboration across the project lifecycle,” says Britton Langdon, president of MSUITE. “Autodesk is uniquely positioned to provide strong integrations with design files and integrating with Autodesk Construction Cloud enables us to provide our customers the strongest access to their design data throughout preconstruction, fabrication and site construction workflows.”

“Construction projects today involve multiple technology applications serving various team members and workflows,” said Angi Izzi, director of partnerships for Autodesk Construction Solutions. “When those applications can’t talk to each other and data becomes siloed, productivity is compromised across workflows. The expansion of our integration capabilities underscores our commitment to driving construction productivity and empowering the industry to collaborate with deeper connections to technologies and teams.”

More information about ACC Connect and the newest APIs, check out:

About Autodesk

Autodesk makes software for people who make things. If you’ve ever driven a high-performance car, admired a towering skyscraper, used a smartphone, or watched a great film, chances are you’ve experienced what millions of Autodesk customers are doing with our software. Autodesk gives you the power to make anything. For more information visit https://www.autodesk.com or follow @autodesk.

CAD models of metal 3D Printed cricket feeder for Cincinnati Zoo

CAD models of metal 3D Printed cricket feeder for Cincinnati Zoo Inside the metal 3D printed cricket feeder. Device installed at the Discovery Rainforest at Cincinnati Zoo

Inside the metal 3D printed cricket feeder. Device installed at the Discovery Rainforest at Cincinnati Zoo Animals at Cincinnati Zoo engaging with the metal 3D printed cricket feeders.

Animals at Cincinnati Zoo engaging with the metal 3D printed cricket feeders. AlibreCAM using the new display engine in AD v21 Same part displayed using the legacy display

AlibreCAM using the new display engine in AD v21 Same part displayed using the legacy display