LEUVEN, Belgium, Jul 22, 2024 – Materialise, a global leader in 3D printing software and services, has acquired FEops, a Belgian company that develops AI-driven simulation technology to improve procedure efficiency and clinical outcomes for structural heart interventions. The acquisition will allow Materialise to expand its cardiovascular solutions with predictive simulation capabilities, advancing the personalized treatment of patients with heart diseases. The amount of the transaction was not disclosed. Increased mass personalization, enabled by 3D technologies, is enhancing healthcare by enabling tailored treatment plans and interventions that cater to the unique anatomy of individual patients, resulting in improved outcomes and patient satisfaction.

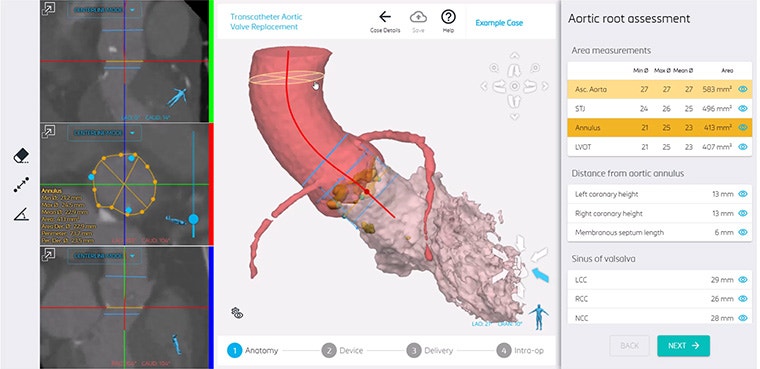

FEops combines predictive simulation technology and artificial intelligence, allowing clinicians to more accurately predict how transcatheter structural heart devices will interact with a patient’s anatomy. Materialise’s Mimics Planner for Structural Heart Interventions, an industry-standard solution for segmentation and anatomical analysis, planning, and design, enables the creation of accurate virtual 3D models based on medical image data.

With the integration of FEops, the Mimics Planner will offer a comprehensive solution for anatomy-based 3D planning and AI-based simulation, allowing clinicians to simulate the interaction between a medical device, such as a heart valve, and a patient’s unique anatomy. This advancement is set to transform patient care for structural heart diseases by offering a more interactive and AI-based solution for preparing heart procedures.

“At Materialise, we are pioneering the advent of mass personalization in healthcare, using advanced visualization and 3D printing technologies to deliver precise, patient-specific solutions,” said Brigitte de Vet, CEO of Materialise. “By integrating FEops’ advanced predictive simulation technology with our Mimics Planner, we are expanding our cardiovascular solutions to provide clinicians with comprehensive insights into patient anatomy. This integration will not only enhance the accuracy and efficiency of structural heart interventions but also improve clinical outcomes and patient safety.”

Historically, transcatheter procedures were reserved for the most complex cases and high-risk patients, but these procedures are becoming more common today. However, challenges remain in evaluating patient eligibility for transcatheter interventions and assessing potential risks and adverse events. Enhanced visualization and simulation technologies are essential in improving the clinical workflow, thereby expanding the availability of transcatheter procedures to a broader range of patients and improving overall outcomes.

Structural heart diseases, like heart valve diseases, represent a significant medical and economic challenge, being the leading cause of cardiovascular morbidity and mortality worldwide. Currently, 47 million people suffer from heart valve diseases, and this number is steadily increasing. By 2030, the annual costs associated with adverse outcomes are projected to reach 70 billion USD globally.

Materialise is advancing mass personalization in healthcare by facilitating the creation of image-based virtual 3D models for pre-procedural planning, enhancing the precision and success of complex procedures. These models enable the creation of personalized medical devices, guides, and implants tailored to the precise anatomical specifications of individual patients. This level of personalization enhances patient outcomes and makes personalized healthcare more efficient and accessible to more patients.

About Materialise

Materialise incorporates more than three decades of 3D printing experience into a range of software solutions and 3D printing services that empower sustainable 3D printing applications. Our open, secure, and flexible end-to-end solutions enable flexible industrial manufacturing and mass personalization in various industries — including healthcare, automotive, aerospace, eyewear, art and design, wearables, and consumer goods. Headquartered in Belgium and with branches worldwide, Materialise combines the largest group of software developers in the industry with one of the world’s largest and most complete 3D printing facilities. For more information, visit https://www.materialise.com.