GLOUCESTERSHIRE, UK, Aug 8, 2022 – Spindle probes for CNC machine tools can be highly repeatable, but their performance relies on accurate calibration. Renishaw has developed a simple solution to overcome the challenges associated with the manual probe calibration process while consistently achieving high levels of repeatability. Accurate calibration ensures the probe’s performance is repeatable within the machine tool environment.

Today, many users perform the probe calibration process manually, which can cause variability even among skilled operators. Inaccurate probe calibration can affect all subsequent measurements; ACS-1 addresses this via a lockable mechanism that removes the need to use precision gauge blocks or slip gauges.

Introducing the ACS-1 process

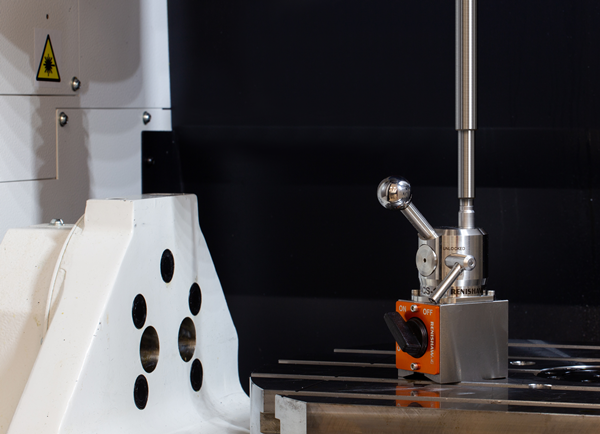

ACS-1 is mounted on the machine tool table or chuck using its magnetic base. A test bar (or a tool of known length) establishes an accurate datum surface by pushing the plunger down to the desired position; the plunger is locked in place. The probe’s overall length can be accurately calibrated, using the calibration disk (the top surface of the lockable plunger). The probe’s stylus ball diameter calibration takes place on the Datum sphere, which can be mounted in two different positions on ACS-1, according to the CNC machine configuration.

The advantages of ACS-1

The Datum sphere can be mounted on one of two faces, both at a 45-degree angle. The mounting options allow ACS-1 to be the ideal probe calibration device for various CNC machine tool configurations. This includes vertical mills, lathes, turn-mills, and 5-axis machines, as the magnetic base allows the artefact to be mounted vertically or horizontally.

The ACS-1 can determine the probe’s overall length and stylus ball diameter within minutes, and does not require batteries.

Richard Cox, Design Group Applications Manager for Renishaw’s Machine Tool Products division, said.

“ACS-1 is highly accurate, it reduces manual operation, therefore reducing human error, ensuring quick, accurate measurements. It also sits alongside our fully automated solution, AutoClock, offered by our associate company, MSP.”

Renishaw has engineered a cost-effective solution for simple, accurate probe calibration. ACS-1 is now available to order worldwide.

For further information on ACS-1, please visit www.renishaw.com/acs

About Renishaw

UK-based Renishaw is a world leading engineering technologies company, supplying products used for applications as diverse as jet engine and wind turbine manufacture, through to dentistry and brain surgery. It has over 5,000 employees located in the 36 countries where it has wholly owned subsidiary operations.

For the year ended June 2021 Renishaw recorded sales of £565.6 million of which 95% was due to exports. The company’s largest markets are China, the USA, Japan and Germany.

Throughout its history Renishaw has made a significant commitment to research and development, with historically between 13 and 18% of annual sales invested in R&D and engineering. The majority of this R&D and manufacturing of the company’s products is carried out in the UK.

The Company’s success has been recognised with numerous international awards, including eighteen Queen’s Awards recognising achievements in technology, export and innovation.

Further information at www.renishaw.com.