GLOUCESTERSHIRE, UK, Nov 6, 2023 – Global engineering technologies company Renishaw will unveil previously unseen metal additive manufacturing (AM) technology at Formnext 2023, being held in Frankfurt, Germany. The upgrade to the bestselling RenAM 500 series of metal additive manufacturing systems will reduce build time by up to half, without any loss of part quality. By lowering cost per part, these innovations will help drive wider industry adoption of AM. From November 7th to 10th, Renishaw will be running daily demonstrations of its new technology at stand C11 in Hall 11.0.

“This launch demonstrates Renishaw’s commitment to putting the best possible AM tools in the hands of the user,” said Louise Callanan, Director of Additive Manufacturing at Renishaw. “To bring AM to the mainstream, Renishaw is addressing what has historically been a huge barrier to AM adoption: productivity. The RenAM 500 metal AM series, already the most productive system on the market, can now build up to twice as fast as before. This dramatic change of pace drives down cost per part and broadens the range of viable applications.”

“As well as supercharging productivity, we want to empower our users with the best possible quality management toolkit,” added Callanan. “By equipping users with data, giving them more control and providing in-process visibility, Renishaw is helping operators gain the confidence needed to move forward. Our new products will help users ensure a solid process foundation and optimal machine performance to consistently produce high quality parts.”

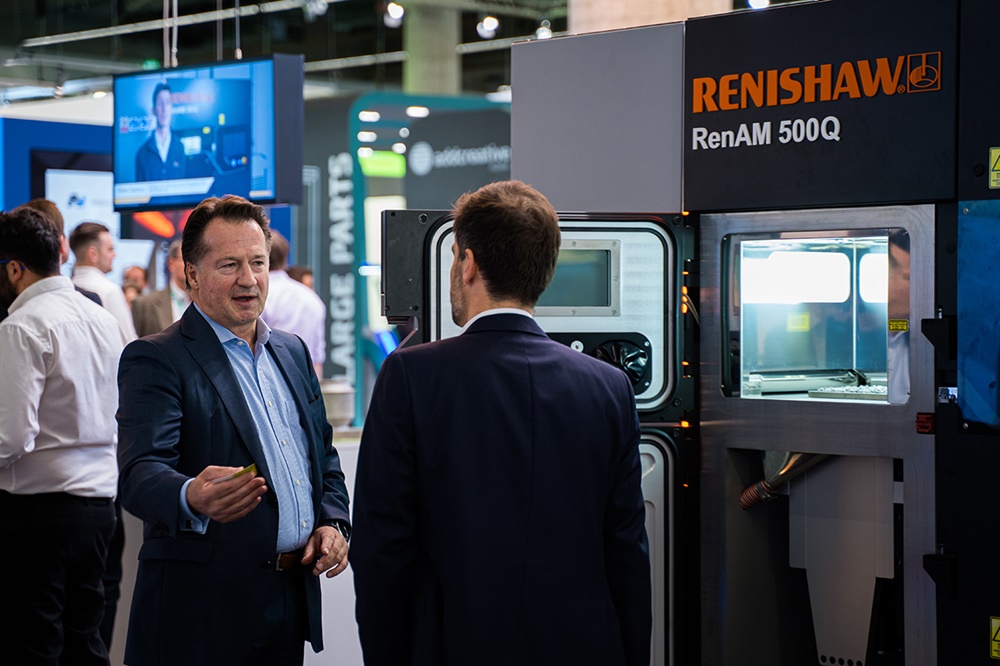

Alongside its new products, the stand will feature Renishaw’s flagship four-laser system, the RenAM 500Q as well as the RenAM 500 Flex, which is optimised for R&D work. These will feature alongside an array of real production parts from Renishaw’s global customer base. Fans of mountain biking will also be excited to see Atherton Bikes’ AM.200M, the ‘fastest bike in the world’; produced using a RenAM 500Q system and ridden to gold medal success by UCI Mountain Bike World Champion Charlie Hatton.

Formnext is one of the world’s leading trade shows for AM and modern manufacturing technology, with over 800 exhibitors, attracting more than 30,000 visitors each year. The show offers a unique insight into the state-of-the-art, focussing on innovations, applications and critical topics affecting the industry such as sustainability, skills and supply chains.

To see a live demo of the new technologies, visit stand C11 in Hall 11.0 at Formnext 2023.

For further information on Renishaw’s additive manufacturing systems, visit Metal 3D printing (renishaw.com)

About Renishaw

Renishaw is a world leading supplier of measuring systems and production systems. Its products give high accuracy and precision, gathering data to provide customers and end users with traceability and confidence in what they’re making. This technology also helps customers to innovate their products and processes.

It is a global business, with over 5,000 employees located in the 36 countries where it has wholly owned subsidiary operations. The majority of R&D work takes place in the UK, with the largest manufacturing sites located in the UK, Ireland and India.

For the year ended June 2022 Renishaw recorded sales of £671.1 million of which 95% was due to exports. The company’s largest markets are China, USA, Japan and Germany.

Renishaw is guided by its purpose: Transforming Tomorrow Together. This means working with customers to make the products, create the materials, and develop the therapies that are going to be needed for the future.

For further information about Renishaw, visit https://www.renishaw.com