AACHEN, Germany, Sep 1, 2025 – ModuleWorks announces the 2025.08 release of its software components for digital manufacturing and digital factory. With a focus on utilizing integrated information, this latest release of the ModuleWorks SDK comes with automated features designed to enhance process safety, toolpath generation efficiency and part quality.

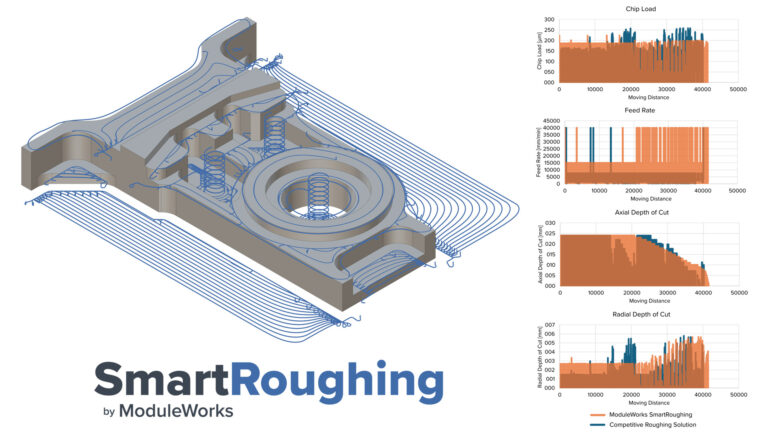

SmartRoughing

Setting the right parameters for roughing often relies on programmer experience to balance material removal, tool wear and machine stability, which can result in conservative choices, longer cycle times and inconsistent results.

With SmartRoughing, ModuleWorks introduces a physics-driven toolpath algorithm that removes the guesswork. By using information on the machine’s capabilities, tool geometry and material properties, SmartRoughing automatically generates toolpaths with constant engagement and optimized chip load. This enables programmers and machine shops to achieve faster machining, longer tool life and more consistent quality while making roughing processes accessible to less experienced users.

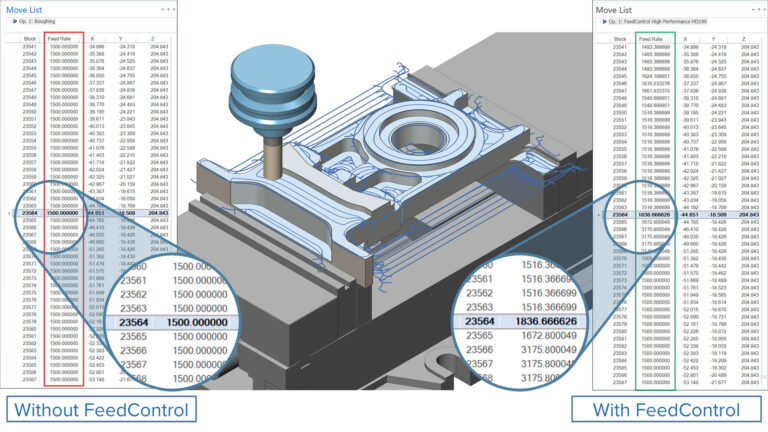

FeedControl

Ensuring consistent chip formation is one of machining’s toughest challenges, with heat, tool load, spindle deflection and material hardening making the process unpredictable and difficult to control.

ModuleWorks 2025.08 introduces FeedControl, an intelligent feed rate optimization technology that balances chip thickness, cutting forces and spindle loads in real time. By adapting to machine-tool capabilities, tool geometry and material behaviour, FeedControl is designed to ensure process stability, protect tools and deliver consistent results.

High Dynamic Turning

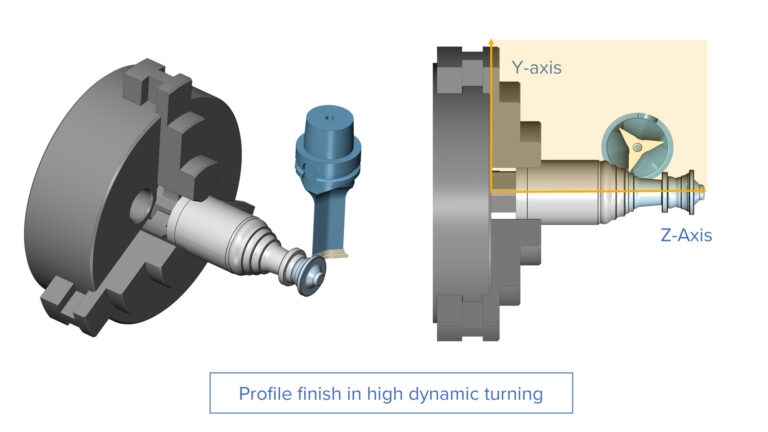

In conventional turning, machining contours requires multiple tools, leading to higher tooling costs and longer cycle times due to frequent tool changes. In addition, traditional turning does not accommodate toolpaths in the Y‑Z plane, restricting process flexibility and efficiency.

The new ModuleWorks 2025.08 turning feature in combination with the FreeTurn tool removes these limitations. A single tool can now machine all contours of a workpiece in one operation, while toolpaths are created directly in the Y‑Z plane. This significantly reduces cycle times through fewer air cuts and tool changes and enables faster feed rates for more efficient machining.

Deburring – Exclude Holes and Vertical Edges

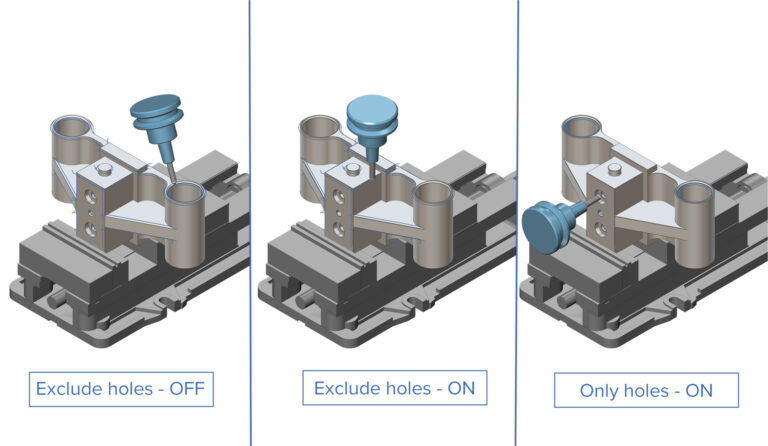

In conventional workflows, deburring holes often requires multiple passes with a spot drill with no option to exclude smaller holes. At the same time, in 3‑axis setups vertical edges cannot be filtered out, leading to additional rework.

To solve this, ModuleWorks 2025.08 introduces a new deburring enhancement that allows users to filter out holes by diameter and exclude vertical edges directly within the toolpath calculation. This gives programmers greater control, reduces redundant work and ensures deburring strategies match the exact requirements of the cutting process.

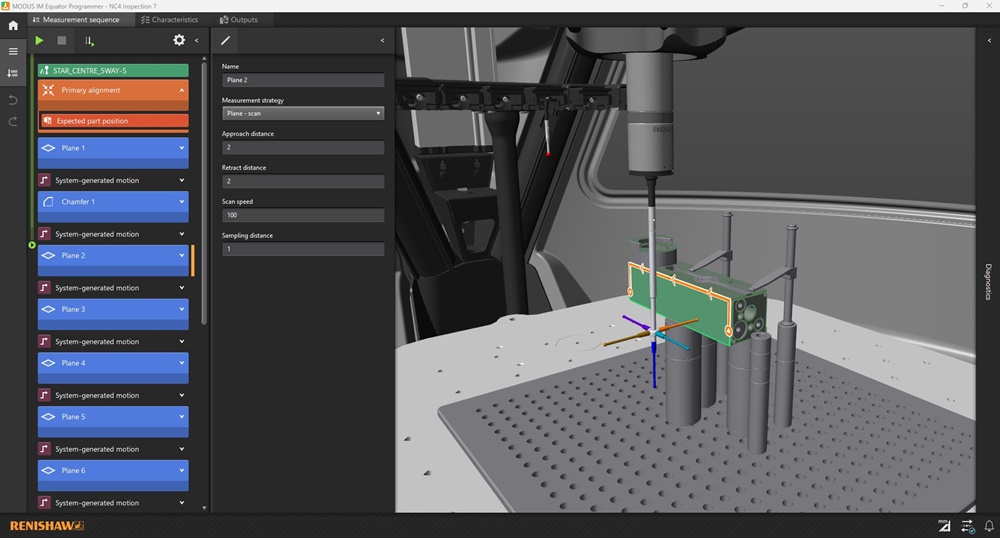

Cutting Simulation – Pixel-Perfect GPU Renderer

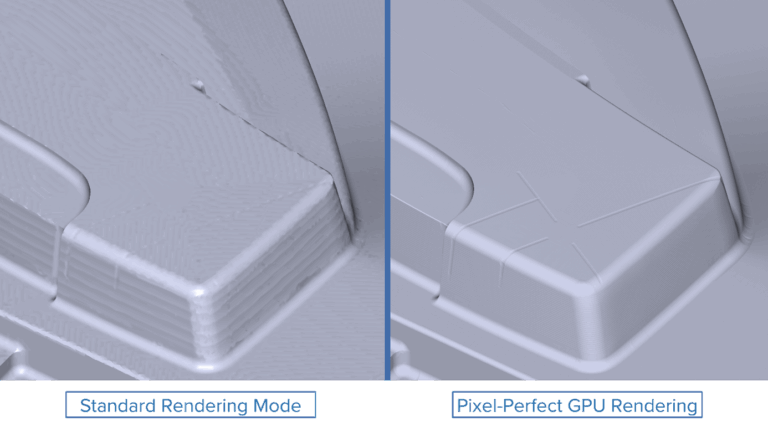

Standard rendering modes often fall short in delivering the visual fidelity required for high-precision machining and fine-detail inspection. Inaccurate or blurry representations of the stock state can make reliable part inspection and deviation analysis difficult.

ModuleWorks 2025.08 addresses this issue with a new GPU-accelerated rendering feature that generates pixel-perfect visuals whenever the camera is idle. It gives machinists and inspectors a highly detailed and accurate view of the current stock, making it easier to spot deviations and verify machining results with confidence. The sharp inspection visuals lead to trustworthy analyses, enhancing quality control and supporting high-precision requirements in modern manufacturing environments.

Availability

ModuleWorks 2025.08 is available for download from the ModuleWorks website.

For more details about these and the other new features and enhancements in the ModuleWorks 2025.08 release, please see the ModuleWorks What’s New webpage.

About ModuleWorks

ModuleWorks is at the forefront of digital manufacturing software, playing a key role in enabling the efficient production of increasingly complex parts in an environmentally sustainable way. As a strategic partner to leading CAD/CAM vendors, CNC control makers, machine tool builders and cutting tool manufacturers, ModuleWorks develops software that powers solutions throughout the manufacturing industry which contributes to 16% of global GDP worth $16 trillion per year.

Founded in 2003, ModuleWorks has grown to over 200 developers and already invested 2000 person-years of software development in toolpath and simulation technologies that form the core of manufacturing processes. In the CAD/CAM area alone, ModuleWorks has a market share of 90%, enhancing the performance and quality of over 500,000 installed seats of CAD/CAM and CNC software worldwide. With a comprehensive portfolio of cutting-edge software components and the capacity to address emerging and niche technologies like AI, cloud, automation, additive, robotics and digital dentistry, ModuleWorks is committed to shaping the future of digital manufacturing with its partners, empowering the industry to Get There Faster.