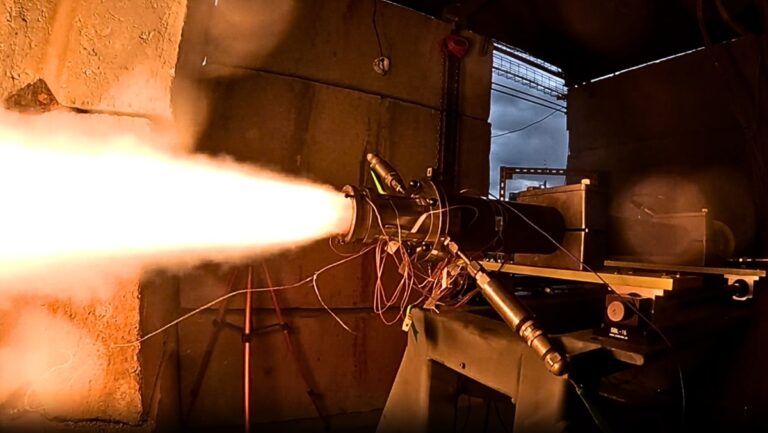

DENVER, CO, USA, Aug 28, 2025 – Ursa Major, in collaboration with BAE Systems, has completed a series of successful static fires for a new extended range variant of the solid rocket motor used for the APKWS laser-guidance kit. This next-generation rocket motor incorporates Ursa Major’s Highly Loaded Grain propellant technology, delivering enhanced range and performance without increasing the motor’s size.

The milestone marks significant progress toward a flight test demonstration planned for fall 2025, underscoring Ursa Major’s ability to rapidly develop, test, and deliver propulsion systems that meet urgent warfighter needs.

“Our collaboration with BAE Systems to extend the range of the APKWS guided rocket demonstrates how Ursa Major is accelerating SRM capability through innovation and speed,” said Dan Jablonsky, CEO of Ursa Major. “These successful tests validate our approach and set the stage for a flight test this fall and our ramp to provide critical SRM production capacity.”

Ursa Major’s HLG technology enables longer-range missile capabilities while maintaining the original form factor. This flexible design architecture supports reuse of manufacturing systems across multiple missile systems and integrates with Ursa Major’s Lynx Manufacturing System, a software-enabled, additive manufacturing production line that delivers scalability and speed without the bottlenecks of legacy industrial processes.

BAE Systems’ APKWS guidance kit transforms unguided 2.75-inch rockets into smart laser-guided rockets for precision strikes. The guidance kit redefines precision munitions by hitting targets with pinpoint accuracy and minimal collateral damage, delivering critical lethality when it matters most. The kits are available to all U.S. armed forces, as well as allies via Foreign Military Sales.

By combining proven hardware, rapid production, and a mission-agnostic manufacturing line, Ursa Major is reshaping the solid rocket motor landscape, unlocking urgently needed capacity for the U.S. and its allies.

This successful static fire comes after the announcement validating similar capabilities of both 10” diameter and 5” diameter SRMs.

About Ursa Major

Ursa Major is an aerospace and defense company delivering flight-proven capabilities for hypersonics, solid rocket motors, in-space propulsion, and launch. Headquartered in Berthoud, Colorado, with additive manufacturing operations in Youngstown, Ohio, Ursa Major leverages advanced production techniques and flexible architectures to build systems for all domains: land, air, sea, and space. The company is revitalizing the defense industrial base for the U.S. and its allies, flying faster to accelerate delivery of critical capabilities where speed and adaptability matter most. For more information, visit https://www.ursamajor.com.

About BAE Systems

BAE Systems, Inc. and its nearly 41,000 people are part of a global defense, aerospace, and security company with approximately 100,000 employees worldwide. We deliver products and services for air, land, sea and space, as well as advanced electronics, intelligence, security, and IT solutions and support services. Our dedication shows in everything we design, produce and deliver— to protect those who protect us in a high-performance, innovative culture. We push the limits of possibility to provide a critical advantage to our customers where it counts. For more information, visit https://www.baesystems.com.