LEUVEN, Belgium, Nov 9, 2023 – Materialise, a global leader in 3D printing software and service solutions, has announced technological advances to drive the adoption of additive manufacturing (AM) for volume production and end-use part manufacturing. The company is presenting them at Formnext (Frankfurt a. M., Germany), which is taking place from Nov. 7 – 10.

Bringing light to the AM black box

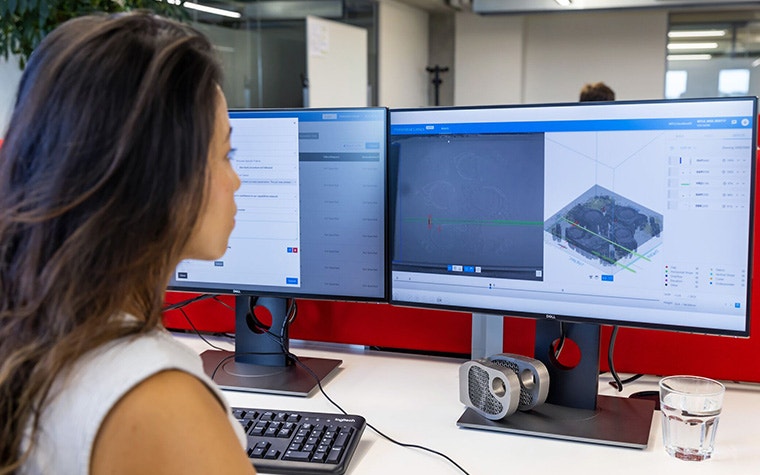

Materialise introduces the CO-AM Quality & Process Control (QPC) system, a software solution for companies that want to take AM quality and process control in certified manufacturing to the next level. QPC will enable them to track, monitor, analyze, and correlate all data critical to part quality. It interconnects AM data sources like 3D models, raw materials, process parameters, in-situ process monitoring, post-processing, and quality inspection. QPC users can collect and monitor this data during the different stages of product development, like research, validation, and production. This will help them to get an unparalleled holistic view of their process and its interrelationships.

Earlier this year, Materialise introduced the first QPC Layer Analysis module, a software to analyze and correlate layer data from the 3D printing process. The QPC Layer Analysis module has been further developed to include more in-situ process monitoring data sources and to correlate its results with CT scans. The new QPC Process Lab module fosters collaboration of different teams to centralize research and production data in a structured way. This allows them to accelerate product development, support process validation, and seamlessly monitor process stability and material properties from research to actual production.

The QPC system is part of the Materialise CO-AM Software Platform. CO-AM gives manufacturers access to a full range of software tools to plan, manage, and optimize every step of the 3D printing process. It provides access to complementary solutions from Materialise and third parties, including CO-AM partner solutions for design automation, mass customization, automated labeling, and various post-processing technologies. CO-AM enables AM users to connect and manage technologies from different machine builders over one platform.

Speed and transparency for customers

Manufacturing customers are expecting responses 24/7 and a fast quote turnaround time. Very often, traditional order processing is a lengthy task via phone and email, often combined with scattered data in isolated locations. This increases administrative overhead, causing service bureaus unnecessary costs. However, accessibility, high responsiveness, and fast delivery are paramount for 3D printing manufacturers as flexible order management, fast time-to-market, and delivering time-sensitive parts on short notice are vital benefits for their customers.

“It’s time to prioritize customer experience in B2B, especially when enabling AM service bureaus,” shares Pieter Hens, Senior Partner Manager. “Integrating DigiFabster’s solution into CO-AM closes the gap between front-end and back-end.”

Materialise collaborates with DigiFabster, a cloud-based SAAS quoting automation and e-commerce solution for advanced manufacturing companies. DigiFabster’s eCommerce portal, automated quoting, costing, and payment automation will be integrated into the Materialise CO-AM software platform.

The fully white-labeled e-commerce portal uses machine learning to help manufacturers automate and accelerate their quoting process, saving time and costs. At the same time, their customers can get quotes around the clock. To facilitate customer support and accelerate business processes, the CO-AM integration enables the streamlining of order data into CO-AM’s Order Management System. This will help manufacturers keep track of orders and give instant status updates to their customers.

“Speed and reliability are essential for manufacturing companies,” explains Const Ivanov, CEO of DigiFabster. “Working with Materialise, we will be able to offer a digital manufacturing workflow that offers a modern customer experience and helps get paid on time. This partnership will offer significant value to our customers.”

Driving simulation for the AM process

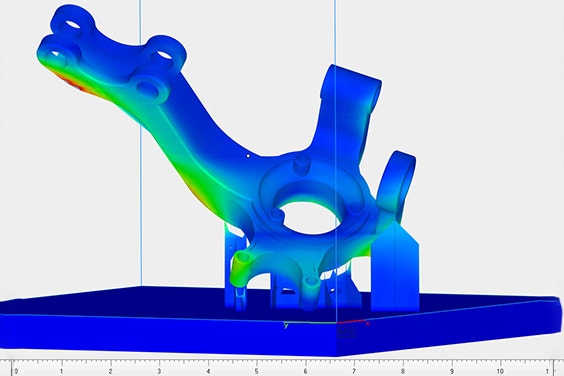

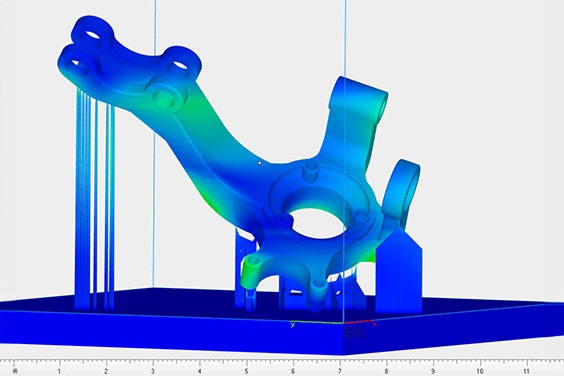

Ansys and Materialise have announced a partnership to drive the integration and performance of simulation for the 3D printing process. AM users often have to use one application for data and build preparation and switch to another to run simulations. This slows down build optimization and preparation and requires expert knowledge that occupies costly engineering capacities. Materialise and Ansys’ partnership will make simulation more accessible for all Materialise Magics users, helping them drive down costs and work more efficiently.

“Usability and performance are crucial when it comes to simulation,” explains Chris Robinson, Senior Product Manager, Ansys. “By integrating Ansys technology into Materialise’s comprehensive software solutions, AM users can benefit from a seamless workflow using the gold standard in simulation.”

As a first step of their partnership, Ansys’ highly acclaimed simulation technology, Ansys Additive Suite, has been introduced into Magics, Materialise’s leading data and build preparation software. This will create a seamless workflow, offer fast simulation, and lower the complexity of applying simulation results to the build preparation. Ansys and Materialise plan to explore further opportunities for simulation in the AM process.

“We look forward to supporting our customers with Ansys technology,” says Karel Brans, Senior Director of Partnerships. “Simulation is a key element for metal 3D printing to improve cost-efficiency. Ansys and Materialise will work together to integrate simulation technology even further into the AM workflow and offer unparalleled connectivity.”

Making AM a reality for serial production of end-use parts

Together with its partners, Materialise has proven that AM is a viable solution for the volume production of identical and unique end-use parts. At Formnext, Materialise will present successful use cases showcasing volume production in different industries, including medical technology, automotive, and aerospace. Demonstration parts include applications from highly regulated industries. For example, biotech company Sartorius ordered more than 26,000 biocompatible plastic parts for bioreactors used in life science research and drug production over the last five years. By choosing AM as a price-competitive technology for small series production, Sartorius created design optimizations and was able to shorten time-to-market.

Other companies apply 3D printing to develop completely novel solutions. CMB.TECH, which builds, owns, operates, and designs large green marine and industrial applications, delivers sustainable innovation enabled by metal 3D printing. CMB.TECH’s hydrogen-diesel dual-fuel technology converts existing diesel engines into hybrids in which hydrogen is aspirated into the combustion chamber using a 3D-printed injection ring. As a first step, they converted different types of heavy-duty equipment, including trucks, and turned to Materialise to manufacture the parts.

“Everything from machining to the assembly process is much simpler when you can remove the complexity in the build phase by using AM. Materialise takes care of all of it, so we receive a fully finished part,” explains Roy Campe, Chief Technology Officer of CMB.TECH.

The CMB.TECH solution will be exhibited for the first time during Formnext.

In addition to 3D printing for serial production, Materialise will showcase a new post-processing technology from its manufacturing portfolio. Materialise is one of the first manufacturers to apply Reinforce3D’s new Continuous Fibre Injection Process (CFIP). This technology enables the reinforcement of 3D-printed parts by injecting them with continuous fibers, such as carbon fibers, using resin as a lubricant to carry the fibers deep into hollowed sections. Once the mixture of resin and fibers cures, they enhance the strength of the part’s structure, providing ultra-high mechanical and light-weighting performance. Materialise will display parts improved with the new post-processing technology at Formnext.

Materialise will present 3D printing software solutions and 3D printing cases at booth C139 in hall 12.1 during Formnext in Frankfurt a. M., Germany, November 7 – 10.

About Materialise

Materialise incorporates more than three decades of 3D printing experience into a range of software solutions and 3D printing services that empower sustainable 3D printing applications. Our open, secure, and flexible end-to-end solutions enable flexible industrial manufacturing and mass personalization in various industries — including healthcare, automotive, aerospace, eyewear, art and design, wearables, and consumer goods. Headquartered in Belgium and with branches worldwide, Materialise combines the largest group of software developers in the industry with one of the world’s largest and most complete 3D printing facilities. For more information, visit https://www.materialise.com.