ROCK HILL, SC, USA, Feb 5, 2020 – 3D Systems (NYSE:DDD) announced an expanded relationship with Sanmina, a global leader in integrated manufacturing services, to manufacture certain plastic 3D printing platforms. This latest agreement builds on an existing multi-year relationship that originally included the manufacturing of 3D Systems’ Figure 4 platform, and will now expand to include all plastics hardware at its Marine Drive manufacturing facility in Rock Hill, South Carolina. Relying on Sanmina’s global scale and industry-leading manufacturing capabilities enables 3D Systems to focus more capital investments in R&D, plastics material manufacturing, software, application development, and services to accelerate innovation and maintain competitive advantage.

“Three years ago, 3D Systems set out to have world-class manufacturing capabilities for our products,” said Phil Schultz, executive vice president, operations, 3D Systems. “We’ve had an ongoing relationship with Sanmina to manufacture our Figure 4 platform, and their expertise with our products, their commitment to quality, their understanding of our operations is incredibly valuable. We’re confident that this expanded relationship with Sanmina will allow us to continue to deliver best-in-class solutions to our customers and will provide 3D Systems greater competitive advantage through a lower cost-structure.”

“We’re excited to grow our relationship with a world-leader in digital manufacturing solutions,” said Mike Giggey, SVP, business development, Sanmina. “We’re committed to applying our expertise in manufacturing to continue to exceed customer expectations and deliver the highest quality 3D printers available.”

About 3D Systems

More than 30 years ago, 3D Systems brought the innovation of 3D printing to the manufacturing industry. Today, as the leading AM solutions company, it empowers manufacturers to create products and business models never before possible through transformed workflows. This is achieved with the Company’s best-of-breed digital manufacturing ecosystem – comprised of plastic and metal 3D printers, print materials, on-demand manufacturing services and a portfolio of end-to-end manufacturing software. Each solution is powered by the expertise of the company’s application engineers who collaborate with customers to transform manufacturing environments. 3D Systems’ solutions address a variety of advanced applications for prototyping through production in markets such as aerospace, automotive, medical, dental and consumer goods. More information on the company is available at www.3dsystems.com.

Figure 1: New user interface for KOMPAS-3D offering light and dark themes

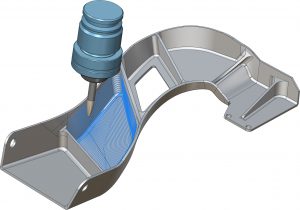

Figure 1: New user interface for KOMPAS-3D offering light and dark themes Figure 2: KOMPAS-3D works faster with 3D models

Figure 2: KOMPAS-3D works faster with 3D models

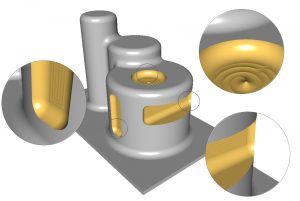

Figures 3 and 4: Algorithmic improvements speed up associative view updates

Figures 3 and 4: Algorithmic improvements speed up associative view updates Figure 5: Inserting mirrored components into an assembly

Figure 5: Inserting mirrored components into an assembly

Winners of the 2019 Enlighten award were presented the award and recognized at the CAR MBS event in Traverse City, MI

Winners of the 2019 Enlighten award were presented the award and recognized at the CAR MBS event in Traverse City, MI

Figure 1. Unfold a 3D tube with BLACK-CAD to see the size of the 2D cutting sheet

Figure 1. Unfold a 3D tube with BLACK-CAD to see the size of the 2D cutting sheet Figure 2. View the curved surfaces from different angles with BLACK-CAD

Figure 2. View the curved surfaces from different angles with BLACK-CAD Kathleen Mitford, CSO, PTC

Kathleen Mitford, CSO, PTC

John Gaeta

John Gaeta