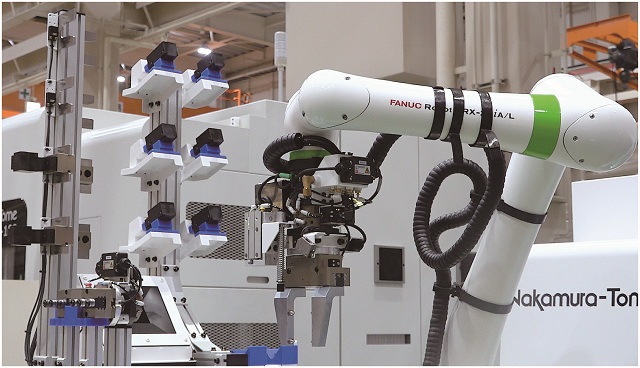

HAKUSAN, Ishikawa, Japan, Sep 24, 2025 – Nakamura-Tome Precision Industry Co., Ltd. (CEO Shogo NAKAMURA) has announced its new robotic system, “RoboSync,” designed to automate the transfer of materials and finished products by connecting to machinery.

“RoboSync” is a flexible automation system equipped with a standard vision sensor. It eliminates the need for a dedicated work stocker*, allowing users to utilize existing pallets, carts, and other storage solutions for materials and finished products. The system was developed to meet the growing demand for simple and accessible automation without the need for large-scale setups.

Furthermore, “RoboSync” can be connected to a wide range of machines—including machine tools, cleaning equipment, and measuring devices—regardless of manufacturer or NC specifications.

The Type D specification of RoboSync includes a work stocker and an automatic exchange rack mounted on the RoboSync mounting base, enabling automation for a wide variety of products.

Compact and Automated for Multiple Product Types – A New Solution to Labor Shortages, https://youtu.be/efsiUqd7btw.

Highlights:

Multi-Product Automation System

RoboSync [Type D] is equipped with a work stocker and an automatic exchange rack, both mounted on a base unit. The shelf-type work stocker can be accessed from either side, enabling operators to load materials into other drawers from the opposite side while the robot is operating.

Various automatic changeover functions can be added as options. By storing workpiece grippers, chuck jaws, and end effectors (such as gripper or jaw-changing hands) in an automatic changeover rack, RoboSync can automatically perform setup changes when switching workpiece types, reducing operator workload.

Space-Saving Design

By adopting a collaborative robot, RoboSync eliminates the need for safety fences. In addition, with the stocker built into the base frame, there is no need for a separate stocker, further reducing the required footprint. Despite being a multi-product automation system, RoboSync achieves a compact, space-saving layout.

Quick Recovery

Positioning between machines (machine tools or other equipment), the robot, and the work stocker (pallets, carts, etc.) is handled using vision sensors and markers. Thanks to this system, even if the robot is moved, it can be quickly restored to its original position by reading the markers on both the machine side and the stocker side.

In many conventional robot systems, once installed, robots and stockers can obstruct access, making machine setup more difficult. With RoboSync, the robot can be easily detached, relocated, and then returned to its original setup just as easily.

Easy Operation

RoboSync comes with a dedicated operation screen built into the teaching pendant, allowing the robot to be operated with ease. In addition to entering the necessary information for operation and performing manual controls, it also includes convenient features that support setup and recovery.

To know more about RoboSync, visit https://www.nakamura-tome.com/products/automation/robosync/

For more information about Nakamura-Tome and its products, visit https://www.nakamura-tome.com/contact_product.