LONDON, UK, May 20, 2020 – Schneider Electric, the leader in digital transformation of energy management and automation, and AVEVA, the global leader in engineering and industrial software, today announced their expanded partnership to deliver innovative solutions for the data center market.

As hyperscale providers build data centers with an expanding fleet to meet worldwide demand, the complexities to operate and maintain these facilities are creating an unprecedented set of challenges. Operating at this scale requires a different approach for mission critical facilities powering the globe’s digital infrastructure. The combination of AVEVA™ Unified Operations Center, scalable industrial software with Schneider Electric’s EcoStruxure for Data Centers control and monitoring capabilities enables both deep and expansive visibility to day-to-day operations.

The new joint solutions provide a homogenous view of engineering, operations, and performance across a heterogenous, legacy installed base. Hyperscale data center providers will benefit from this partnership by connecting platforms and data sets that previously existed in disparate systems. They will also be able to scale regardless of number of sites or global location. Data center staff will be empowered to make faster, more informed decisions and optimize asset and operational efficiency throughout the data center lifecycle. As a result, data center providers can deliver a globally consistent experience to address the expanding digital infrastructure needs of their clients.

“At a time when the world’s digital infrastructure is being pushed to its limits, Schneider and AVEVA are delivering a comprehensive solution for hyperscale data centers to operate and maintain their critical environments,” said Pankaj Sharma, Executive Vice President of the Secure Power Division at Schneider Electric. “The solution can take data that has long been managed at individual data centers, often in siloed sub-systems, normalize it across multiple sites and can ultimately inform and provide enterprise level IT/OT/IoT integration to deliver real-time decision making. The complete solution will deliver operational efficiency and a more reliable data center fleet.”

“AVEVA and Schneider Electric’s unique partnership is already delivering tremendous value for our industrial customers across the board,” said Craig Hayman, CEO, AVEVA. “It is a major strategic milestone for us to extend the partnership into new markets and reach more clients, combining AVEVA’s strong heritage of delivering end-to-end unified solutions with Schneider Electric’s deep data center expertise and global execution capabilities. Our joint customers are empowered by the standardized systems and processes resulting in improved workforce efficiency across multiple sites and the entire enterprise.”

For more information on AVEVA Unified Operation Center for Data Centers click here. For more information on Schneider Electric EcoStruxure for Data Centers and deployment support click here.

About AVEVA

AVEVA is a global leader in engineering and industrial software driving digital transformation across the entire asset and operations life cycle of capital-intensive industries. The company’s engineering, planning and operations, asset performance, and monitoring and control solutions deliver proven results to over 16,000 customers across the globe. Its customers are supported by the largest industrial software ecosystem, including 4,200 partners and 5,700 certified developers. AVEVA is headquartered in Cambridge, UK, with over 4,400 employees at 80 locations in over 40 countries.

About Schneider Electric

At Schneider, we believe access to energy and digital is a basic human right. We empower all to make the most of their energy and resources, ensuring Life Is On everywhere, for everyone, at every moment. We provide energy and automation digital solutions for efficiency and sustainability. We combine world-leading energy technologies, real-time automation, software and services into integrated solutions for Homes, Buildings, Data Centers, Infrastructure and Industries. We are committed to unleash the infinite possibilities of an open, global, innovative community that is passionate about our Meaningful Purpose, Inclusive and Empowered values.

Dr. Jeffrey A. Graves, New President and CEO, 3D Systems

Dr. Jeffrey A. Graves, New President and CEO, 3D Systems

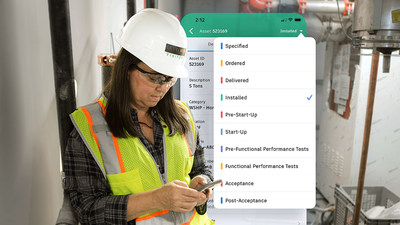

Automatic label placement menu

Automatic label placement menu Drafting co-pilot to assist with the layout of long cable runs

Drafting co-pilot to assist with the layout of long cable runs nhanced wire detailing for accurate cable protection selection

nhanced wire detailing for accurate cable protection selection